Indlela yokukhetha phakathi kwesarha yokusika yentsimbi rhoqo kunye nesarha yeSetyhula ebandayo?

Kwiivenkile ezininzi zesinyithi, xa usika isinyithi, ukhetho lwe-saw blade lunokuba nefuthe elibalulekileyo ekusebenzeni okusikiweyo kunye nomgangatho.Ukwenza ukhetho olungalunganga lulimaza imveliso yakho yexesha elifutshane. Ekuhambeni kwexesha, kunokunciphisa amathuba akho okufumana abathengi abafuna ukucuthwa okuthile kwizinto ezithile.

Ukukunceda wenze ukhetho olufanelekileyo, kufuneka ukwazi izinto eziluncedo kunye nezingeloncedo zeesarha ezibandayo kunye neesarha zokusika zentsimbi rhoqo.

Yintoni isarha ebandayo

Iisarha ezibandayo zisebenzisa isarha yesarha esetyhula ukusika iintlobo ngeentlobo zesinyithi ezibandakanya isinyithi. Njengoko igama lisitsho, isarha ebandayo yenza umsebenzi wayo ngokufanelekileyo, ngelixa ikhusela i-blade kunye nentsimbi ekutshiseni kakhulu. Iisarha ezibandayo ziqhelekile ngoomatshini abamileyo kwaye hayi ibhentshi-phezulu, ezahlukeneyo eziphathwayo.

Ingumatshini wokusika osetyenziselwa ukusika isinyithi ngesantya esiphezulu ngaphandle kokudala ukushisa okukhulu, iintlantsi okanye uthuli. I-cold sawing isebenzisa i-blade ejikelezayo ukususa izinto ngelixa uhambisa ubushushu obuveliswayo kwiitshiphu ezenziwe nge-saw blade. Ubushushu obuveliswa ngexesha lokusikwa ngesarha ebandayo kudluliselwa kwi-burrs eyenziwe endaweni yezinto ezisikiweyo, ngaloo ndlela i-workpiece ihlala ibanda.

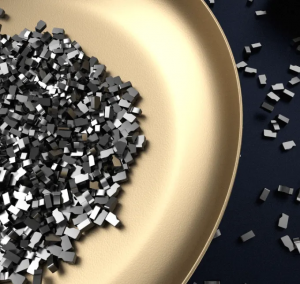

Isarha ebandayo isebenzisa nokuba yintsimbi eqinileyo enesantya esiphezulu (HSS) okanye iblade ye-tungsten carbide-tipped (TCT) ejika kwi-RPMs esezantsi.

Ngokuchaseneyo negama, ii-HSS blades azifane zisetyenziswe ngesantya esiphezulu. Endaweni yoko, uphawu lwabo oluphambili bubulukhuni, obubanika ukuxhathisa okuphezulu kubushushu kunye nokunxiba, ukuxhathisa ukunxitywa kwangaphambi kwexesha okunokuchaphazela ukugqiba kwamalungu asikiweyo. . Iibhleyidi ze-TCT zibiza kakhulu kodwa zikwanzima kakhulu kwaye ziyakwazi ukusebenza kumaqondo obushushu aphezulu nangaphezulu kune-HSS. Oku kuvumela ii-TCT ii-saw blades ukuba zisebenze ngesantya esikhawulezayo kune-HSS blades, ukunciphisa kakhulu ixesha lokusika.

Izinto eziluncedo zokusebenzisa isarha ebandayo

Iisarha ezibandayo zingasetyenziselwa ukusika iimilo ezininzi ezahlukeneyo, kubandakanywa iintonga, iityhubhu, kunye ne-extrusions. Iisarha ezizenzekelayo, ezivaliweyo ezijikelezayo ezibandayo zisebenza kakuhle kwiiprojekthi zemveliso kunye neeprojekthi eziphindaphindiweyo apho ukunyamezela kunye nokugqiba kubalulekile. Aba matshini banikezela ngesantya se-blade eguquguqukayo kunye namazinga okutya alungelelanisiweyo kwimveliso enesantya esiphezulu kunye ne-burr-free, ukusikwa okuchanekileyo.

Iisarha ezibandayo, kunye namazinyo azo, zenza ukusika okucocekileyo ngaphandle kwemiphetho edibeneyo. Ngelixa iincakuba ezirhabaxa ziqhele ukuzulazula, nakwizikeyi ezithe tye, iincakuba ezinamazinyo zixhomekeke ngakumbi ekusikeni okuthe tye okanye okune-engile.Ngencakuba elungileyo, ebukhali, isarha ebandayo ejikelezayo ekhawulezayo ineengenelo zokuphelisa iintlantsi kwaye ingavelisi iintlantsi, ukujika kombala, okanye uthuli. Ngoko ke, indlela ngokubanzi ihambisa umgangatho ophezulu ogqityiweyo kunye nee-edges zokwenyani.Bakwayinto encinci emdaka ngaphandle kothuli olurhabaxa olufumana kuyo yonke into kwindawo yayo.

Inkqubo yokusarha ebandayo iyakwazi ukugqithisa okuphezulu kwiintsimbi ezinkulu kunye ezinzima - kwiimeko ezithile, nangona ziqinile njenge-± 0.005 "(0.127 mm) ukunyamezela.

Ungagcina imali ngesarha ebandayo

Nangona ixabiso lokuqala leblade yesarha ebandayo linokuba phezulu kunediski erhawukileyo, ungaphinda uyilole iblayidi enencam ye-carbide amaxesha amaninzi, ukuguqulela kugcino olubalulekileyo. Iisarha ezibandayo nazo zonga ixesha kunye nemali ngokwenza amanxeba achanekileyo.

Ezi zicucu zingenasiphako azifuni umsebenzi wokugqiba okwesibini, ukonga abasebenzi abaninzi kwiimeko ezininzi. Ukusikwa okuchanekileyo kuseyenye inzuzo njengoko iisarha ezisikiweyo ezibandayo zinokubamba ukunyamezelana, kwakhona ziphelise ukusebenza kwexabiso lesibini lesibini.

Ngaba isarha ebandayo lukhetho olulungileyo kwisicelo sakho sokusika isinyithi?

Ngaphambi kokuba ukhethe i-sawing ebandayo kwindawo yakho yentsimbi, kubalulekile ukuqonda iingenelo kunye nokungalunganga kwenkqubo. Ngaloo ndlela, unokuvavanya kwaye wenze isigqibo sokuba ingaba-okanye nayiphi na enye indlela yokusika isinyithi echanekileyo onokuthi uyithathele ingqalelo-iya kuhlangabezana neemfuno zakho kunye nezinto eziphambili.

Iingxaki zokusebenzisa isarha ebandayo

Nangona kunjalo, i-sawing ebandayo ayifanelekanga ubude obungaphantsi kwe-0.125 "(3.175 mm). Ukongezelela, indlela ngokwenene inokuvelisa i-burrs enzima. Ngokukodwa, ngumcimbi apho une-ODs phantsi kwe-0.125 "(3.175 mm) kunye nee-ID ezincinci kakhulu, apho ityhubhu iya kuvalwa yi-burr eveliswa yi-cold saw.

Enye into engathandekiyo kwiisarha ezibandayo kukuba ukuqina kwenza iincakuba zeesarha zibe brittle kwaye zixhomekeke kumothuko. Naliphi na inani lokungcangcazela - umzekelo, ukusuka ekubambeni okunganelanga kwenxalenye okanye izinga lokutya elingalunganga - linokonakalisa ngokulula amazinyo esarha. Ukongeza, iisarha ezibandayo zihlala zibangela ukulahleka okukhulu kwekerf, okuguqulela kwimveliso elahlekileyo kunye neendleko eziphezulu.

Nangona i-sawing ebandayo ingasetyenziselwa ukusika ezininzi i-alloys ene-ferrous kunye ne-non-ferrous, ayikhuthazwa kwiintsimbi ezinzima kakhulu-ngokukodwa, ezo zinzima kune-saw ngokwayo. Kwaye ngelixa iisarha ezibandayo zinokwenza ukusika okuhlanganisiweyo, kunokukwenza kuphela ngeengxenye ezincinci zedayamitha kunye nokulungiswa okukhethekileyo kuyafuneka.

Iincakuba zesarha zokusika eziqhelekileyo:

1. Indlela yokusika: Iintsimbi eziqhelekileyo zokusika ii-saw blades, kwelinye icala, ngokuqhelekileyo zisebenzisa i-abrasive okanye i-high-speed steel teeth ukusika isinyithi. Ezi blades zivelisa ubushushu obuninzi ngexesha lenkqubo yokusika, enokubangela i-burrs kunye ne-thermal deformation ye-workpiece.

2. Ukuhambelana kwezinto eziphathekayo: Iintsimbi eziqhelekileyo zokusika ii-saw blades zifanelekile ukusika iintsimbi ezithambileyo ezifana nentsimbi epholileyo, intsimbi kunye nezinye izinto ezifanayo. Ezi blades ziqhele ukusetyenziswa kwimveliso jikelele kunye nezicelo zokwakha apho ukusika ngokuchanekileyo kungeyona nkxalabo enkulu.

3. Ubomi be-Blade: Iintsimbi eziqhelekileyo zokusika ii-saw blades zingafumana ukunxiba ngokukhawuleza ngenxa yobushushu obuphezulu obuveliswa ngexesha lokusika. Ngoko ke, zinokufuna ukutshintshwa rhoqo, ngakumbi xa zisetyenziselwa imisebenzi enzima yokusika.

4. Ukusika isantya kunye nokusebenza kakuhle: ii-saw blades zentsimbi ngokubanzi ziyaziwa ngesantya esiphezulu sokusika, okwenza ukuba zilungele ukukhawuleza, ukusikwa okurhabaxa kwiintsimbi ezinentsimbi. Nangona kunjalo, ukushisa okwenziwa ngexesha lenkqubo yokusika kunokuchaphazela umgangatho wokusika kunye nokugqitywa okongeziweyo kunokufuneka ukufezekisa umphumo oyifunayo.

ukuququmbela:

Isishwankathelo, ukhetho phakathi kweesarha ezibandayo kunye neesaha zentsimbi eziqhelekileyo zixhomekeke kwiimfuno ezithile zesicelo sokusika isinyithi. Iincakuba zesarha ezibandayo zezona zingcono ukusika iintsimbi ezingeyontsimbi ezichanekileyo, zinika amanxeba acocekileyo, angenaburr kunye nokwandisa ubomi bencakuba. Ngakolunye uhlangothi, ii-saw blades zentsimbi eziqhelekileyo zilungile ngokukhawuleza, ukusika okukrakra kwiintsimbi zentsimbi, nangona kunokufuna iinkqubo zokugqiba ezongezelelweyo. Ukuqonda umahluko phakathi kwezi ntlobo zimbini zee-saw blades kubalulekile ekukhetheni eyona ndlela ifanelekileyo yomsebenzi onikiweyo wokusika isinyithi.

Khangela isarha ebandayo ejikelezayo ukuba umsebenzi wakho:

-

Usika imathiriyeli ngokubanzi ayinkulu kakhulu -

Yenza isixa esikhulu sokusika imitha -

Kufuneka ivelise izinto ezigqityiweyo ezicocekileyo ezifuna imisebenzi yesibini -

Kufuneka kuthintelwe imathiriyeli yokufudumeza okanye ukwenza ii-burrs kwimida esikiweyo -

Uzimisele ukuhlawula ngaphezulu, kodwa ufumana i-ROI ephezulu

Khumbula, ezi blade zeesarha lutyalo-mali lwexesha elide. Qwalasela iimfuno zakho zangoku nezexesha elizayo xa usenza ukhetho. Isarha elungileyo iya konyusa inzuzo yakho kunye nokusebenza kakuhle iminyaka.

Ukufumana ngakumbi,gcwalisa ifomu yethu yoqhagamshelwano,okanyesithumele i-imeyile.

Ixesha lokuposa: Sep-14-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Ubungakanani Saw

HERO Panel Ubungakanani Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade

IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade HERO Aluminiyam Saw

HERO Aluminiyam Saw I-Grooving Saw

I-Grooving Saw Iprofayile yentsimbi yabona

Iprofayile yentsimbi yabona Edge Bander wabona

Edge Bander wabona Saw Acrylic

Saw Acrylic PCD Saw Blade

PCD Saw Blade PCD Ubungakanani beSaw Blade

PCD Ubungakanani beSaw Blade PCD Panel Ubungakanani Saw

PCD Panel Ubungakanani Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Saw

PCD Aluminium Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Metal Ferrous

Cold Saw Blade for Metal Ferrous Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Umtshini weSaw obandayo

Umtshini weSaw obandayo Drill Bits

Drill Bits Amasuntswana eDowel Drill

Amasuntswana eDowel Drill Ngokusebenzisa i-Drill Bits

Ngokusebenzisa i-Drill Bits Amasuntswana e-Hinge Drill

Amasuntswana e-Hinge Drill TCT Inyathelo Drill Bits

TCT Inyathelo Drill Bits HSS Drill Bits / Mortise Bits

HSS Drill Bits / Mortise Bits Amasuntswana eRouter

Amasuntswana eRouter Amasuntswana aNgqo

Amasuntswana aNgqo Amasuntswana amade athe ngqo

Amasuntswana amade athe ngqo TCT Amasuntswana aNgqo

TCT Amasuntswana aNgqo M16 Amasuntswana aNgqo

M16 Amasuntswana aNgqo TCT X Amasuntswana aNgqo

TCT X Amasuntswana aNgqo 45 Isidanga seChamfer Bit

45 Isidanga seChamfer Bit Ukukrola Bit

Ukukrola Bit Bit yeKona

Bit yeKona Amasuntswana omzila wePCD

Amasuntswana omzila wePCD Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander wabona

Edge Bander wabona I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Ezinye izixhobo kunye nezixhobo

Ezinye izixhobo kunye nezixhobo Drill Adapter

Drill Adapter Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Iimela zokucwangcisa

Iimela zokucwangcisa