intshayelelo

Ekwakhiweni nasekuveliseni izixhobo zokusika ziyimfuneko.

I-Chop Saw, i-Miter Saw kunye ne-Cold Saw imele izixhobo ezintathu eziqhelekileyo kunye nezisebenzayo zokusika. Uyilo lwabo olulodwa kunye nemigaqo yokusebenza yenza ukuba badlale indima ebalulekileyo kwimisebenzi eyahlukeneyo yokusika.

Kuphela ngesixhobo esichanekileyo sokusika esikwaziyo ukubonelela ngokucokisekileyo kunye nokusikwa ngokukhawuleza ngaphandle kokuphazamisa izinto ezichanekileyo kunye nokusika ngokukhawuleza kunokwenzeka. Ezintathu zezona blade zidumileyo; ukukhetha phakathi kwabo kunokuba nzima.

Eli nqaku liza kujonga nzulu ezi zixhobo zintathu zokusika, ukuhlalutya ukufana kwazo kunye nokwahluka kwazo, kwaye ziveze iingenelo zabo kwizicelo ezisebenzayo ukunceda abafundi baqonde ngcono indlela yokukhetha isixhobo sokusika esifanelekileyo kwiimfuno zabo zomsebenzi.

Isiqulatho

-

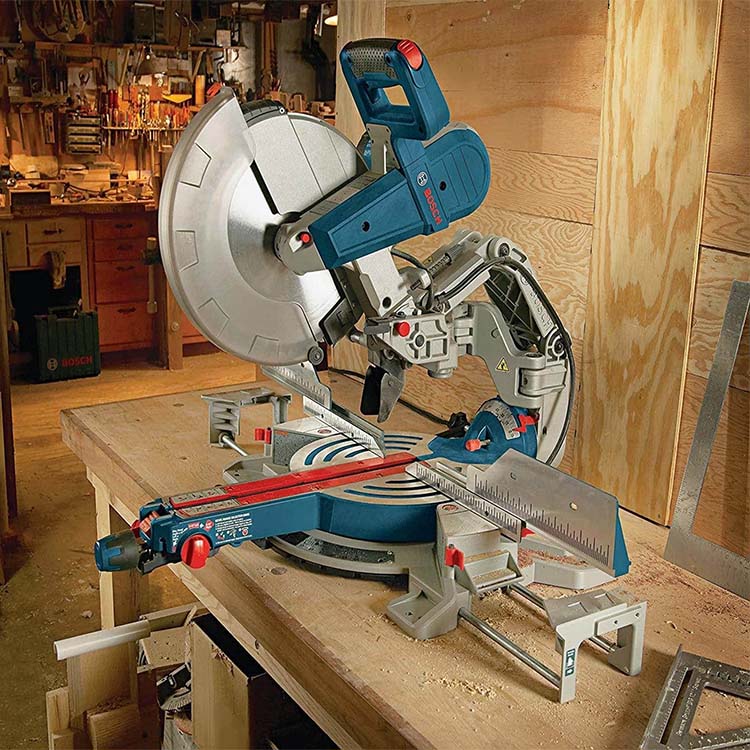

I-Miter yabona

-

Intsimbi yesarha ebandayo

-

Chop isarha

-

Eyahlukileyo

-

Ukuqukumbela

I-Miter yabona

Isarha yokulinganisa, ekwaziwa ngokuba yisarha yokulinganisa, luhlobo lwesarha esetyenziselwa ukwenza ii-crosscuts ezichanekileyo, iimiter, kunye neebevels kwiworkpiece. Ibandakanya iblayidi yesarha esetyhula exhonywe kwingalo ejingayo ekwaziyo ukujikeleza ukwenza imitha yokusikeka kwii-engile ezahlukeneyo. Ngokuxhomekeke kwimodeli, inokukwazi ukwenza i-bevel cuts ngokutyekisa i-blade

I-blade itsalwa ezantsi kwizinto eziphathekayo, ngokungafaniyo nesarha yesetyhula apho isondla khona ngezinto.

Ngokuqhelekileyo zisetyenziselwa ukusika i-wood trim kunye nokubumba, kodwa zingasetyenziselwa ukusika isinyithi, i-masonry, kunye neeplastiki, ngaphandle kokuba uhlobo olufanelekileyo lwe-blade lusetyenziselwa izinto ezisikwayo.

Ubungakanani

Iisarha zomgama ziza ngobukhulu obahlukeneyo. Ubukhulu obuqhelekileyo bubukhulu be-180, 250 kunye ne-300 mm (7 + 1⁄4, 10 kunye ne-12 in) ubukhulu be-blades, nganye inomthamo wayo wokusika.

Iisarha zeMiter zikholisa ukuza kwi-250 kunye ne-300 mm (i-10 kunye ne-12 ngaphakathi) yolungelelwaniso lwesayizi yeblade kwaye iqhele ukwenziwa ngentsimbi yekhabhoni kwaye inokuza nengubo ukwenza ukusika kube lula.

Ubume bezinyo

Uyilo lwamazinyo luza ngeendlela ezininzi ezahlukeneyo: i-ATB (i-alternating top bevel), i-FTG (i-flat top grind) kunye ne-TCG (i-triple chip grind) zezona zixhaphakileyo. Uyilo ngalunye lulungiselelwe izinto ezithile kunye nonyango lomda.

Ukusetyenziswa

Isarha iqhele ukusetyenziswa kunye neWood, kwaye inokufumaneka kwiimodeli ezahlukeneyo kunye nobukhulu.

Iisarha zemiter ziyakwazi ukwenza ukusika okuthe tye, i-miter, kunye ne-bevel.

Uhlobo

nalu uluhlu olukhulu lweesarha zokuvala ezifumanekayo kwimarike. I-bevel enye, i-bevel ephindwe kabini, i-sliding, i-compound njl.

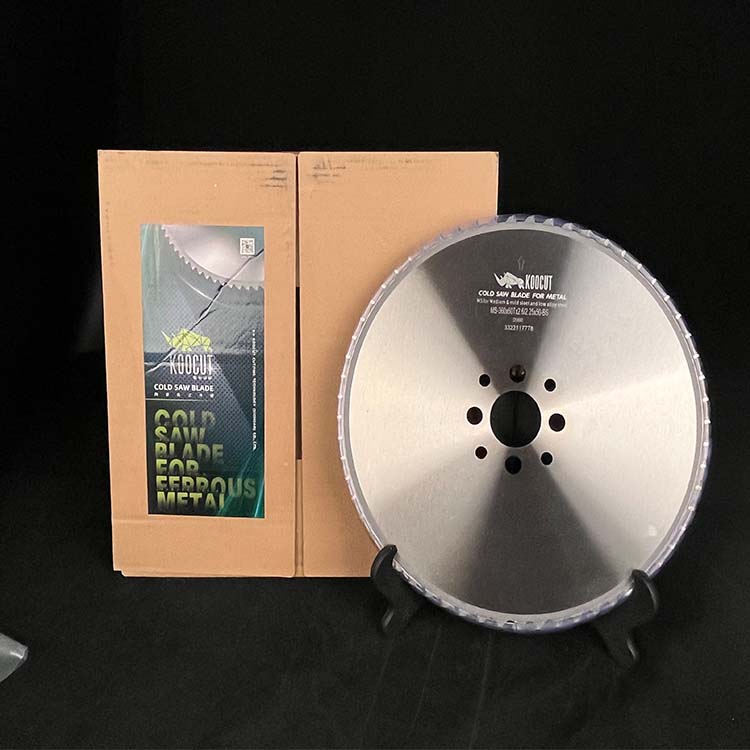

Isarha ebandayo

Aisarha ebandayoyisarha esetyhula eyenzelwe ukusika isinyithi esebenzisa i-blade enamazinyo ukuhambisa ubushushu obuveliswa ngokusika kwiitshiphusi ezenziwe nge-saw blade, evumela ukuba zombini i-blade kunye nezinto ezinqunyulwayo zihlale zipholile.Le nto ihluke kwi-saw abrasive, ekhupha isinyithi kwaye ivelise ubushushu obukhulu obufunxwa yinto enqunyulwayo kunye ne-saw blade.

Isicelo

Iisarha ezibandayo ziyakwazi ukwenza uninzi lweealloyi ezine-ferrous kunye ne-non-ferrous. Izibonelelo ezongezelelweyo ziquka imveliso encinci ye-burr, iintlantsi ezimbalwa, ukuguga okuncinci kwaye akukho luthuli.

Iisarha eziyilelwe ukusebenzisa isixokelelwano sokupholisa ngeesarha ukugcina amazinyo eesarha epholile kwaye egcotyiwe anokunciphisa iintlantsi kunye nokuguquka kombala ngokupheleleyo. Uhlobo lwe-saw blade kunye nenani lamazinyo, isantya sokusika, kunye nesantya sokutya zonke kufuneka zilungele uhlobo kunye nobukhulu bezinto ezisikwayo, ekufuneka zibotshwe ngoomatshini ukuthintela ukuhamba ngexesha lokusika.

Kodwa kukho uhlobo lwesarha ebandayo engadingi sipholisi.

Uhlobo

Iisarha ezibandayo zeCermet

Iisarha ezibandayo zeDry Cut

Cermet Cold Saw Blade

I-Cermet HSS Cold Saw luhlobo lwesarha elisebenzisa iincakuba ezenziwe ngentsimbi yesantya esiphezulu (HSS), i-carbide, okanye i-cermet ukwenza imisebenzi yokusika. I-Cermet-tipped cold saw blades zenzelwe ukusika imveliso ephezulu yeebhilithi, imibhobho, kunye neemilo ezahlukeneyo zentsimbi. Zenziwe nge-kerf ebhityileyo kwaye ziyaziwa ngomsebenzi wazo obalaseleyo wokusika kunye nobomi obandisiweyo beblade.

Oomatshini abafanelekileyo: Umatshini omkhulu wokusarha obandayo

Dry Cut Cold Saw

Iisarha ezibandayo ezinqamlekileyo ziyaziwa ngokuchaneka kwazo, zivelisa ukucutha okucocekileyo kunye ne-burr-free, okunciphisa imfuno yokugqiba okanye ukuchithwa komsebenzi owongezelelweyo. Ukungabikho kokupholisa kubangela ukuba indawo yokusebenza icoceke kwaye kuphelisa ubumdaka obunxulunyaniswa neendlela zokusika ezimanzi.

Iimpawu eziphambili zeiisarha ezibandayo ezisikiweyo ezomileyozibandakanya amazinyo abo ajikeleza ngesantya esiphezulu, ahlala exhotyiswe nge-carbide okanye amazinyo e-cermet, enzelwe ngokukodwa ukusika isinyithi. Ngokungafaniyo neesarha ezirhawukayo zemveli, iisarha ezibandayo ezisikiweyo ezomileyo zisebenza ngaphandle kwemfuneko yokupholisa okanye yokuthambisa. Le nkqubo yokusika eyomileyo inciphisa ukuveliswa kobushushu, iqinisekisa ukuba ukunyaniseka kwesakhiwo kunye neempawu zetsimbi zihlala zilungile.

Isarha ebandayo ivelisa amanxeba achanekileyo, acocekileyo, agayiweyo, ngelixa isarha ye-chop inokuzulazula kwaye ikhuphe into edla ngokufuna utyando olulandelayo lokususa i-burr kunye ne-square-up emva kokuba into ipholile. Iisarha ezibandayo zisenokushenxiswa emgceni ngaphandle kokufuna umsebenzi owahlukileyo, ogcina imali.

Oomatshini abafanelekileyo: I-Metal Cold Cutting Saw

Nangona isarha ebandayo ayimnandi njengesarha yokunqunqa, ivelisa ukusika okugudileyo okukuvumela ukuba ugqibezele umsebenzi ngokukhawuleza. Akusekho mfuneko yokuba ulinde ukuba impahla yakho iphole emva kokuba isikiwe.

Chop isarha

Iisarha ezirhaxayo luhlobo lwesixhobo samandla esisebenzisa iidiski ezirhabaxa okanye iincakuba ukusika izinto ezahlukeneyo, njengesinyithi, iiseramikhi, kunye nekhonkrithi. Iisarha ezirhabaxa zikwabizwa ngokuba ziisarha ezisikiweyo, iisarha zokusika, okanye iisarha zentsimbi.

I-saws ye-Abrasive isebenza ngokujikeleza i-disc abrasive okanye i-blade ngesantya esiphezulu kwaye ifake uxinzelelo kwizinto eziza kunqunyulwa. Iingqungquthela eziqhekezayo kwi-disc okanye i-blade zichitha izinto eziphathekayo kwaye zenze i-cut smooth and clean cut.

Ubungakanani

Idiski yokusika ngokuqhelekileyo i-14 (360 mm) ububanzi kunye ne-764 kwi-(2.8 mm) ubukhulu. Iisarha ezinkulu zinokusebenzisa iidiski ezinobubanzi obuyi-16 kwi (410 mm).

Eyahlukileyo

Iindlela zokusika:

Isarha ebandayo,Iisarha zokunqunqa zenza iindlela ezinqamlezileyo ezithe ngqo kuphela.

Iisarha zemiter ziyakwazi ukwenza ukusika okuthe tye, i-miter, kunye ne-bevel.

Igama eliphosakeleyo eliqhelekileyo elidla ngokusetyenziselwa ukubhekisela kwisarha ye-chop. Nangona zifana ngendlela ethile kwisenzo sabo sokusika, zimbini iintlobo ezahlukeneyo zeesarha. Isarha ye-chop yenzelwe ngokukodwa ukusika isinyithi kwaye idla ngokusetyenziswa ngelixa ibekwe mcaba emhlabeni ngencakuba emiswe kuma-90° ngokuthe nkqo. Isarha ye-chop ayikwazi ukwenza i-miter cut ngaphandle kokuba isetyenziswe ngumqhubi ngokuchasene nomsebenzi womatshini ngokwawo.

Isicelo

Isarha yonkontsho ilungele ukugawula iinkuni.

Ngokungafaniyo neesarha zetafile kunye neesarha zebhendi, zigqwesile xa kufikwa kwizixhobo zokusika ezinje ngamaplanga anobukhulu bokubumba, ukuhombisa, okanye ukubeka umgangatho.

Isarha ebandayo kunye nesarha yokunqunqa yeyokusika isinyithi, kodwa isarha ebandayo inokusika Uluhlu olubanzi lwemathiriyeli kunesarha yokunqunqa.

Kwaye ukusika kukhawuleza ngakumbi

Ukuqukumbela

Njengesixhobo sokusika esiguquguqukayo nesisebenzayo,iSaw Chopugqwesa ekusikeni ngokuthe ngqo iintlobo ngeentlobo zemathiriyeli. Ubume bayo obulula kodwa obunamandla buyenza isetyenziswe ngokubanzi kwiindawo zokwakha kunye nezinye iimeko.

I-Miter Saw'sukuguquguquka kokulungelelaniswa kwe-angle kunye nokusika i-bevel kuyinzuzo ebalulekileyo, okwenza kube yinto efanelekileyo yokwenza umthi kunye nomsebenzi wokuhlobisa. Uyilo lwayo luvumela abasebenzisi ukuba benze ngokulula ii-engile ezahlukeneyo kunye nokusikwa kwe-bevel.

Saw ebandayoiyodwa kwintsimi yokusika isinyithi kunye neteknoloji yayo yokusika ebandayo. Ukusetyenziswa kobuchwepheshe bokusika okubandayo akugcini nje ukwandisa isantya sokusika, kodwa kuqinisekisa iziphumo zokusika ezichanekileyo, ezifanelekileyo ngokukhethekileyo kwimiboniso efuna ukusebenza kwezinto eziphezulu.

Ukuba unomdla, sinokukunika izixhobo ezingcono.

Ixesha lokuposa: Dec-30-2023

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Ubungakanani Saw

HERO Panel Ubungakanani Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade

IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade HERO Aluminiyam Saw

HERO Aluminiyam Saw I-Grooving Saw

I-Grooving Saw Iprofayile yentsimbi yabona

Iprofayile yentsimbi yabona Edge Bander wabona

Edge Bander wabona Saw Acrylic

Saw Acrylic PCD Saw Blade

PCD Saw Blade PCD Ubungakanani beSaw Blade

PCD Ubungakanani beSaw Blade PCD Panel Ubungakanani Saw

PCD Panel Ubungakanani Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Saw

PCD Aluminium Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Metal Ferrous

Cold Saw Blade for Metal Ferrous Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Umtshini weSaw obandayo

Umtshini weSaw obandayo Drill Bits

Drill Bits Amasuntswana eDowel Drill

Amasuntswana eDowel Drill Ngokusebenzisa i-Drill Bits

Ngokusebenzisa i-Drill Bits Amasuntswana e-Hinge Drill

Amasuntswana e-Hinge Drill TCT Inyathelo Drill Bits

TCT Inyathelo Drill Bits HSS Drill Bits / Mortise Bits

HSS Drill Bits / Mortise Bits Amasuntswana eRouter

Amasuntswana eRouter Amasuntswana aNgqo

Amasuntswana aNgqo Amasuntswana amade athe ngqo

Amasuntswana amade athe ngqo TCT Amasuntswana aNgqo

TCT Amasuntswana aNgqo M16 Amasuntswana aNgqo

M16 Amasuntswana aNgqo TCT X Amasuntswana aNgqo

TCT X Amasuntswana aNgqo 45 Isidanga seChamfer Bit

45 Isidanga seChamfer Bit Ukukrola Bit

Ukukrola Bit Bit yeKona

Bit yeKona Amasuntswana omzila wePCD

Amasuntswana omzila wePCD Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander wabona

Edge Bander wabona I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Ezinye izixhobo kunye nezixhobo

Ezinye izixhobo kunye nezixhobo Drill Adapter

Drill Adapter Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Iimela zokucwangcisa

Iimela zokucwangcisa