Dab tsi yog qhov teeb meem nrog ntug banding?

Edgebanding yog hais txog ob qho tib si cov txheej txheem thiab cov sawb ntawm cov khoom siv los tsim kom zoo nkauj zoo nkauj trim nyob ib ncig ntawm cov npoo tsis tiav ntawm plywood, particle board, los yog MDF. Edgebanding tsub kom durability ntawm ntau yam ntawm tej yaam num xws li txee thiab countertops, muab lawv ib tug high-end, zoo tsos.

Edgebanding xav tau ntau yam nyob rau hauv cov nqe lus ntawm daim ntawv thov nplaum. Qhov kub ntawm chav tsev, nrog rau cov substrate, cuam tshuam adhesion. Txij li thaum edgebanding yog tsim los ntawm ntau yam khoom sib txawv, nws yog ib qho tseem ceeb uas yuav tau xaiv cov nplaum nplaum uas muaj ntau yam thiab muaj peev xwm ua kom muaj peev xwm sib txuas rau ntau hom substrates.

Kub yaj kua nplaum yog cov nplaum nplaum uas siv ntau hom kev siv thiab haum rau txhua qhov ntug banding xws li PVC, melamine, ABS, acrylic thiab ntoo veneer. Kub yaj yog ib qho kev xaiv zoo heev vim tias nws pheej yig, nws tuaj yeem rov qab ua dua, thiab yooj yim rau kev ua haujlwm nrog.Ib qho tsis zoo ntawm cov nplaum kub yaj nplaum ntug sealing yog tias muaj cov nplaum nplaum.

Txawm li cas los xij, yog tias cov kua nplaum nplaum tau pom tseeb, nws yuav yog tias cov khoom siv tsis tau debugged kom zoo. Muaj peb qhov tseem ceeb: ua ntej milling cutter ib feem, roj hmab cov menyuam chav tsev thiab lub siab rau cov menyuam.

1. Qhov txawv txav ntawm qhov ua ntej milling cutter

-

Yog hais tias lub hauv paus nto ntawm lub pre-milled board muaj ridges thiab cov kua nplaum yog unevenly thov, tsis xws luag xws li cov kua nplaum ntau dhau yuav tshwm sim.Txoj kev los xyuas seb lub pre-milling cutter yog ib txwm yog tua tag nrho cov units thiab tsuas yog tig rau lub pre-milling cutter. Tom qab ua ntej milling MDF, saib seb qhov chaw ntawm lub rooj tsavxwm puas tiaj tus. -

Yog tias lub phaj pre-milled tsis sib npaug, qhov kev daws teeb meem yog hloov nws nrog lub tshuab ua ntej milling tshiab.

2. Cov khoom siv roj hmab cov menyuam yog qhov txawv txav.

-

Tej zaum yuav muaj qhov yuam kev ntawm qhov perpendicularity ntawm cov roj hmab txheej rau cov menyuam thiab lub hauv paus ntawm lub phaj. Koj tuaj yeem siv tus pas ntsuas square los ntsuas qhov perpendicularity. -

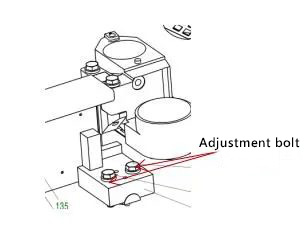

Yog tias qhov yuam kev loj dua 0.05mm, nws raug nquahu kom hloov tag nrho cov milling cutters.Thaum lub pas dej ua kua nplaum yog nyob rau hauv kev lag luam cua sov, qhov kub yog siab li 180 ° C thiab tsis tuaj yeem kov nrog tes liab qab. Txoj kev yooj yim tshaj plaws los kuaj xyuas yog nrhiav ib daim ntawm MDF, kho cov kua nplaum rau qhov tsawg kawg nkaus, thiab saib seb lub qhov kawg ntawm qhov kawg yog txawm nce thiab nqis. Ua me ntsis kev hloov kho los ntawm kev kho cov bolts kom tag nrho lub ntsej muag kawg tuaj yeem sib npaug nrog cov kua nplaum tsawg tshaj plaws.

3. Lub siab lub log tsheb yog qhov txawv txav

-

Muaj cov nplaum nplaum seem nyob rau saum npoo ntawm lub log siab, thiab qhov saum npoo tsis sib npaug, uas yuav ua rau muaj kev cuam tshuam tsis zoo. Nws yuav tsum tau muab ntxuav kom huv si hauv lub sijhawm, thiab tom qab ntawd xyuas seb lub tshuab cua siab thiab lub log siab puas zoo li qub. -

Kev ua yuam kev nyob rau hauv lub verticality ntawm lub xovxwm log kuj yuav ua rau tsis zoo ntug sealing. Txawm li cas los xij, koj yuav tsum xub paub meej tias lub hauv paus ntawm lub rooj tsavxwm yog tiaj tus ua ntej kho qhov ntsug ntawm lub xovxwm log.

Lwm yam tseem ceeb tshaj plaws uas cuam tshuam qhov zoo ntawm ntug banding

1, Cov khoom siv teeb meem

Vim tias lub cav ntawm ntug banding tshuab thiab cov khiav tsis tuaj yeem koom tes zoo, txoj kev khiav tsis ruaj khov thaum lub sijhawm ua haujlwm, ces cov ntug banding strips yuav tsis haum rau ntug zoo kawg nkaus. qhov tsis muaj kua nplaum los yog txheej tsis sib xws feem ntau tshwm sim los ntawm gluing siab pas nrig uas tsis koom tes zoo nrog cov saw hlau conveyor. Yog tias cov cuab yeej trimming thiab cov cuab yeej chamfering tsis raug kho kom raug, tsis tsuas yog yuav tsum tau ua haujlwm ntxiv, thiab qhov zoo ntawm kev txiav yog qhov nyuaj rau lav.

Nyob rau hauv luv luv, vim tsis zoo theem ntawm cov khoom commissioning, kho thiab tu, cov teeb meem zoo yuav kav ntev. Lub blunt ntawm cov cuab yeej txiav kuj ncaj qha cuam tshuam qhov zoo ntawm qhov kawg thiab trimming. Lub trimming lub kaum sab xis muab los ntawm cov cuab yeej yog nruab nrab ntawm 0 ~ 30 °, thiab lub trimming lub kaum sab xis xaiv nyob rau hauv kev tsim khoom yog 20 °. Lub blunt hniav ntawm cov cuab yeej txiav yuav ua rau qhov zoo ntawm qhov chaw txo.

2, Cov khoom ua haujlwm

Cov txiv neej ua ntoo ua cov khoom ntawm workpiece, thickness sib txawv thiab flatness yuav tsis ncav cuag cov qauv. Qhov no ua rau qhov kev ncua deb ntawm lub siab rau cov menyuam lub log mus rau qhov chaw ntawm lub conveyor nyuaj rau teeb. Yog tias qhov kev ncua deb me me dhau lawm, nws yuav ua rau lub zog ntau dhau thiab sib cais ntawm cov strips thiab workpiece. Yog tias qhov kev ncua deb loj dhau, lub phaj yuav tsis raug compressed, thiab cov strips tsis tuaj yeem khi ruaj khov nrog ntug.

3, Ntug Banding Strips

Cov ntug banding strips feem ntau yog ua los ntawm PVC, uas tuaj yeem cuam tshuam zoo rau ib puag ncig. Nyob rau lub caij ntuj no, lub hardness ntawm PVC strips yuav nce uas ua rau cov adhesion rau cov kua nplaum txo. Thiab lub sij hawm cia ntev dua, nto yuav muaj hnub nyoog; lub zog nplaum rau cov kua nplaum yog qis dua. Rau daim ntawv ua strips nrog ib tug me me thickness, vim lawv lub siab toughness thiab tsawg thickness (xws li 0.3mm), yuav ua rau cov txiav tsis sib xws, tsis muaj zog bonding, thiab tsis zoo trimming kev ua tau zoo. Yog li cov teeb meem xws li cov khib nyiab loj ntawm ntug banding strips thiab siab rework tus nqi yog loj.

4, Chav ntsuas kub thiab tshuab kub

Thaum qhov kub hauv tsev qis qis, cov khoom ua haujlwm dhau los ntawm lub tshuab ntug banding, nws qhov kub tsis tuaj yeem nce sai sai, thiab tib lub sijhawm, cov nplaum nplaum yog txias dhau sai heev uas nyuaj rau ua kom tiav kev sib txuas. Yog li ntawd, qhov ntsuas kub sab hauv tsev yuav tsum tswj tau siab tshaj 15 ° C. Yog tias tsim nyog, qhov chaw ntawm ntug banding tshuab tuaj yeem preheated ua ntej ua haujlwm (lub tshuab hluav taws xob tuaj yeem muab ntxiv rau thaum pib ntawm ntug banding txheej txheem). Nyob rau tib lub sijhawm, cov cua kub tso saib qhov kub ntawm lub gluing siab pas nrig yuav tsum sib npaug los yog siab tshaj qhov kub uas cov nplaum nplaum kub yaj tuaj yeem yaj tag.

5, Pub ceev

Kev pub noj ceev ntawm cov tshuab tsis siv neeg ntug banding niaj hnub no feem ntau yog 18 ~ 32m / min. Qee lub tshuab ua haujlwm siab tuaj yeem ncav cuag 40m / min lossis siab dua, thaum phau ntawv nkhaus ntug banding tshuab muaj kev pub noj ceev tsuas yog 4 ~ 9m / min. Kev pub noj ceev ntawm lub tshuab tsis siv neeg ntug banding tuaj yeem hloov kho raws li lub zog ntawm ntug banding. Yog tias qhov kev pub mis ceev dhau lawm, txawm hais tias qhov kev ua tau zoo ntau lawm, cov ntug banding lub zog yog tsawg.

Nws yog peb lub luag haujlwm rau ntug band kom raug. Tab sis koj yuav tsum paub, tseem muaj cov kev xaiv uas koj yuav tsum tau ua thaum ntsuas kev xaiv ntug banding.

Vim li cas thiaj xaiv HERO pre-milling cutter?

-

Nws tuaj yeem ua ntau yam ntaub ntawv. Cov ntaub ntawv tseem ceeb yog board ntom ntom, particle board, multilayer plywood, fiberboard, thiab lwm yam. -

Cov hniav yog ua los ntawm cov khoom siv pob zeb diamond txawv teb chaws, thiab muaj qhov zoo nkauj zoo nkauj ntawm cov hniav tsim heev nrog. -

Kev ywj pheej thiab zoo nkauj pob nrog thawv thiab daim txhuam cev sab hauv, uas tuaj yeem tiv thaiv thaum thauj. -

Nws muaj txiaj ntsig zoo daws qhov tsis xws luag ntawm cov khoom siv tsis zoo thiab hnyav hnyav ntawm carbide cutter. Nws tuaj yeem txhim kho qhov zoo ntawm cov khoom zoo li. Muab lub neej siv ntev. -

Tsis muaj blackening, tsis muaj ntug fragmentation, zoo meej tsos ntawm cov hniav tsim, tag nrho nyob rau hauv txoj kab nrog cov txheej txheem technology. -

Peb muaj ntau tshaj 20 xyoo ntawm kev paub thiab muab kev pabcuam ua ntej muag thiab tom qab muag. -

Kev txiav zoo zoo hauv cov khoom siv ntoo uas muaj fiber ntau.

Post lub sij hawm: Mar-01-2024

TCT Saw Hniav

TCT Saw Hniav HERO Sizing Saw Hniav

HERO Sizing Saw Hniav HERO Vaj Huam Sib Luag Sizing Pom

HERO Vaj Huam Sib Luag Sizing Pom HERO Scoring Saw Hniav

HERO Scoring Saw Hniav HERO Khoom Ntoo Pom Hniav

HERO Khoom Ntoo Pom Hniav HERO Aluminium Sawb

HERO Aluminium Sawb Grooving Saw

Grooving Saw Hlau Profile Saw

Hlau Profile Saw Ntug Bander Saw

Ntug Bander Saw Acrylic saws

Acrylic saws PCD Saw Hniav

PCD Saw Hniav PCD Sizing Saw Hniav

PCD Sizing Saw Hniav PCD vaj huam sib luag Sizing Saw

PCD vaj huam sib luag Sizing Saw PCD Scoring Saw Hniav

PCD Scoring Saw Hniav PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Sawb

PCD Aluminium Sawb PCD Fiberboard Pom

PCD Fiberboard Pom Cold Saw rau Hlau

Cold Saw rau Hlau Cold Saw Hniav rau Ferrous Hlau

Cold Saw Hniav rau Ferrous Hlau Dry Cut Saw Hniav rau Ferrous Hlau

Dry Cut Saw Hniav rau Ferrous Hlau Txias Saw Tshuab

Txias Saw Tshuab Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Los ntawm Drill Bits

Los ntawm Drill Bits Hniav Drill Bits

Hniav Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits / Mortise khoom

HSS Drill Bits / Mortise khoom Router khoom

Router khoom Cov khoom ncaj nraim

Cov khoom ncaj nraim Ntev Cov Khoom Ncaj Ncees

Ntev Cov Khoom Ncaj Ncees TCT Cov khoom ncaj nraim

TCT Cov khoom ncaj nraim M16 Cov khoom ncaj nraim

M16 Cov khoom ncaj nraim TCT X Ncaj Ncees

TCT X Ncaj Ncees 45 Degree Chamfer ntsis

45 Degree Chamfer ntsis Carving Bit

Carving Bit Kov Round Bit

Kov Round Bit PCD Router khoom

PCD Router khoom Ntug Banding cuab yeej

Ntug Banding cuab yeej TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Ntug Bander Saw

Ntug Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Ntug Bander Pom

PCD Ntug Bander Pom Lwm yam cuab yeej & Accessories

Lwm yam cuab yeej & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Pob zeb diamond xuab zeb log

Pob zeb diamond xuab zeb log Planer riam

Planer riam