Nzira yekusarudza pakati peSimbi Yekucheka Saw uye Circular Cold Saw?

Kune zvitoro zvakawanda zvesimbi, kana uchicheka simbi, blade sarudzo inogona kuve yakakosha pakuchekwa kwayo uye kunaka.Kuita sarudzo isiriyo kunokanganisa kugadzirwa kwako kwenguva pfupi. Mukufamba kwenguva, inogona kudzikisira mikana yako yekuwana vatengi vanoda kumwe kuchekwa mune chaiyo zvinhu.

Kuti ikubatsire kuita sarudzo yakanaka, unofanirwa kuziva zvakanakira uye zvazvakaipira zvechando chesaha blades uye simbi yenguva dzose yekucheka masaha blades.

Chii chinonzi cold saw

Cold saws anoshandisa denderedzwa saha blade kucheka nemhando dzakasiyana dzesimbi dzinosanganisira sheet simbi. Sezvinoreva zita, saha inotonhora inoita basa rayo nemazvo, uku ichidzivirira blade nesimbi kuti zvisanyanya kupisa. Cold saws anowanzo akasununguka-akamira michina uye kwete iyo bhenji-yepamusoro, inotakurika akasiyana.

Muchina wekucheka unoshandiswa kucheka simbi nekumhanya zvakanyanya pasina kugadzira kupisa kwakanyanya, pfari kana guruva. Cold sawing inoshandisa denderedzwa blade kubvisa zvinhu paunenge uchiendesa kupisa kunogadzirwa kumachipi anogadzirwa nesaha. Kupisa kunogadzirwa panguva yekucheka nesaha inotonhora inotamirwa kune mabhura akaumbwa panzvimbo yeakachekwa zvinhu, saka iyo workpiece inoramba ichitonhora.

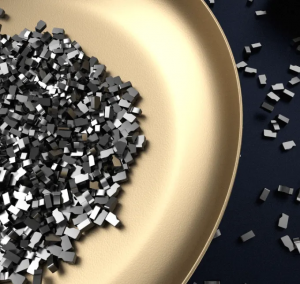

Saha inotonhora inoshandisa ingave yakasimba high-speed simbi (HSS) kana tungsten carbide-tipped (TCT) blade inotenderera pakadzika RPMs.

Kusiyana nezita racho, HSS blades haawanzo shandiswa pakumhanya kwakanyanya. Pane kudaro, hunhu hwavo hukuru kuoma, izvo zvinovapa kuramba kupisa nekupfeka, kuramba kupfeka nguva isati yakwana izvo zvinogona kukanganisa kupera kwezvikamu zvakachekwa. . TCT blades dzinodhura zvakanyanya asiwo dzakanyanya kuoma uye dzinokwanisa kushanda patembiricha yakatokwira kupfuura HSS. Izvi zvinobvumira TCT saw blades kuti ishande pamwero wakakurumidza kupfuura HSS blades, ichideredza zvakanyanya nguva yekucheka.

Zvakanakira Kushandisa Cold Saw

Cold masaha anogona kushandiswa kucheka akawanda akasiyana maumbirwo, kusanganisira tsvimbo, machubhu, uye extrusions. Otomatiki, akavharirwa denderedzwa inotonhora masaha anoshanda nemazvo pakugadzira kumhanya uye anodzokorora mapurojekiti uko kushivirira uye kupera kwakakosha. Michina iyi inopa inochinja-chinja blade kumhanya uye inochinjika mareti ekudya epamusoro-kumhanya kugadzirwa uye burr-yemahara, kucheka kwakaringana.

Masaha anotonhora, ane mazino awo, anoita kucheka kwakachena pasina mabheti. Nepo mablades abrasive anowanzo kudzungaira, kunyangwe pakucheka kwakatwasuka, mazino ane mazino anonyanya kuvimbika pakucheka kwakatwasuka kana kukona. Nechipanga chakanaka, chakapinza, saha inokurumidza denderedzwa inotonhora ine zvakanakira zvekupotsa kubvisa maburrs uye kusaburitsa sparks, discoloration, kana huruva. Saka, iyo nzira inowanzopa kupedzisa kwemhando yepamusoro ine mipendero yechokwadi.Idzo zvakare dzakanyanya kushomeka pasina iyo yose iyo abrasive huruva inowana pane zvese munzvimbo yayo.

Iyo inotonhora sawing process inokwanisa kupinza zvakanyanya pamasimbi akakura uye anorema - mune mamwe mamiriro, kunyange akasimba se ± 0.005 ”(0.127 mm) kushivirira. Masaha anotonhora anogona kushandiswa kucheka simbi dzese dzine ferrous uye dzisiri-ferrous, uye kune ese ari maviri akakatwa uye angled kucheka.

Unogona kuchengetedza mari nesaha inotonhora

Kunyange zvazvo mutengo wekutanga weshizha rinotonhora ungave wakakwira kupfuura dhisiki rinoputika, unogona kurodzazve blade-inopinza blade kakawanda, ichidudzira mukuchengetedza kwakakosha. Masaha anotonhora anochengetedzawo nguva nemari nekucheka chaiko.

Aya machekwa asina kukanganisa haadi yechipiri kupedzisa oparesheni, kuchengetedza basa rakawanda muzviitiko zvakawanda. Kuchekwa chaiko kuchiri chimwe chikomborero sezvo inotonhora yekucheka masaha inogona kubata kushivirira padyo, zvakare kubvisa inodhura yechipiri saizi yekushanda.

Kutonhora kwesaha isarudzo yakanaka kune yako simbi cutoff application?

Usati wasarudza inotonhora sawing kune yako simbi chikamu cutoff, zvakakosha kuti unzwisise zvakanakira nekuipira kwekuita. Nenzira iyo, iwe unogona kuongorora uye kusarudza kana iyo - kana chero imwe nzira chaiyo yekucheka simbi yaungave uchifunga - ichazadzisa zvaunoda uye zvaunokoshesa.

Zvakaipa Kushandisa Cold Saw

Zvisinei, kutonhora kunotonhora hakuna kunaka kune hurefu huri pasi pe 0.125 "(3.175 mm). Uyezve, nzira yacho inogona kubudisa mabhero anorema. Kunyanya, inyaya iyo iwe une maODs pasi pe0.125 "(3.175 mm) uye pane maID maduku zvikuru, apo chubhu yaizovharwa neburr inogadzirwa nechando.

Chimwe chinodzikira kumasaha anotonhora ndechekuti kuomarara kunoita kuti masaha ave brittle uye anogona kuvhunduka. Chero huwandu hwekudengenyeka - semuenzaniso, kubva pakusakwana kusungirirwa kwechikamu kana chiyero chisiri chekudya - chinogona kukuvadza nyore mazino esaha. Pamusoro pezvo, masaha anotonhora anowanzo kukonzeresa kurasikirwa kwekefi, izvo zvinoshandura mukurasikirwa kwekugadzirwa uye kudhura kwakanyanya.

Kunyange zvazvo kutonhora kwekucheka kunogona kushandiswa kucheka alloys akawanda ane ferrous uye asina-ferrous, hazvikurudzirwi kune simbi dzakaoma zvikuru - kunyanya, iyo yakaoma kudarika saw pachayo. Uye nepo masaha anotonhora achigona kucheka mabundled, anogona chete kuzviita nediki dhayamita zvikamu uye yakakosha kugadzirisa kunodiwa.

Akajairika iron yekucheka masaha blades:

1. Kucheka michina: Nguva dzose simbi yekucheka saw blades, kune rumwe rutivi, inowanzoshandisa abrasive kana high-speed simbi mazino kutema simbi. Aya mashizha anobudisa kupisa kwakawanda panguva yekucheka, izvo zvinogona kukonzera burrs uye thermal deformation ye workpiece.

2. Material kugarisana: Nguva dzose simbi yekucheka saw blades yakakodzera kucheka simbi yakapfava sesimbi yakapfava, simbi yakakandwa uye zvimwe zvinhu zvakafanana. Aya mablades anowanzo shandiswa mune zvakajairika kugadzira uye kuvaka zvikumbiro uko kuchekwa chaiko hakusi kunetseka kukuru.

3. Blade hupenyu: Nguva dzose simbi yekucheka saw blades inogona kukurumidza kupfeka nekuda kwekupisa kwakanyanya kunogadzirwa panguva yekucheka. Naizvozvo, dzingangoda kutsiviwa kakawanda, kunyanya kana dzichishandiswa mabasa anorema-basa rekucheka.

4. Kucheka kukurumidza uye kushanda zvakanaka: General iron cutting saw blades inozivikanwa nokuda kwekumhanya kwayo kukuru, zvichiita kuti dzive dzakakodzera kukurumidza, kucheka kwekucheka mumatare ane ferrous. Zvisinei, kupisa kunogadzirwa panguva yekucheka kunogona kukanganisa kunaka kwekucheka uye kuwedzera kupedzisa kunogona kudiwa kuti uwane chigumisiro chinodiwa.

mukupedzisa:

Muchidimbu, sarudzo pakati peanotonhora esaha blades uye akajairwa simbi yekucheka masaha blades zvinoenderana nezvinodiwa chaizvo zvesimbi yekucheka application. Cold saw blades akanyanya kuchekwa kwepamusoro-soro kwesimbi isina-ferrous, inopa yakachena, isina-burr-yekucheka uye kuwedzera hupenyu hweblade. Nguva dzose simbi yekucheka saw blades, kune rumwe rutivi, yakanakira kukurumidza, kuchekwa kwakakasharara mumasimbi ane ferrous, kunyangwe ingangoda mamwe maitiro ekupedzisa. Kunzwisisa mutsauko uripo pakati pemhando mbiri idzi dzemasaha kwakakosha pakusarudza sarudzo yakakodzera pane yakapihwa simbi yekucheka basa.

Tarisa denderedzwa inotonhora saha kana basa rako:

-

Inocheka zvinhu izvo kazhinji zvisina kunyanyokura -

Inoita yakawanda miter yekucheka -

Inofanirwa kuburitsa mapeji akachena ayo asingade echipiri maoperation -

Zvinoda kudzivirira kupisa zvinhu kana kugadzira maburrs pamakona akachekwa -

Anoda kubhadhara zvakanyanya, asi gamuchira yakakwira ROI

Rangarira, aya masaha blade imari yenguva refu. Funga zvaunoda zvazvino uye zveramangwana paunenge uchiita sarudzo. Iyo saha yerudyi inosimudzira yako purofiti uye kugona kwemakore.

Kuti uwane zvimwe,zadza fomu redu rekuonana,kanaemail us.

Nguva yekutumira: Sep-14-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Kurova Saw Blade

HERO Kurova Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminium Saw

HERO Aluminium Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Kukura Saw Blade

PCD Kukura Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Saw

PCD Aluminium Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw yeSimbi

Cold Saw yeSimbi Cold Saw Blade yeFerrous Metal

Cold Saw Blade yeFerrous Metal Dry Cut Saw Blade yeFerrous Metal

Dry Cut Saw Blade yeFerrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Kuburikidza neDrill Bits

Kuburikidza neDrill Bits Hinge Drill Bits

Hinge Drill Bits TCT Nhanho Drill Bits

TCT Nhanho Drill Bits HSS Drill Bits / Mortise Bits

HSS Drill Bits / Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Kurebesa Straight Bits

Kurebesa Straight Bits TCT Yakarurama Bits

TCT Yakarurama Bits M16 Yakananga Bits

M16 Yakananga Bits TCT X Yakananga Bits

TCT X Yakananga Bits 45 Dhigirii Chamfer Bit

45 Dhigirii Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Zvishandiso

Edge Banding Zvishandiso TCT Yakanaka Kucheka Cutter

TCT Yakanaka Kucheka Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Yakanaka Kucheka Cutter

PCD Yakanaka Kucheka Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Zvimwe Zvishandiso & Zvishandiso

Zvimwe Zvishandiso & Zvishandiso Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives