Txog kev txiav hlau, peb muaj ntau yam cuab yeej los txiav nws.Tab sis koj puas paub qhov txawv ntawm lawv?

Nov yog qee qhov kev paub uas koj tsis tuaj yeem them tsis tau!

Cov Lus Qhia

-

Cold Saw Basics

-

Kev sib piv nrog cov tsoos sib tsoo log thiab txiav cov ntaub ntawv

-

FAQ txog Cold Saw Siv thiab Installation

-

Xaus

Cold Saw Basics

Cold sawing, los yog hlau txias sawing, yog cov ntawv luv rau cov txheej txheem sawing ntawm hlau ncig saw tshuab. Nyob rau hauv tus txheej txheem ntawm hlau sawing, lub tshav kub generated thaum saws saws lub workpiece yog xa mus rau sawdust los ntawm cov saw hniav, thiab sawed workpiece thiab saw hniav yog khaws cia txias, yog li ntawd nws yog hu ua txias saw.

1. Txias Saw Txiav Nta

High precision ntawm workpiece, zoo nto roughness, zoo txo qhov kev siv ntawm cov txheej txheem tom ntej;

Kev ceev ceev ceev, zoo txhim kho kev tsim khoom;

Qib siab ntawm automation, ib tus neeg tuaj yeem ua haujlwm ntau yam khoom siv, txo cov nqi zog;

Lub workpiece yuav tsis tsim deformation thiab kev hloov hauv lub koom haum;

Cov txheej txheem sawing yog tsawg hauv sparks, plua plav thiab suab nrov.

2: Lub hom phiaj ntawm Sawing

Lub hom phiaj ntawm sawing yog kom ua tiav cov txiaj ntsig zoo sawing

Tom qab ntawd raws li cov hauv paus ntsiab lus saum toj no, peb tuaj yeem kos tus qauv.

Cov txiaj ntsig zoo sawing = cov cuab yeej kev sib koom ua ke sawing + cov saw hlau zoo + cov ntawv thov raug sawing tsis raug

Nyob ntawm cov qauv no, yog li peb tuaj yeem tswj cov nyhuv sawing los ntawm 3 nam.

3: Hlau txias pom - Cov khoom siv ua haujlwm

Processable txiav cov ntaub ntawv:

Channel steel, I-beam, round steel rebar, steel yeeb nkab, aluminium alloy

Cov ntaub ntawv txiav tsis raug:

Stainless hlau (yuav tsum tau saws tshwj xeeb) Hlau hlau quenched thiab tempered steel

Cov no yog qee yam khoom siv uas tuaj yeem txiav thiab cov uas tsis tuaj yeem txiav

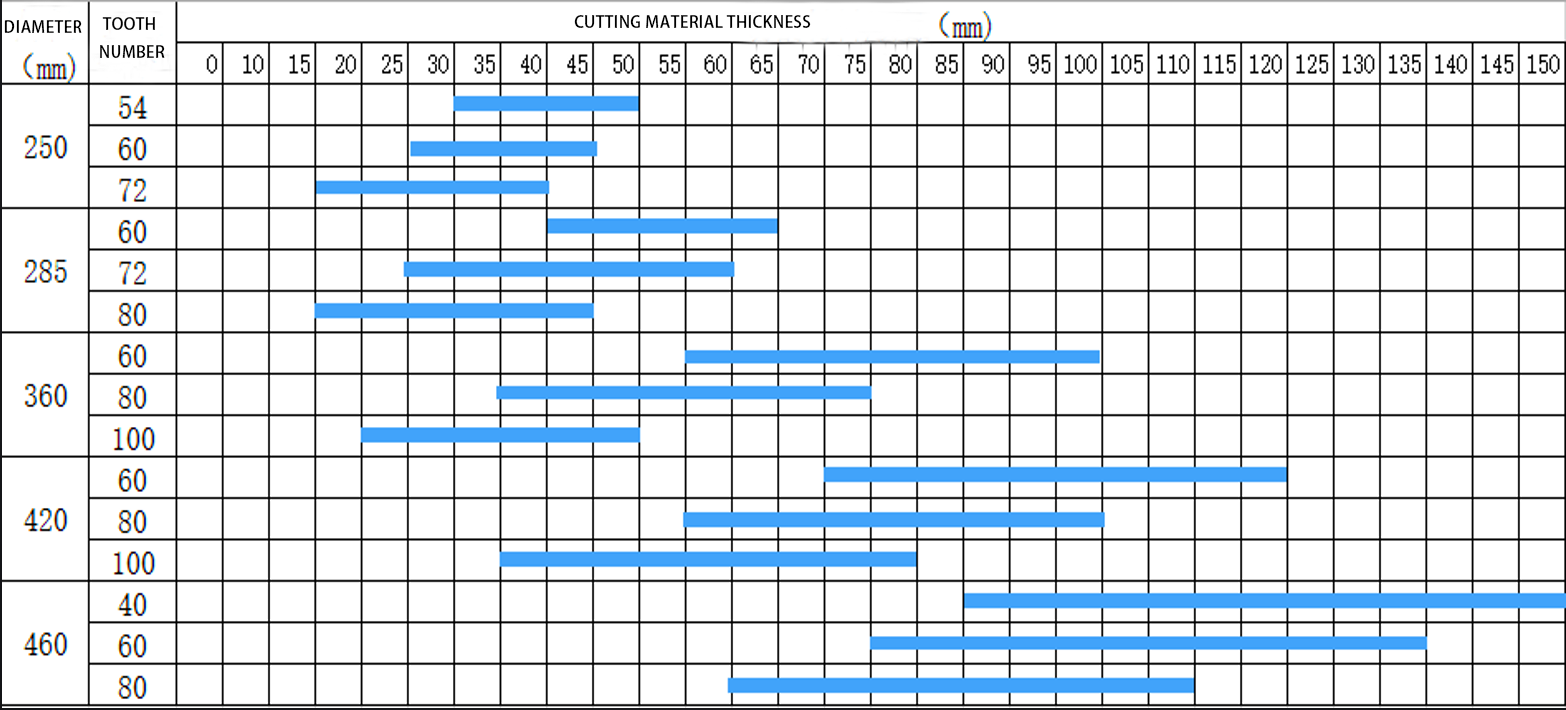

Nyob rau tib lub sijhawm, kev xaiv loj ntawm cov hlau txias pom cov hniav kuj yuav tsum tau ua raws li cov thickness ntawm cov khoom txiav.

Raws li cov lus hauv qab no.

Kev sib piv nrog cov tsoos sib tsoo log thiab txiav cov ntaub ntawv

Sib tsoo Log Disc

Lub txiav disc belongs rau lub sib tsoo log. Nws yog ua los ntawm abrasive thiab binder resin rau txiav cov hlau zoo tib yam, stainless hlau thiab cov khoom tsis yog xim hlau. Nws tau muab faib ua resin txiav disc thiab pob zeb diamond txiav disc.

Siv cov iav fiber ntau thiab cob ua cov ntaub ntawv txuas ntxiv, nws muaj zog tensile, cuam tshuam thiab khoov lub zog, thiab yog siv dav hauv kev tsim thiab blanking ntawm cov hlau zoo tib yam, stainless hlau thiab tsis yog hlau.

Tab sis kev sib tsoo log discs yog siv los ntawm tib neeg. Muaj qee qhov tsis zoo uas tsis tuaj yeem tsis quav ntsej.

Hlau txiav txias saws daws cov ntsiab lus mob no zoo heev.

Hauv dab tsi hauv qab no, peb yuav tham txog cov teeb meem hauv qab no.

1 Kev nyab xeeb

Sib tsoo log disc: tej zaum muaj kev nyab xeeb. Cov neeg khiav dej num tuaj yeem nqus tau ntau qhov teeb meem los ntawm kev sib tsoo lub log disc thaum lub sij hawm txiav cov txheej txheem, ua rau muaj teeb meem kev noj qab haus huv thiab ua rau muaj kev phom sij. Txiav cov ntaub ntawv zoo li muaj lub txim loj.

Tib lub sijhawm, cov ntawv sib tsoo log tawg yooj yim, ua rau muaj kev phom sij zais ntawm cov neeg ua haujlwm kev nyab xeeb.

Kev sib tsoo log hniav hauv kev tsim khoom yuav tsum muaj qhov zoo ruaj khov thiab tsis muaj qhov tsis xws luag, vim tias ib qho saw hniav tawg tuaj yeem tshwm sim los ntawm qhov tsis xws luag. Thaum tawg, nws yuav ua rau neeg raug mob.

Thaum lub sij hawm txiav, nws yog ib qho tsim nyog yuav tsum tau ua tib zoo saib xyuas seb puas muaj cov duab tsis zoo los yog tawg. Yog tias muaj qhov xwm txheej, nws yuav tsum tsis txhob siv thiab hloov lub log sib tsoo tam sim ntawd.

Txias saw: tsis muaj plua plav thiab tsawg sparks thaum txiav. Kev nyab xeeb yog me me. Cov neeg ua haujlwm tuaj yeem siv nws nrog kev ntseeg siab. Nyob rau tib lub sij hawm, qhov zoo thiab hardness ntawm txias saws tau zoo heev zoo dua piv rau kev sib tsoo log.

Lub neej txiav yog ntev dua li ntawm kev sib tsoo disc.

2 Txiav Zoo

Qhov kev ua haujlwm ntawm kev sib tsoo log txiav disc yog qhov tsawg, thiab nws feem ntau yuav tsum tau txiav ntau yam kom ua tiav txoj haujlwm. Tsis tas li ntawd, qhov tseeb ntawm kev sib tsoo lub log yog qhov tsawg, thiab nws nyuaj rau kev ua kom tau raws li qhov xav tau ntawm high-precision txiav.

Kev ua tau zoo yog tsawg, tag nrho cov nqi yog siab, thiab kev siv zog ntawm tus neeg teb xov tooj yog siab vim yog kev sib hloov ceev ntawm cov txheej txheem sib tsoo thiab lub tais cutter, uas ua rau muaj plua plav thiab suab nrov.

Qhov seem ntawm cov khoom txiav yog discolored thiab tsis zoo flatness.

Feem ntau hais lus, cov hniav tsawg dua cov hniav muaj, qhov ceev nws yuav txiav, tab sis kuj yog qhov rougher qhov txiav. Yog tias koj xav tau lub tshuab ntxhua khaub ncaws, txiav kom meej dua, koj yuav tsum xaiv cov hniav nrog cov hniav ntau dua.

Cold Saw Hniav:

Txias txiav: Qhov kub tsim thaum lub sij hawm hlau txias sawing yog qhov qis, uas txo cov thermal deformation hauv cheeb tsam txiav thiab hardening ntawm cov khoom.

Smooth txiav: Muab piv rau cov txheej txheem thermal txiav, hlau txias saws tsim cov txiav txiav, txo qhov xav tau rau kev ua haujlwm tom ntej.

Qhov tseeb: Vim yog kev siv tshuab txias txias, hlau txias saws tuaj yeem muab cov txiav qhov ntev thiab tiaj tiaj.

Kev txiav zoo: Hlau txias saws tuaj yeem txiav tau sai nrog kev kub ceev rotating saw hniav los txhim kho kev tsim khoom. Qhov no ua rau cov saws txias txias zoo heev hauv cov xwm txheej xws li cov khoom ntim siab thiab cov khoom xa tuaj sai uas yuav tsum tau ua kom sai.

Txias sawing kuj muaj qis zog noj thiab ib puag ncig muaj kuab paug. Vim tias cov saws txias siv cov roj nplaum los txo cov cua sov, lawv siv zog tsawg dua cov saw kub. Nyob rau tib lub sijhawm, cov txheej txheem txiav ntawm qhov txias pom yuav tsis tsim cov pa taws thiab cov pa phem, uas txo cov pa phem rau ib puag ncig.

Cov khoom txiav, ntu yog tiaj tus, ntsug tsis muaj burrs.

Siv cov ntaub ntawv zoo, cuam tshuam tsis kam, tsis muaj hniav chipping

3: Txiav cov ntaub ntawv

Flat Steel 1cm * 8cm, 6 vib nas this Bearing Steel 6cm, 11 vib nas this

Square Steel 2cm * 4cm, 3 vib nas thisQhov siab 3.2 cml,3 vib nas this

Round Steel 5cm, 10 vib nas this

Txias saw hniavtsuas yog siv li 10 vib nas this los ua 50mm round steel.

Sib tsoo log txiav disc yuav siv sij hawm ntau tshaj 50 vib nas this los ua 50 round steel, thiab qhov kev tiv thaiv tau loj thiab loj dua.

FAQ txog Cold Saw Siv thiab Installation

FAQ

1: Lub saw hniav yog thim rov qab. Tsis muaj kev taw qhia rau kev sib tsoo lub log, thiab lub tshuab ziab khaub ncaws tsis tuaj yeem siv rov qab.

2: Cov cuab yeej pib sawing ua ntej mus txog qhov kev khiav hauj lwm ceev.

3: Txiav tsis muaj clamping lub workpiece los yog lwm yam kev ua txhaum cai ntawm kev kho lub workpiece arbitrarily.

4: Siv nws ntawm qhov tsis sib xws thaum sawing, ua rau cov txiaj ntsig tsis txaus siab.

5: Thaum txiav sharpness tsis txaus, tshem tawm cov saw nyob rau hauv lub sij hawm, kho nws, thiab ncua lub neej txiav.

Pom Hniav Installation Requirements

-

Lub saw hniav yuav tsum tau ua tib zoo saib xyuas thiab yuav tsum tsis txhob sib tsoo nrog cov khoom txawv teb chaws kom tsis txhob muaj kev puas tsuaj rau cov hniav ntawm ntug lossis deformation ntawm saw hniav lub cev. -

Ua ntej txhim kho cov saw hniav, koj yuav tsum paub meej tias cov flanges sab hauv thiab sab nraud ntawm cov khoom siv tsis pub hnav thiab ua pob kom ntseeg tau tias lawv flatness. -

Paub meej thiab kho qhov hnav ntawm cov hlau txhuam. Yog tias hnav ntau dhau, hloov nws raws sijhawm (tus txhuam hlau ua lub luag haujlwm tseem ceeb hauv kev tshem tawm nti). -

Ntxuav cov roj stains thiab hlau filings ntawm cov ces kaum ntawm cov cuab yeej spindle, hlau txhuam, clamping thaiv, flange thiab tiv thaiv npog kom ntseeg tau tias tsis muaj teeb meem txawv teb chaws. -

Tom qab txhim kho lub saw hniav thiab ua ntej zawm cov ntsia hlau, zawm cov saw hniav nyob rau hauv qhov kev taw qhia tawm kom tshem tawm qhov sib txawv ntawm qhov chaw thiab tus pin positioning thiab tsis txhob txhuam hniav ntawm cov hniav. -

Tom qab paub meej tias cov txiv ntoo raug kaw, kaw lub hau npog lub tshuab, tig lub roj txhaj tshuaj hloov pauv (cov roj yuav tsum txaus), ua haujlwm li 2 feeb, nres lub tshuab thiab xyuas seb puas muaj khawb lossis cua sov ntawm qhov chaw ntawm cov hniav. Kev tsim tawm ib txwm tuaj yeem ua tau tsuas yog tias tsis muaj qhov txawv txav. -

Xaiv cov kev txiav tsim nyog raws li cov yam ntxwv ntawm cov khoom yuav raug txiav. Nyob rau hauv txoj cai, rau cov ntaub ntawv uas nyuaj rau txiav, lub sawing ceev thiab pub ceev yuav tsum tsis txhob ntau dhau. -

Thaum sawing, txiav txim seb lub sawing zoo li cas los ntawm kev soj ntsuam lub suab sawing, txiav nto ntawm cov khoom, thiab cov duab curling ntawm cov ntaub ntawv hlau. -

Thaum txiav nrog lub sawb tshiab, txhawm rau kom muaj kev ruaj ntseg ntawm cov saw hniav, cov kev txiav tsis tuaj yeem ua kom qeeb mus txog li 80% ntawm qhov kev ceev thaum pib txiav (hu ua lub cuab yeej khiav hauv theem), thiab cov sawing rov qab mus rau qhov qub sawing tom qab qee lub sijhawm. txiav ceev.

Xaus

Kev ua hlau yog ib txoj kev ua haujlwm nyuaj hauv kev ua haujlwm ntawm sawing. Vim yog cov yam ntxwv ntawm cov khoom tiav, cov kev xav tau siab thiab cov qauv siab tau txiav txim siab rau kev tsim, tsim thiab siv cov saw hniav.

Piv nrog rau yav dhau los pom cov hniav, qhov pom txias tau daws qee qhov teeb meem zoo, thiab nws tus kheej siab txiav efficiency.

Txias saw yog cov khoom lag luam trending hauv kev ua hlau thiab txiav yav tom ntej.

Peb yeej ib txwm npaj los muab koj cov cuab yeej txiav txoj cai.

Raws li tus neeg muag khoom ntawm lub voj voog saws, peb muab cov khoom zoo tshaj plaws, cov lus qhia khoom, kev pabcuam tshaj lij, nrog rau tus nqi zoo thiab kev txhawb nqa tom qab muag tshwj xeeb!

Hauv https://www.koocut.com/.

Txhaum qhov txwv thiab txav mus tom ntej ua siab tawv! Nws yog peb cov lus hais.

Post lub sij hawm: Sep-01-2023

TCT Saw Hniav

TCT Saw Hniav HERO Sizing Saw Hniav

HERO Sizing Saw Hniav HERO Vaj Huam Sib Luag Sizing Pom

HERO Vaj Huam Sib Luag Sizing Pom HERO Scoring Saw Hniav

HERO Scoring Saw Hniav HERO Khoom Ntoo Pom Hniav

HERO Khoom Ntoo Pom Hniav HERO Aluminium Sawb

HERO Aluminium Sawb Grooving Saw

Grooving Saw Hlau Profile Saw

Hlau Profile Saw Ntug Bander Saw

Ntug Bander Saw Acrylic saws

Acrylic saws PCD Saw Hniav

PCD Saw Hniav PCD Sizing Saw Hniav

PCD Sizing Saw Hniav PCD vaj huam sib luag Sizing Saw

PCD vaj huam sib luag Sizing Saw PCD Scoring Saw Hniav

PCD Scoring Saw Hniav PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Sawb

PCD Aluminium Sawb PCD Fiberboard Pom

PCD Fiberboard Pom Cold Saw rau Hlau

Cold Saw rau Hlau Cold Saw Hniav rau Ferrous Hlau

Cold Saw Hniav rau Ferrous Hlau Dry Cut Saw Hniav rau Ferrous Hlau

Dry Cut Saw Hniav rau Ferrous Hlau Txias Saw Tshuab

Txias Saw Tshuab Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Los ntawm Drill Bits

Los ntawm Drill Bits Hniav Drill Bits

Hniav Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits / Mortise khoom

HSS Drill Bits / Mortise khoom Router khoom

Router khoom Cov khoom ncaj nraim

Cov khoom ncaj nraim Ntev Cov Khoom Ncaj Ncees

Ntev Cov Khoom Ncaj Ncees TCT Cov khoom ncaj nraim

TCT Cov khoom ncaj nraim M16 Cov khoom ncaj nraim

M16 Cov khoom ncaj nraim TCT X Ncaj Ncees

TCT X Ncaj Ncees 45 Degree Chamfer ntsis

45 Degree Chamfer ntsis Carving Bit

Carving Bit Kov Round Bit

Kov Round Bit PCD Router khoom

PCD Router khoom Ntug Banding cuab yeej

Ntug Banding cuab yeej TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Ntug Bander Saw

Ntug Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Ntug Bander Pom

PCD Ntug Bander Pom Lwm yam cuab yeej & Accessories

Lwm yam cuab yeej & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Pob zeb diamond xuab zeb log

Pob zeb diamond xuab zeb log Planer riam

Planer riam