Dambudziko nderopi nemaedge banding?

Edgebanding inoreva zvese maitiro uye tambo yemidziyo inoshandiswa kugadzira inoyevedza inoyevedza trim yakatenderedza isina kupera mipendero yeplywood, particle board, kana MDF. Edgebanding inowedzera kusimba kweakasiyana mapurojekiti senge cabinetry uye countertops, ichivapa iyo yepamusoro-yekupedzisira, yemhando yemhando.

Edgebanding inoda kushandiswa kwakasiyana-siyana maererano neadhesive application. Kupisa kwekamuri, pamwe chete ne substrate, kunokanganisa kunamatira. Sezvo edgebanding ichigadzirwa kubva kune akawanda akasiyana zvinhu, zvakakosha kuti usarudze adhesive inopa hunyanzvi uye kugona kwekugona kusungirira kune akasiyana substrates.

Hot melt glue inonamira ine-zvinangwa yakawanda inoshandiswa mune dzakasiyana siyana maapplication uye inokodzera kune yakaringana ese mabhendi ekumucheto anosanganisira PVC, melamine, ABS, acrylic uye huni veneer. Kupisa kunyunguduka isarudzo huru nokuti inokwanisika, inogona kudzokororwa zvakare, uye iri nyore kushanda nayo.Chimwe chezvakaipa zvehot melt adhesive edge sealing ndeyokuti kune glue seams.

Zvisinei, kana glue seams ari pachena, zvingave kuti midziyo haina kugadziriswa zvakanaka. Kune zvikamu zvitatu zvikuru: pre-milling cutter part, rubber roller unit uye pressure roller unit.

1. Kusagadzikana mune pre-milling cutter chikamu

-

Kana hwaro hwepamusoro hwebhodhi rakagadzirwa-kare rine mitsetse uye glue rinoshandiswa zvisina kuenzana, zvirema zvakadai semitsetse yakanyanyisa yeglue ichaitika.Nzira yekutarisa kana pre-milling cutter yakajairika ndeyekudzima mayuniti ese uye kungobatidza chete pre-milling cutter. Mushure mekufanogaya MDF, tarisa kana nzvimbo yebhodhi yakati sandara. -

Kana pre-milled ndiro isina kuenzana, mhinduro ndeyekuitsiva neinocheka-pre-milling cutter.

2. Rubber roller unit haina kujairika.

-

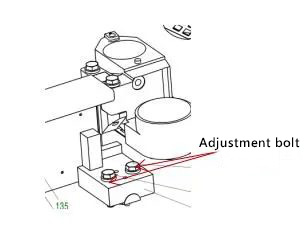

Panogona kunge paine chikanganiso mu perpendicularity pakati perubber coating roller uye base base yeplate. Iwe unogona kushandisa sikweya mutongi kuyera iyo perpendicularity. -

Kana kukanganisa kwakakura kudarika 0.05mm, zvinokurudzirwa kutsiva zvose zvigayo zvekucheka.Apo iyo glue yekuputira dziva iri pasi pekupisa kwemaindasitiri, kutonhora kunosvika 180 ° C uye haigoni kubatwa nemaoko asina maoko. Nzira iri nyore yekutarisa ndeyekutsvaga chidimbu cheMDF, gadzirisa huwandu hweglue kune hushoma, uye ona kana iyo yakanamatira magumo kumusoro uye pasi. Ita zvigadziriswe zvishoma nekugadzirisa mabhoti kuitira kuti chiso chese chekupedzisira chigone kushandiswa zvakaenzana nehuwandu hushoma hweglue.

3. Iyo yekumanikidza vhiri unit haina kujairika

-

Pane zvakasara zveglue mamaki pamusoro pevhiri rekumanikidza, uye kumusoro hakuna kuenzana, izvo zvinokonzeresa kusasimba kwekudzvanya. Inoda kucheneswa nekufamba kwenguva, wobva watarisa kana kudzvanywa kwemhepo uye vhiri rekumanikidza zvakajairika. -

Zvikanganiso mu verticality yevhiri rekutsikirira zvinozotungamira kune kushata kumucheto chisimbiso. Nekudaro, iwe unofanirwa kutanga wasimbisa kuti hwaro hwepamusoro hwebhodhi hwakatsetseka usati wagadzirisa verticality yevhiri rekutsikisa.

Zvimwe zvinowanzoitika zvinokanganisa kunaka kwekumucheto banding

1, Equipment Dambudziko

Nekuti injini yemupendero bhendi muchina uye track haigone kubatirana zvakanaka, iyo track haina kugadzikana panguva yekushanda, ipapo kumucheto banding mitsetse haikodzeri kumucheto zvakakwana. kushayikwa kweglue kana kupfekedzwa kusina kuenzana kunowanzokonzerwa negluing pressure rod isingabatanidzi zvakanaka ne conveyor chain pad. Kana maturusi ekuchekeresa uye maturusi echamfering zvisina kugadziridzwa zvakanaka, kwete chete zvinoda kuwedzera kushanda kwekushanda, uye kunaka kwekucheka kwakaoma kuvimbisa.

Muchidimbu, nekuda kweiyo yakashata nhanho yekutumwa kwemidziyo, kugadzirisa uye kugadzirisa, matambudziko emhando achagara. Iyo blunt yezvishandiso zvekucheka inobatawo zvakananga kunaka kwemagumo uye kucheka. Kona yekuchekeresa yakapihwa nemidziyo iri pakati pe0 ~ 30 °, uye kona yekucheka yakasarudzwa mukugadzirwa kwakawanda i20 °. Iyo blunt blade yechishandiso chekucheka ichaita kuti kunaka kwepamusoro kuderera.

2, The Workpiece

Muti wakagadzirwa nemunhu sechinhu che workpiece, kutsauka kwehupamhi uye flatness inogona kunge isingasviki zviyero. Izvi zvinoita kuti chinhambwe kubva pakumanikidzwa roller mavhiri kusvika pamusoro peconveyor yakaoma kuseta. Kana chinhambwe chakanyanya kudiki, chinokonzeresa kudzvanywa uye kuparadzanisa mitsetse uye workpiece. Kana kureba kwakanyanyisa, ndiro haigoni kuomeswa, uye mitsetse haigoni kusungirirwa zvakasimba nemucheto.

3, Edge Banding Strips

Iwo emupendero banding mitsetse inonyanya kugadzirwa nePVC, iyo inogona kukanganiswa zvakanyanya nenharaunda. Munguva yechando, kuoma kwePVC mitsetse kuchawedzera izvo zvinokonzera kunamatira kweglue kunoderera. Uye iyo yakareba nguva yekuchengetedza, nzvimbo ichakwegura; simba rekunamatira kune glue rakaderera. Pamapepa akaitwa mitsetse ine gobvu diki, nekuda kwekusimba kwayo uye kushomeka kwadzo (senge 0.3mm), zvinokonzeresa kuchekwa kusina kuenzana, kusakwana kwesimba rekubatanidza, uye kushomeka kwekucheka. Saka matambudziko akadai sekurasa hombe kwema edge banding strips uye high rework rate zvakakomba.

4, Kamuri Tembiricha uye Machine Tembiricha

Kana tembiricha yemukati yakadzikira, iyo workpiece inopfuura nepamucheto banding muchina, tembiricha yaro haigone kuwedzera nekukurumidza, uye panguva imwe chete, iyo yekunamatira inotonhorera nekukurumidza izvo zvakaoma kupedzisa kubatana. Nokudaro, kutonhora kwemukati kunofanira kudzorwa pamusoro pe15 ° C. Kana zvichidikanwa, zvikamu zvemupendero bhandi yemushini inogona kupiswa isati yashanda (iyo heater yemagetsi inogona kuwedzerwa pakutanga kwekumucheto banding process). Panguva imwecheteyo, tembiricha yekudziya yekuratidzira yegluing pressure tsvimbo inofanirwa kuenzana kana kukwira kupfuura tembiricha iyo inopisa inonyungudika yakanamatira inogona kunyungudika zvachose.

5,Kudyisa kukurumidza

Iyo yekumhanyisa yekudyisa yemazuva ano otomatiki edge mabhenji emuchina anowanzo 18 ~ 32m / min. Mimwe michina inomhanya-mhanya inogona kusvika 40m/min kana kukwira, ukuwo manyorero curve edge banding muchina une spidhi yekudyisa ye4 ~ 9m/min chete. Iyo yekudyisa kumhanya yeatomatiki edge banding muchina inogona kugadziridzwa zvinoenderana nemupendero banding simba. Kana kukurumidza kwekudya kwakanyanyisa, kunyange zvazvo kubudirira kwekugadzira kwakakwirira, simba remabhenji rekumucheto rakaderera.

Ibasa redu kupinza bhendi nemazvo. Asi iwe unofanirwa kuziva, pachine sarudzo dzauchazoda kuita kana uchiongorora edge banding sarudzo.

Sei uchisarudza HERO pre-milling cutter?

-

Inogona kugadzirisa zvinhu zvakasiyana-siyana. Iwo makuru ekugadzirisa zvinhu ndeye density board, particle board, multilayer plywood, fiberboard, nezvimwe. -

Iyo blade inogadzirwa nedhaimondi zvinhu kunze kwenyika, uye kune chitarisiko chakakwana chedhizaini yezino chaizvo. -

Yakazvimirira uye yakanaka package ine katoni uye sponge mukati, iyo inogona kudzivirira panguva yekufambisa. -

Iyo inonyatsogadzirisa kukanganisa kweasina kusimba uye yakakomba kupfeka kwecarbide cutter. Inogona kuvandudza zvakanyanya kunaka kwekuonekwa kwechigadzirwa. Ipa hupenyu hurefu hwekushandisa. -

Hapana kusviba, hapana kupatsanurwa kwemupendero, kutaridzika kwakakwana kwekugadzira mazino, kuenderana nehunyanzvi hwekugadzira. -

Isu tine anopfuura makore makumi maviri echiitiko uye tinopa yakakwana pre-kutengesa uye mushure-yekutengesa masevhisi. -

Yakanakisa yekucheka mhando muhuni-yakavakirwa zvinhu zvine fiber.

Nguva yekutumira: Mar-01-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Kurova Saw Blade

HERO Kurova Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminium Saw

HERO Aluminium Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Kukura Saw Blade

PCD Kukura Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Saw

PCD Aluminium Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw yeSimbi

Cold Saw yeSimbi Cold Saw Blade yeFerrous Metal

Cold Saw Blade yeFerrous Metal Dry Cut Saw Blade yeFerrous Metal

Dry Cut Saw Blade yeFerrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Kuburikidza neDrill Bits

Kuburikidza neDrill Bits Hinge Drill Bits

Hinge Drill Bits TCT Nhanho Drill Bits

TCT Nhanho Drill Bits HSS Drill Bits / Mortise Bits

HSS Drill Bits / Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Kurebesa Straight Bits

Kurebesa Straight Bits TCT Yakarurama Bits

TCT Yakarurama Bits M16 Yakananga Bits

M16 Yakananga Bits TCT X Yakananga Bits

TCT X Yakananga Bits 45 Dhigirii Chamfer Bit

45 Dhigirii Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Zvishandiso

Edge Banding Zvishandiso TCT Yakanaka Kucheka Cutter

TCT Yakanaka Kucheka Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Yakanaka Kucheka Cutter

PCD Yakanaka Kucheka Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Zvimwe Zvishandiso & Zvishandiso

Zvimwe Zvishandiso & Zvishandiso Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives