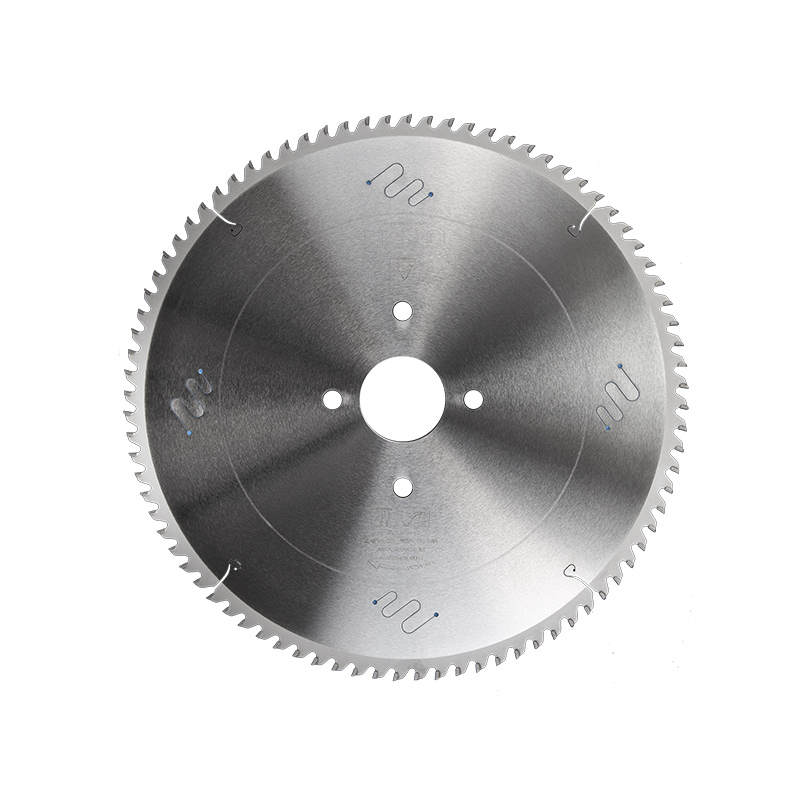

PCD Pom Hniav rau Vaj Huam Sib Luag Sizing Saw Hniav

Product Overview

Raw Khoom:PCD ntu, German imported steel phaj 75CR1 thiab Nyiv imported steel phaj SKS51.

Hom Tshuaj:HERO, LILT

Nta

1. Siv los txiav ntoo vaj huam sib luag thiab muab cov saw hlau ntxiv rau cov khoom siv txiav, MDF, thiab melamine board.

2. Siv rau ntau yam khoom siv, xws li Biesse, Homag, thiab beam saw.

Qhov zoo:

1. Silent tsim nrog Nyiv damping thiab chrome txheej rau txiav tsis muaj suab nrov.

2. Cov khoom siv PCD tau cog lus tias yuav txuas ntxiv lub neej ntawm cov cuab yeej thiab cov hniav.

3. Cov qauv tsim los tiv thaiv kev vibration txo qis kev vibration thiab txhim khu kev ua haujlwm, tiv thaiv chipping thiab tiav txiav.

4. Cov txheej txheem nruj uas ua kom cov saw hniav yog qib siab, ua kom ntau lawm, txo cov sij hawm xav tau rau kev hloov, thiab txo cov cuab yeej siv.

5. Siv cov tshuab Gerling los ua kom tiav cov txheej txheem brazing thiab sandwich nyiaj-tooj liab-nyiaj tshuab los ntxiv dag zog rau cov hniav.

Qhov tseem ceeb:

● 1. Tswj qhov kub thiab txias thaum ua cov ntu PCD.

● 2. Ua kom tiav cov txheej txheem sib tsoo, uas yog cov kauj ruam tseem ceeb tshaj plaws rau PCD saws, siv tooj liab electro sanding log.

● 3. Tus qauv ntev ntawm PCD hniav yog 6.0mm, tuaj yeem kho raws li cov kev cai tshwj xeeb, piv txwv li 6.8mm thiab 7mm. Qhov ntev ntawm PCD ntu ntau lub neej.

● 4. Qhov zoo tshaj plaws yog lub neej ntev ntawm cov cuab yeej, txog 50 npaug ntau dua li TCT carbide tipped saw hniav. Piv txwv li, koj siv 5 zaug nyiaj ntau dua kom tau txais cov khoom lag luam uas ua haujlwm 50 zaug ntev dua, thiab tuaj yeem ua haujlwm 30 hnub ntxiv nrog rau ib qho kev hloov ntawm lub tshuab, uas tseem yuav txuag koj ntau lub sijhawm hloov cov hniav. Koj qhov kev xaiv yuav yog dab tsi?

Tsis muaj

1. Cov khoom no feem ntau yog tsim los txiav rau txiav ntoo panels, particle, laminated thiab MDF ntawm rooj saws thiab vaj huam sib luag sizing saws.

2 .Piv nrog tungsten carbide thiab steel ncig saw hniav, pcd saw hniav yog ib qho nyuaj thiab muaj zog ntau dua, ua tau 30-50 lub sij hawm ntev lub cuab yeej, thiab qhov no txuag tau ob lub sij hawm thiab nyiaj txiag.

3. Tshuab: ob chav miter pom, vaj huam sib luag pom, txiav tawm thiab lwm yam CNC tshuab thiab lwm yam.

4. Daim ntawv thov: muaj tseeb heev rau 45 degree thiab 90 degree sib koom txiav.Tshwj xeeb yog txais tos ntawm txhuas qhov rais lossis qhov rooj tsim khoom.

| OD (mm) | Npog | Kerf Thickness | Phaj Thickness | Tus naj npawb ntawm cov hniav | Sib tsoo |

| 350 | 30 | 4.4 | 3.2 | 72 | TCG |

| 350 | 30 | 4.4 | 3.2 | 84 | TCG |

| 380 | 60 | 4.4 | 3.2 | 72 | TCG |

| 380 | 60 | 4.4 | 3.2 | 84 | TCG |

| 380 | 60 | 4.4 | 3.2 | 96 | TCG |

| 400 | 60 | 4.4 | 3.2 | 72 | TCG |

| 400 | 60 | 4.4 | 3.2 | 84 | TCG |

| 400 | 75 | 4.4 | 3.2 | 84 | TCG |

| 400 | 60 | 4.4 | 3.2 | 96 | TCG |

| 450 | 60 | 4.4 | 3.2 | 72 | TCG |

| 450 | 60 | 4.8 | 3.5 | 84 | TCG |

| 450 | 60 | 4.8 | 3.5 | 96 | TCG |

TCT Saw Hniav

TCT Saw Hniav HERO Sizing Saw Hniav

HERO Sizing Saw Hniav HERO Vaj Huam Sib Luag Sizing Pom

HERO Vaj Huam Sib Luag Sizing Pom HERO Scoring Saw Hniav

HERO Scoring Saw Hniav HERO Khoom Ntoo Pom Hniav

HERO Khoom Ntoo Pom Hniav HERO Aluminium Sawb

HERO Aluminium Sawb Grooving Saw

Grooving Saw Hlau Profile Saw

Hlau Profile Saw Ntug Bander Saw

Ntug Bander Saw Acrylic saws

Acrylic saws PCD Saw Hniav

PCD Saw Hniav PCD Sizing Saw Hniav

PCD Sizing Saw Hniav PCD vaj huam sib luag Sizing Saw

PCD vaj huam sib luag Sizing Saw PCD Scoring Saw Hniav

PCD Scoring Saw Hniav PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Sawb

PCD Aluminium Sawb PCD Fiberboard Pom

PCD Fiberboard Pom Cold Saw rau Hlau

Cold Saw rau Hlau Cold Saw Hniav rau Ferrous Hlau

Cold Saw Hniav rau Ferrous Hlau Dry Cut Saw Hniav rau Ferrous Hlau

Dry Cut Saw Hniav rau Ferrous Hlau Txias Saw Tshuab

Txias Saw Tshuab Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Los ntawm Drill Bits

Los ntawm Drill Bits Hniav Drill Bits

Hniav Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits / Mortise khoom

HSS Drill Bits / Mortise khoom Router khoom

Router khoom Cov khoom ncaj nraim

Cov khoom ncaj nraim Ntev Cov Khoom Ncaj Ncees

Ntev Cov Khoom Ncaj Ncees TCT Cov khoom ncaj nraim

TCT Cov khoom ncaj nraim M16 Cov khoom ncaj nraim

M16 Cov khoom ncaj nraim TCT X Ncaj Ncees

TCT X Ncaj Ncees 45 Degree Chamfer ntsis

45 Degree Chamfer ntsis Carving Bit

Carving Bit Kov Round Bit

Kov Round Bit PCD Router khoom

PCD Router khoom Ntug Banding cuab yeej

Ntug Banding cuab yeej TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Ntug Bander Saw

Ntug Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Ntug Bander Pom

PCD Ntug Bander Pom Lwm yam cuab yeej & Accessories

Lwm yam cuab yeej & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Pob zeb diamond xuab zeb log

Pob zeb diamond xuab zeb log Planer riam

Planer riam