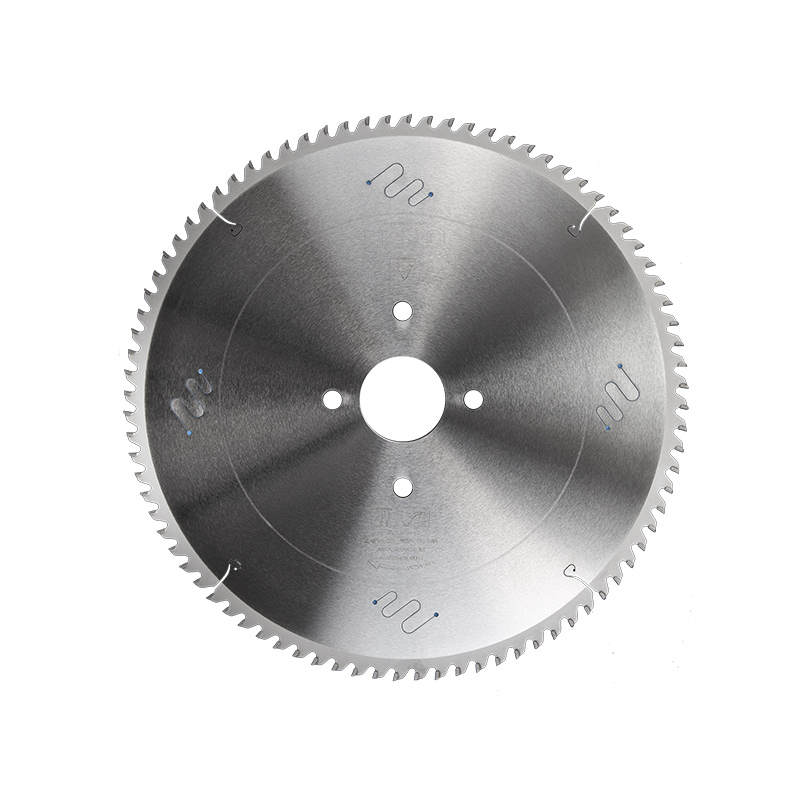

PCD Saw Blade for Panel Cabbirka Saw Blade

Dulmarka alaabta

Alaabta ceeriin:Qaybta PCD, Jarmal laga keenay saxan bir ah 75CR1 iyo Japan oo soo dejisay saxan bir ah SKS51.

Summada:GEESI, LILT

Astaamaha

1. Waxaa loo isticmaalaa in lagu gooyo saqafyada alwaaxda iyo in lagu bixiyo miinshaar dheeraad ah oo lagu gooyo looxa walxaha, MDF, iyo looxa melamine.

2. Waxaa loo adeegsaday qalab kala duwan, sida Biesse, Homag, iyo miinshaar alwaax ah.

Faa'iidada:

1. Naqshad aamusnaan leh oo Japan ku qoyan iyo daahan chrome ah oo loogu talagalay goynta iyada oo aan buuq lahayn.

2. Qaybta PCD waxay ballan qaaday inay kordhinayso cimriga qalabka iyo daabadaha.

3. Naqshadaynta ka-hortagga gariirku waxay yaraynaysaa gariirka waxayna kor u qaadaysaa waxqabadka, ka hortagga jajabinta iyo dhamaystirka goynta.

4. Nidaamyo adag oo hubinaya in bacaha miinshaaruhu ay yihiin kuwo heer sare ah, kordhiya wax soo saarka, yaraynta wakhtiga loo baahan yahay beddelka, iyo dhimista kharashka qalabka.

5. Isticmaalka mashiinada Gerling si aad u dhamaystirto habka brazing iyo sandwich silver-copper-teknoolajiyada silver-copper si loo xoojiyo ilkaha.

Iftiimin:

● 1. Ilaali kontoroolka heerkulka adag inta aad ka shaqaynayso qaybta PCD.

2. Si aad u dhammaystirto habka wax-shiidida, oo ah tallaabada ugu muhiimsan ee miinshaarta PCD, isticmaal giraangiraha korantada ee naxaasta ah.

3. Dhererka caadiga ah ee ilig PCD waa 6.0mm, waxaa loo habeyn karaa iyadoo loo eegayo shuruudo gaar ah, tusaale ahaan 6.8mm iyo 7mm. Inta ka sii badan qaybta PCD-ga ayaa sii kordhaysa nolosha.

● 4. Faa'iidada ugu weyn waa nolosha qalabyada oo dheer, oo ku saabsan 50 jeer in ka badan TCT carbide tipped miinshaar. Tusaale ahaan waxaad ku kharash garaysaa 5 jeer lacag ka badan si aad u hesho badeeco shaqaynaysa 50 jeer ka dheer, waxaadna sii wadi kartaa shaqada 30 maalmood adiga oo hal mar ka bedelaya mishiinka, kaas oo sidoo kale kaa badbaadiya wakhti badan oo aad ku beddesho garbaha. Maxay noqon lahayd doorashadaadu?

Halbeegyada

1. Alaabtan waxaa sida caadiga ah loo soo saaray in lagu gooyo galka alwaaxyada, qayb ka mid ah, dahaaran iyo MDF ee miinshaar miiska iyo muraayadaha cabbirka.

2. Is barbar dhig kaarbiid tungsten iyo birta miinshaar wareeg ah, daab pcd miinshaar waa adag tahay oo si weyn u waara, fulinta 30-50 jeer ka dheer nolosha qalab, iyo tani waxay badbaadisaa labadaba waqti iyo lacag.

3. Mashiinada: miinshaar labajibbaaran, miinshaar guddi, miinshaar la jaray iyo mashiinnada kale ee CNC iwm.

4. Codsiga: aad u sax ah oo loogu talagalay 45 darajo iyo 90 goynta wadajirka ah. Gaar ahaan waxaa lagu soo dhaweeyay daaqadaha aluminium ama albaabbada soo saarayaasha.

| OD (mm) | Bore | Dhumucda Kerf | Dhumucda saxanka | Tirada Ilkaha | Shiidi |

| 350 | 30 | 4.4 | 3.2 | 72 | TCG |

| 350 | 30 | 4.4 | 3.2 | 84 | TCG |

| 380 | 60 | 4.4 | 3.2 | 72 | TCG |

| 380 | 60 | 4.4 | 3.2 | 84 | TCG |

| 380 | 60 | 4.4 | 3.2 | 96 | TCG |

| 400 | 60 | 4.4 | 3.2 | 72 | TCG |

| 400 | 60 | 4.4 | 3.2 | 84 | TCG |

| 400 | 75 | 4.4 | 3.2 | 84 | TCG |

| 400 | 60 | 4.4 | 3.2 | 96 | TCG |

| 450 | 60 | 4.4 | 3.2 | 72 | TCG |

| 450 | 60 | 4.8 | 3.5 | 84 | TCG |

| 450 | 60 | 4.8 | 3.5 | 96 | TCG |

TCT Saw Blade

TCT Saw Blade Halyeeyga Cabirka arka Blade

Halyeeyga Cabirka arka Blade Hero Panel Cabbirka Sawirka

Hero Panel Cabbirka Sawirka Halyeeyga Dhibcaha Saw Blade

Halyeeyga Dhibcaha Saw Blade HERO Adag alwaax arka Blade

HERO Adag alwaax arka Blade HERO Aluminium Saw

HERO Aluminium Saw Grooving saw

Grooving saw Sawirka Muuqaalka Birta

Sawirka Muuqaalka Birta Edge Bander arkay

Edge Bander arkay Akrilik saw

Akrilik saw PCD Saw Blade

PCD Saw Blade PCD Cabbirka Saw Blade

PCD Cabbirka Saw Blade PCD Panel Cabbirka Sawirka

PCD Panel Cabbirka Sawirka Dhibcaha PCD Saw Blade

Dhibcaha PCD Saw Blade PCD Grooving saw

PCD Grooving saw PCD Aluminium Saw

PCD Aluminium Saw Qabow miinshaar birta ah

Qabow miinshaar birta ah Daabka Qabow ee Birta Ferrous

Daabka Qabow ee Birta Ferrous Daabka miinshaar ee qallalan ee birta birta ah

Daabka miinshaar ee qallalan ee birta birta ah Mashiinka arka qabow

Mashiinka arka qabow Qodista

Qodista Dowel Drill Bits

Dowel Drill Bits Iyada oo loo marayo Qodista

Iyada oo loo marayo Qodista Hinge Drill Bits

Hinge Drill Bits TCT Talaabada Qodista

TCT Talaabada Qodista HSS Drill Bits/ Dhimashada Dhirta

HSS Drill Bits/ Dhimashada Dhirta Router Bits

Router Bits Qoto toosan

Qoto toosan Qoto dheer oo toosan

Qoto dheer oo toosan TCT toosan

TCT toosan M16 Qoddobo toosan

M16 Qoddobo toosan TCT X Bits toosan

TCT X Bits toosan 45 Degree Chamfer Bit

45 Degree Chamfer Bit Xarigga Bit

Xarigga Bit Wareegga Geeska Bit

Wareegga Geeska Bit PCD Router Bits

PCD Router Bits Aaladaha Banding Edge

Aaladaha Banding Edge Gooyaha Wanaagsan ee TCT

Gooyaha Wanaagsan ee TCT TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander arkay

Edge Bander arkay PCD Fine jar jaritaanka

PCD Fine jar jaritaanka PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Qalab Kale & Agabka

Qalab Kale & Agabka Qalabka Qalabaynta

Qalabka Qalabaynta Qodista Chucks

Qodista Chucks dheeman ciid Wheel

dheeman ciid Wheel Midiyaha Qorsheeyaha

Midiyaha Qorsheeyaha