Ngaba iMetal inokusikwa ngesarha yesarha?

Yintoni i-Miter Saw?

Isarha yemiter okanye isarha yonkontsho yisarha esetyenziselwa ukwenza ii-crosscuts ezichanekileyo kunye neemitha kwindawo yokusebenza ngokubeka iblade egxunyekiweyo ebhodini. Isarha yesarha ekwimo yayo yokuqala yenziwe ngesarha engasemva ekwibhokisi yonkontsho, kodwa kumiliselo lwangoku iquka isarha esetyhula enamandla enokubekwa kwii-engile ezahlukeneyo ize ithotywe ebhodini emiswe kufutshane nomqolo obizwa ngokuba lucingo.

I-Miter Saw isetyenziselwa ntoni?

Isarha yokulinganisa luhlobo lwesarha emileyo eyilelwe ukwenza ukuchaneka kokusikeka kwii-engile ezininzi. I-blade itsalwa ezantsi kwizinto eziphathekayo, ngokungafaniyo nesarha yesetyhula apho isondla khona ngezinto.

Iisarha zeMiter zezona zilungele ukusika iibhodi ezinde ngenxa yobuchule bazo obukhulu bokusika. Usetyenziso oluqhelekileyo lwesarha yonkontsho lubandakanya ukusikwa kwemiter ngokukhawuleza nangokuchanekileyo (okufana nee-engile ezingama-45 zokwenza iifreyimu zemifanekiso) okanye ukwenza usiko lokunqunqa umnqamlezo, ukusika imitha, ukusikwa kwe-bevel nokunye konke ngesi sixhobo sinye sisebenza ngeendlela ezininzi.

Iisarha zomgama ziza ngobukhulu obahlukeneyo. Ubungakanani be-blade bumisela amandla okusika i-saw. Ubukhulu bomthamo ofunekayo wokusika, ubukhulu besarha kufuneka ukhethe.

Iindidi zeesarha zeMiter

Iisarha zokulinganisa zingahlulwa zibe ziindidi ezintathu ezincinci ngokusekelwe kwimisebenzi ethile enxulumene nodidi ngalunye lwesarha. Ezi ntlobo zintathu zibandakanya isarha yokulinganisa esemgangathweni, isarha ehlanganisiweyo yesarha, kunye nesarha edibeneyo yokutyibilika.

I-bevel enye:Unokwenza ukusikwa kwe-miter kunye nokusika kwe-bevel kwicala elinye.

I-bevel kabini: Inokwenza ukusikwa kwe-bevel kumacala omabini. Iisarha eziphindwe kabini ze-bevel miter zingcono xa ufuna ukusika ii-engile ezininzi njengoko zigcina ixesha ekutshintsheni icala lemathiriyeli.

Isarha yokudibanisa i-miter:I-miter edibeneyo yindibaniselwano ye-miter kunye ne-bevel cut. I-miter yenziwe ngokujikeleza isiseko somatshini phakathi kwentsimbi yesi-8 kunye neye-4. Nangona inani lomlingo lemitres libonakala lingama-45°, iisarha ezininzi zemiter ziyakwazi ukusika iiengile ukuya kuma-60°. Ukusikwa kweBevel kwenziwa ngokuthambeka iblade ukusuka kwi-90° ngokuthe nkqo ukuya kutsho kubuncinci be-45°, kwaye kaninzi ukuya kuma-48°– kubandakanywa zonke ii-engile phakathi.

Ukukwazi ukwenza i-miter edibeneyo yokusika ifanelekile kwizicelo ezinjengokusika ukubumba isithsaba, okanye ukusebenza kwiiprojekthi ezifana nokuguqulwa kwe-loft, apho ii-engile zeendonga kunye neepatshi zesilingi kufuneka ziqwalaselwe. Apha kulapho ii-engile ezingaqhelekanga ze-31.6° kunye ne-33.9° eziboniswe kwiigeyiji zezinye iisarha zombhobho wemitha ziqala ukudlala.

Isarha yonkontsho edibeneyo yokutyibilika:Isarha yenkomponi etyibilikayo inokwenza umnqwazi ofanayo, i-bevel kunye ne-compound cuts njengesarha ehlanganisiweyo engatyibilikiyo, enophawu olunye olongezelelweyo. Umsebenzi wokutyibilika wonyusa umthamo wokusika ububanzi ngokuvumela iyunithi yemoto kunye neblade encanyathiselweyo ukuba ihambe ngeentonga zetelescopic.

Njengoko iisarha zombhobho weslayidi ezidityanisiweyo zixhomekeke ekuphatheni, indlela yokutyibiliza yindlela ekrelekrele yokunikezela ngamanxeba abanzi kakhulu, ngeli lixa umatshini ubambene ngokuthe ngqo.

Ngaba unokuyisika iMetal ngeSaw yeMiter?

Isarha yeMiter ngoyena mhlobo usenyongweni womchweli onikwe indlela eguquguquka ngayo kwaye eluncedo ngayo, kodwa ngaba ungayisika intsimbi ngesarha yemitha?

Ngokubanzi, ukuxinana kunye nokuqina kwemathiriyeli yesinyithi akukho nzima kakhulu ukuba ingaphathwa yinjini yesarha. Nangona kunjalo, kukho imiba ethile ekufuneka uyiqaphele phambi kokuba ukhawuleze ukungena. Okokuqala, iseti yeblade yesarha ayiwufanelanga ngokufanelekileyo lo msebenzi, ngoko ke inyathelo lokuqala kukufumana indawo efanelekileyo. Nceda uqaphele ukuba kukho amanyathelo okhuseleko ekufuneka uwaqaphele nawo.

Yeyiphi iBlade onokuthi uyisebenzise xa ugawula isinyithi?

Ngokuqinisekileyo, i-miter yakho ye-saw blade iya kwenza umsebenzi omangalisayo wokusika iinkuni kunye nokusika iitrim, nangona kunjalo, ukusebenza ngesinyithi usebenzisa uhlobo olufanayo lwe-blade luchaza intlekele. Kambe ke, loo nto ayifanelanga isothuse njengoko iincakuba ezinje ziyilwe kucingwa ngokugawula iinkuni. Nangona ezinye iisarha zemiter zinokulungela iintsimbi ezingezizo i-ferrous (ezifana notshintsho oluthambileyo lukagoogle okanye ubhedu) – ayikhuthazwa njengesisombululo esisisigxina. Ukuba usebenza kwiprojekthi enokufuna ukusika ngokukhawuleza kunye nokuchanekileyo kwisinyithi kodwa ungenayo isixhobo esingcono sokunikela, emva koko ukutshintshela ama-carbide blades akho ngenye indlela isisombululo esilula. Iindaba ezimnandi zezokuba kukho intaphane yeencakuba zokusika isinyithi ezikumgangatho ophezulu ezikhoyoIQHAWE, ngoko ukufumana into efanelekileyo akuyi kuba nzima kakhulu. Qiniseka nje ukuba ukhetha uhlobo olufanelekileyo ngokuxhomekeke kuhlobo lokusikeka oza kulwenza

Kwenzeka ntoni xa ungatshintshi iBlade kwaye Uyinqumle kwiMetal?

Ukuba uthatha isigqibo sokuba awukwazi ukukhathazeka ngengxaki kwaye unqwenela ukuzama inhlanhla yakho ngokusika isinyithi usebenzisa i-miter saw kunye ne-blade yayo ekhoyo, nantsi into eyenzekayo:

-

Iisarha zeMiter zisebenza ngesantya esingaphezulu kunokuba zifuna isinyithi-oku kukhokelela kwingxabano enkulu phakathi komphezulu wokusika kunye neblade ngokwayo. -

Oku kuya kuthi emva koko kukhokelele kuzo zombini isixhobo kunye nomsebenzi-ukufudumeza ngokubalulekileyo okunokuba nefuthe elibi kwisakhiwo sesinyithi. -

Izixhobo ezishushu ezivuthayo kunye nezixhobo ziya kukubeka wena kunye nendawo yakho yokusebenzela kumngcipheko omkhulu womonakalo kunye / okanye ukwenzakala

Ngaba kufuneka usebenzise i-miter saw ukusika kwisinyithi?

Kungenxa yokuba ungasebenzisa i-miter saw ukusika ingqondo ayithethi ukuba kufuneka ibe sisisombululo sakho esisisigxina. Inyaniso kukuba, ukutshintsha i-miter saw blades yokusika isinyithi akuyona indlela ebiza kakhulu njengoko baya kufuna ukutshintshwa. Kwakhona, i-RPM ye-miter saw iphezulu kakhulu kunemfuneko yokusika isinyithi. Oku kuya kubangela kuphela iintlantsi ezininzi eziphaphazela ngapha nangapha kunokuba kuyimfuneko. Ukongeza, ngokusetyenziswa ngokugqithisileyo kunye nokufudumeza okuqhelekileyo, i-miter saw motor inokuqalisa ubunzima. Unokusebenzisa isarha yakho yokusikwa ngokuphindaphindiweyo ukusika isinyithi ukuba usebenza kwiiprojekthi ezingafuneki rhoqo ukusikwa kwintsimbi. Nangona kunjalo, ukuba ukusika isinyithi yinto ekuya kufuneka uyenzile rhoqo, zifumanele isixhobo sokusika isinyithi, umzekelo:

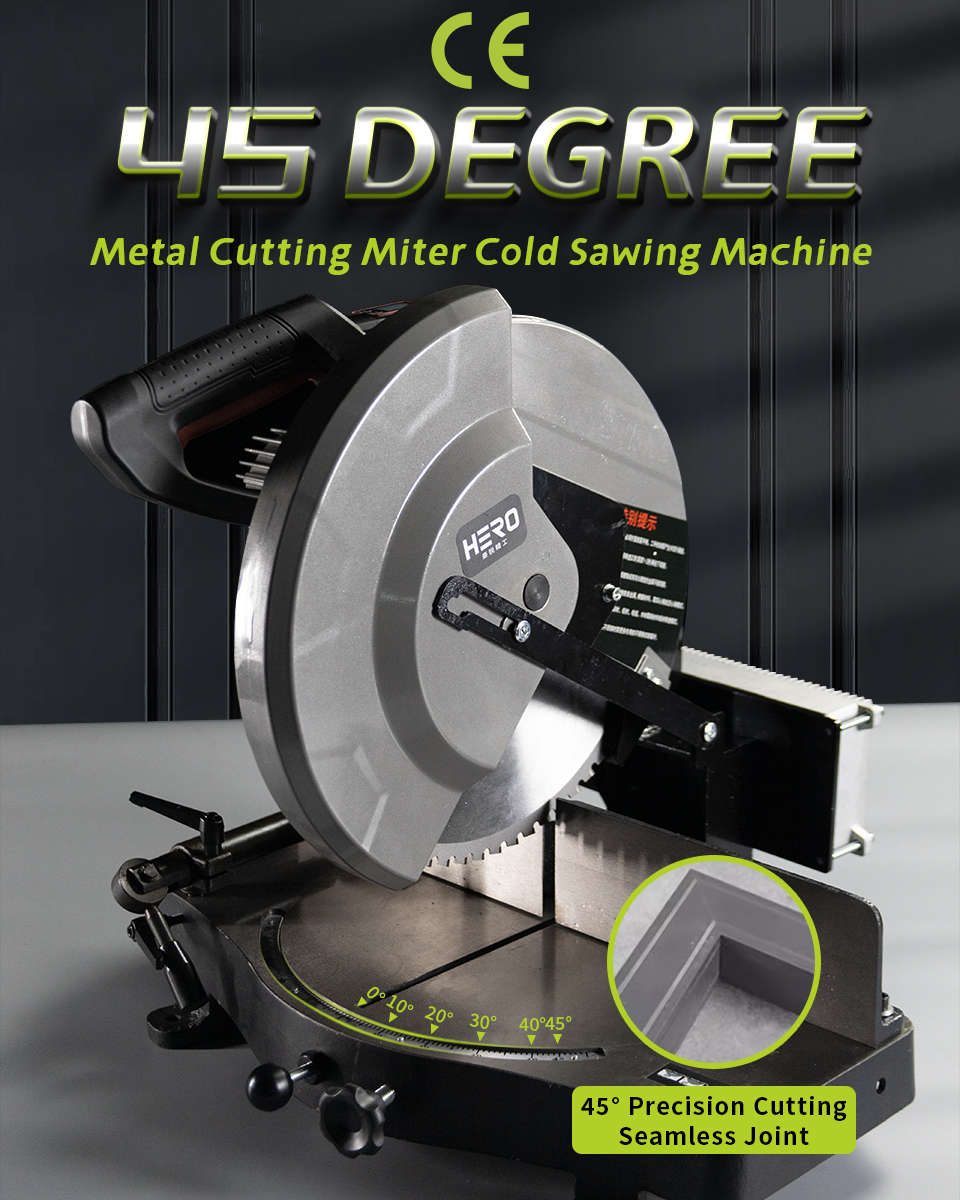

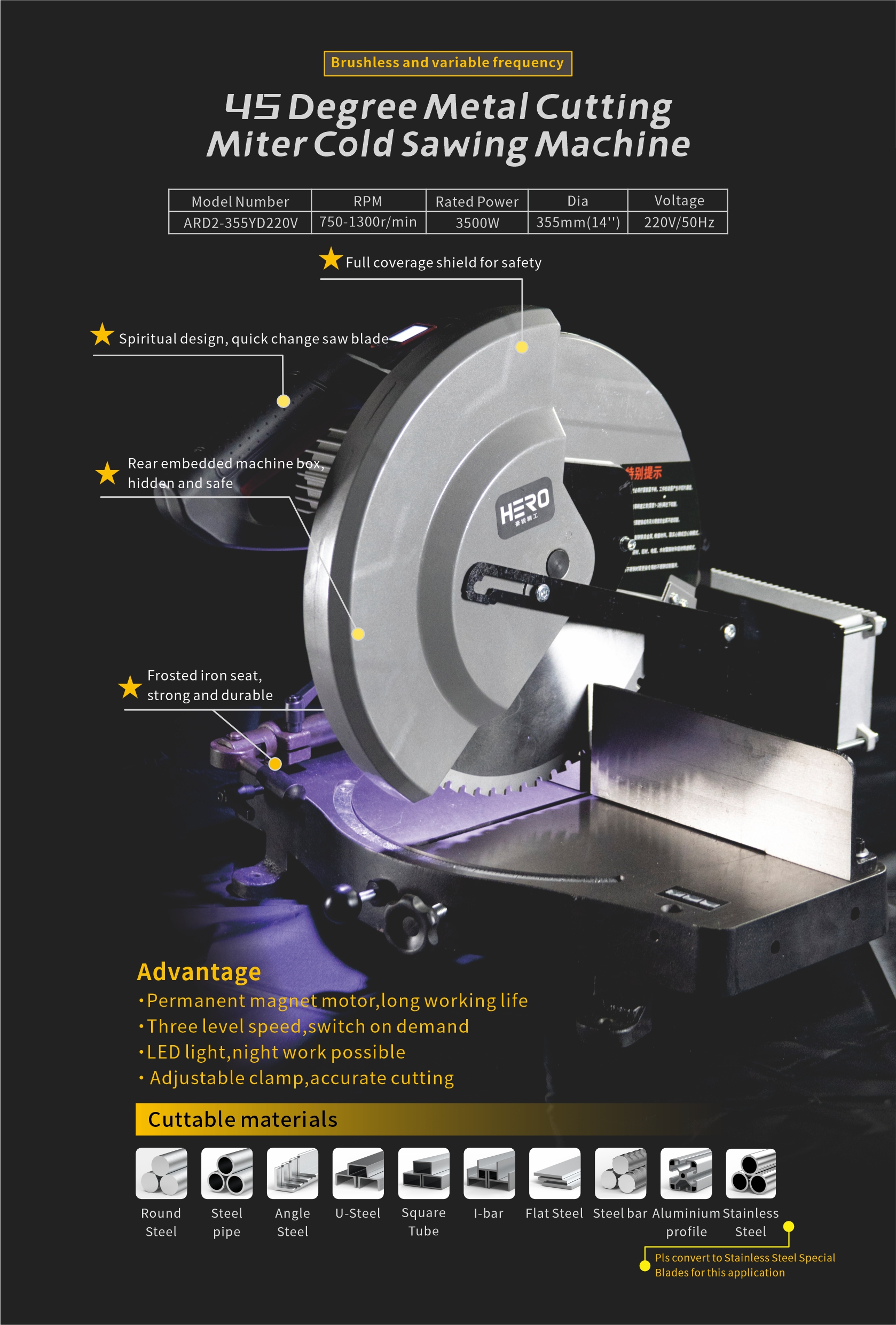

HERO Cold Metal Miter Saw Machine

-

I-Metal-Material Cutting Technology: I-Saw enye, i-Blade enye, inqumla zonke iintsimbi. Ukusika okugudileyo kwiNsimbi eRound, umbhobho wentsimbi, iAngle Steel, i-U-Steel & nokunye -

Ii-engile ezichanekileyo: 0˚ - 45˚ i-bevel tilt kunye ne-45˚ - 45˚ i-engile ye-miter -

I-Saw Balde ibandakanyiwe: I-Premium Metal Cutting blade ibandakanyiwe (355mm * 66T)

Inzuzo:

-

Injini yemagnethi esisigxina, ubomi obude bokusebenza. -

Isantya senqanaba lesithathu, tshintshela kwimfuno -

Ukukhanya kwe-LED, umsebenzi wasebusuku onokwenzeka -

I-clamp ehlengahlengiswayo, ukusika ngokuchanekileyo

Ukusika izinto ezininzi:

Intsimbi eRound, intsimbi yentsimbi, iAngle Steel,U-steel,Square Tube,I-bar,Flat Steel,Steel Bar,Aluminium Profile,Stainless Steel (Ii-pls Guqulela kwiiBladi eziKhethekileyo zentsimbi engatyiwayo kwesi Sicelo)

Ixesha lokuposa: Jun-20-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Ubungakanani Saw

HERO Panel Ubungakanani Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade

IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade HERO Aluminiyam Saw

HERO Aluminiyam Saw I-Grooving Saw

I-Grooving Saw Iprofayile yentsimbi yabona

Iprofayile yentsimbi yabona Edge Bander wabona

Edge Bander wabona Saw Acrylic

Saw Acrylic PCD Saw Blade

PCD Saw Blade PCD Ubungakanani beSaw Blade

PCD Ubungakanani beSaw Blade PCD Panel Ubungakanani Saw

PCD Panel Ubungakanani Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Saw

PCD Aluminium Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Metal Ferrous

Cold Saw Blade for Metal Ferrous Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Umtshini weSaw obandayo

Umtshini weSaw obandayo Drill Bits

Drill Bits Amasuntswana eDowel Drill

Amasuntswana eDowel Drill Ngokusebenzisa i-Drill Bits

Ngokusebenzisa i-Drill Bits Amasuntswana e-Hinge Drill

Amasuntswana e-Hinge Drill TCT Inyathelo Drill Bits

TCT Inyathelo Drill Bits HSS Drill Bits / Mortise Bits

HSS Drill Bits / Mortise Bits Amasuntswana eRouter

Amasuntswana eRouter Amasuntswana aNgqo

Amasuntswana aNgqo Amasuntswana amade athe ngqo

Amasuntswana amade athe ngqo TCT Amasuntswana aNgqo

TCT Amasuntswana aNgqo M16 Amasuntswana aNgqo

M16 Amasuntswana aNgqo TCT X Amasuntswana aNgqo

TCT X Amasuntswana aNgqo 45 Isidanga seChamfer Bit

45 Isidanga seChamfer Bit Ukukrola Bit

Ukukrola Bit Bit yeKona

Bit yeKona Amasuntswana omzila wePCD

Amasuntswana omzila wePCD Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander wabona

Edge Bander wabona I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Ezinye izixhobo & nezixhobo

Ezinye izixhobo & nezixhobo Drill Adapter

Drill Adapter Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Iimela zokucwangcisa

Iimela zokucwangcisa