Malunga nokusika isinyithi, sinezixhobo ezininzi zokuyisika. Kodwa ngaba uyawazi ngokwenene umahluko phakathi kwazo?

Nalu ulwazi ongenakukwazi ukuluphosakela!

Isiqulatho

-

Cold Saw Basics

-

Ukuthelekisa kunye namavili okugaya amasiko kunye neenkcukacha zokusika

-

FAQ malunga neCold Saw Use kunye noFakelo

-

Ukuqukumbela

Cold Saw Basics

Ukusarha ebandayo, okanye intsimbi yokusarha ebandayo, sisishunqulelo senkqubo yokusarha yoomatshini besinyithi setyhula. Kwinkqubo yokusarha yesinyithi, ubushushu obuveliswa xa isarha isarha i-workpiece igqithiselwa kwi-sawdust ngamazinyo, kwaye i-workpiece esarha kunye ne-saw blade igcinwa ipholile, ngoko ibizwa ngokuba yi-cold saw.

1. Iimpawu zokusika ezibandayo

Ukuchaneka okuphezulu kwe-workpiece, uburhabaxa obuhle bomgangatho, ukunciphisa ngokufanelekileyo ukucutshungulwa kwenkqubo elandelayo;

Isantya sokucubungula ngokukhawuleza, ukuphucula ngokufanelekileyo ukusebenza kwemveliso;

Iqondo eliphezulu lokuzenzekelayo, umntu omnye unokusebenzisa izixhobo ezininzi, ukunciphisa ngokufanelekileyo iindleko zabasebenzi;

I-workpiece ayiyi kuvelisa i-deformation kunye notshintsho lwentlangano yangaphakathi;

Inkqubo yokusarha iphantsi kwiintlantsi, uthuli kunye nengxolo.

2: Injongo yokuSarha

Injongo yokusarha kukufumana isiphumo esikumgangatho ophezulu

Emva koko ngokusekelwe kule migaqo ingasentla, sinokuzoba ifomyula.

Isiphumo esihle sokusarha = izixhobo zokusarha zokuthelekisa ezikumgangatho ophezulu + isarha yesarha ekumgangatho ophezulu + iiparamitha ezichanekileyo zokusarha

Kuxhomekeka kule fomyula, ukuze sikwazi ukulawula umphumo we-sawing kwi-aspect ye-3.

I-3: Isarha ebandayo yentsimbi-Izixhobo eziqhelekileyo zokuqhuba

Izinto zokusika ezilungisekayo:

Umjelo wentsimbi ,I-beam, intsimbi engqukuva, umbhobho wentsimbi, ialloyi yealuminiyam

Izinto zokusika ezingenakulungiswa:

Insimbi engenasici (ifuna i-blade yesarha ekhethekileyo) Intsimbi yentsimbi ecinyiweyo kunye nentsimbi epholileyo

Ezi zizixhobo eziqhelekileyo ezinokusikwa kunye nezo zingenakunqunyulwa

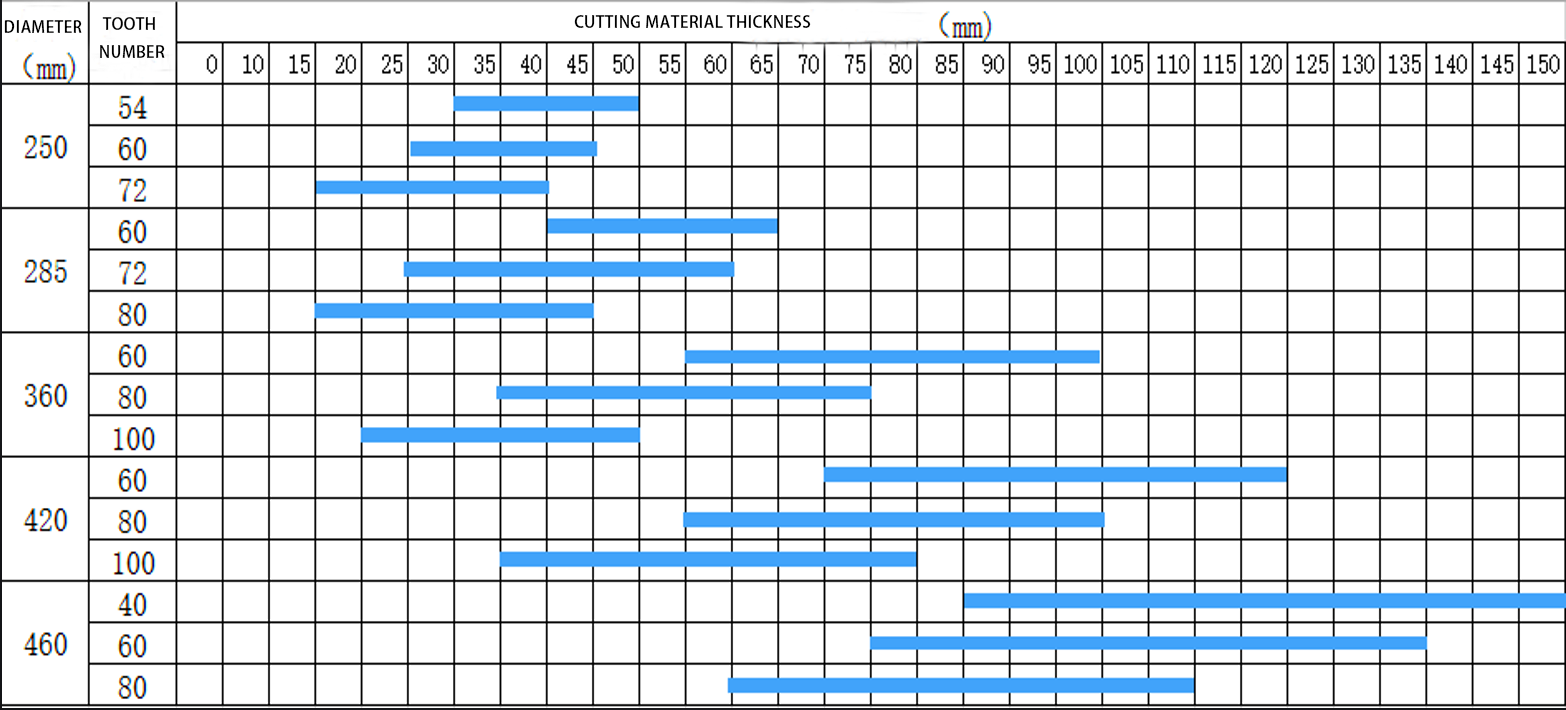

Kwangaxeshanye, ubungakanani bokukhethwa kweentsimbi ezibandayo zentsimbi nazo kufuneka zisekelwe kubunzima bezinto zokusika.

Njengoko kule theyibhile ingezantsi.

Ukuthelekisa kunye namavili okugaya amasiko kunye neenkcukacha zokusika

Idiskhi yevili lokuSila

Idiskhi yokusika yeyevili lokugaya. Yenziwe nge-abrasive kunye ne-binder resin yokusika isinyithi esiqhelekileyo, isinyithi esingenasici kunye nezinto ezingezona zetsimbi. Ikwahlulwe kwi-resin cutting disc kunye ne-diamond yokusika i-disc.

Ukusebenzisa i-fiber yeglasi kunye ne-resin njengezinto eziqiniweyo zokudibanisa, ine-tensile ephezulu, impembelelo kunye namandla okugoba, kwaye isetyenziswa ngokubanzi kwimveliso kunye nokugqunywa kwentsimbi eqhelekileyo, intsimbi engatyiwayo kunye nengeyontsimbi.

Kodwa iidiski zamavili okusila zisetyenziswa ngabantu. Kukho ezinye iintsilelo ezingenako ukuhoywa.

Metal ukusika iisarha ezibandayo ukusombulula ezi ntlungu kakuhle kakhulu.

Kwelandelayo, siza kuxubusha le mibandela ilandelayo.

1 Ukhuseleko

Idiskhi yevili lokugaya: ukhuseleko olunokwenzeka. Abaqhubi banokuphefumlela into eninzi ye-particulate kwi-disc yevili lokugaya ngexesha lenkqubo yokusika, ebangela iingxaki zempilo kunye nokubeka ingozi yomlilo. Izinto zokusika zikholisa ukuba neentlantsi ezinkulu.

Ngaxeshanye, ivili lokugaya liphuka lula, libangela ingozi efihliweyo yokhuseleko lwabasebenzi.

Iintsimbi zevili lokusila kwimveliso kufuneka zibe nomgangatho ozinzile kwaye kungabikho ziphene, kuba nayiphi na i-saw blade breakage inokubangelwa ziziphene ezincinci. Yakuba yaphulwe, iya kubangela ingozi ebantwini.

Ngethuba lenkqubo yokusika, kuyimfuneko ukuba uhlale ubeke ingqalelo ukuba kukho imilo engaqhelekanga okanye ukuqhekeka. Ukuba kukho nayiphi na imeko, kuyimfuneko ukuyeka ukusebenzisa kunye nokubuyisela ivili lokugaya ngokukhawuleza.

Isarha ebandayo: akukho thuli kunye neentlantsi ezincinci ngexesha lokusika. Ingozi yokhuseleko incinci. Abaqhubi banokuyisebenzisa ngokuzithemba. Ngelo xesha, umgangatho kunye nobunzima beesarha ezibandayo ziphuculwe kakhulu xa kuthelekiswa namavili okugaya.

Ubomi bokusika bude kakhulu kunobo bokugaya iidiski.

2 Ukusika umgangatho

Ukusebenza kakuhle kokusika i-Disc ye-grinding wheel cutting iphantsi, kwaye ngokubanzi ifuna ukusika okuphindaphindiweyo ukugqiba umsebenzi. Ukongezelela, ukuchaneka kokusika kwevili lokugaya kuncinci, kwaye kunzima ukuhlangabezana neemfuno zokusika okuphezulu.

Ukusebenza kakuhle kokucubungula kuphantsi, ixabiso elipheleleyo liphezulu, kwaye ubuninzi bomsebenzi womsebenzi buphezulu ngenxa yokujikeleza kwesantya esiphezulu sevili lokugaya elicwangcisiweyo kunye nesitya sokusika, esenza uthuli oluninzi kunye nengxolo.

Icandelo lomnqamlezo wezinto zokusika liguquliwe kwaye line-flatness embi.

Ngokuqhelekileyo, amazinyo ambalwa iblade enawo, kokukhona iya kusikeka ngokukhawuleza, kodwa kokukhona igaqa kakhulu. Ukuba ufuna isicoci, ukusika okuchanekileyo, kufuneka ukhethe i-blade enamazinyo amaninzi.

I-Cold Saw Blade:

Ukusika okubandayo: Iqondo lokushisa eliveliswe ngexesha lentsimbi ebandayo liphantsi, elinciphisa ukuguqulwa kwe-thermal kwindawo yokusika kunye nokuqina kwezinto.

Ukusika okugudileyo: Xa kuthelekiswa neendlela zendabuko zokusika i-thermal, iisarha ezibandayo zetsimbi zivelisa ukusikeka okucolekileyo, ukunciphisa imfuno yokucutshungulwa okulandelayo.

Ukuchaneka: Ngenxa yokusetyenziswa kwetheknoloji yokusika ebandayo, i-saws yensimbi ebandayo inokubonelela ngemilinganiselo echanekileyo yokusika kunye neendawo zokusika iiflethi.

Ukusika ngokufanelekileyo: Iisarha ezibandayo zentsimbi zinokusika ngokukhawuleza ngeesarha ezijikelezayo ezijikelezayo ngesantya esiphezulu ukuphucula ukusebenza kakuhle kwemveliso. Oku kwenza ukuba iisarha ezibandayo zigqwese kwiimeko ezifana nemveliso ephezulu kunye nokuhanjiswa ngokukhawuleza ekufuneka kwenziwe ngokukhawuleza.

Ukusarha okubandayo kukwanosetyenziso oluphantsi lwamandla kunye nongcoliseko lokusingqongileyo. Ngenxa yokuba iisarha ezibandayo zisebenzisa izithambiso ukunciphisa ubushushu, zisebenzisa amandla amancinci kuneesarha ezishushu. Ngexesha elifanayo, inkqubo yokusika i-saw ebandayo ayiyi kuvelisa umsi ocacileyo kunye neegesi eziyingozi, ezinciphisa ukungcola kwendalo.

Izinto zokusika, icandelo lisicaba, lithe nkqo ngaphandle kwe-burrs.

Sebenzisa izinto ezikumgangatho ophezulu, ukuxhathisa impembelelo, akukho kuqhaqha izinyo

3:Ukusika idatha

I-Flat Steel 1cm * 8cm, imizuzwana emi-6 Ukuthwala intsimbi 6cm, imizuzwana eyi-11

Square Steel 2cm * 4cm, 3 imizuzwanaUbubanzi be-3.2cml,3 imizuzwana

Round Steel 5cm, 10 imizuzwana

Intsimbi yesarha ebandayokuthatha kuphela imizuzwana eyi-10 ukucubungula intsimbi engqukuva eyi-50mm.

I-disc yokusika ivili lokugaya ithatha ngaphezu kwemizuzwana engama-50 ukucubungula i-50 yentsimbi ejikelezayo, kwaye ukuchasana kuya kuba mkhulu kwaye kukhulu.

FAQ malunga neCold Saw Use kunye noFakelo

FAQ

1:I-saw blade ibuyiselwe umva. Akukho mfuneko yesalathiso kwivili lokusila, kwaye isarha yokusika eyomileyo ayinakusetyenziswa umva.

2: Isixhobo siqala ukubonwa ngaphambi kokufikelela kwisantya sokusebenza.

3: Ukusika ngaphandle kokubamba i-workpiece okanye enye imisebenzi engekho mthethweni yokulungisa i-workpiece ngokungekho mthethweni.

4: Yisebenzise ngesantya esingalinganiyo xa usarha, okukhokelela kwiziphumo ezingonelisiyo ezinqamlezileyo.

5: Xa ubukhali bokusika bungonelanga, susa isarha ngexesha, yilungise, kwaye wandise ubomi bokusika.

IiMfuno zoFakelo lwe-Saw Blade

-

I-saw blade kufuneka iphathwe ngononophelo kwaye mayingangqubani nezinto zangaphandle ukuphepha umonakalo kwi-blade edge okanye ukuguqulwa komzimba we-saw blade. -

Ngaphambi kokufaka i-saw blade, kufuneka uqinisekise ukuba i-flanges yangaphakathi nangaphandle yesixhobo ayinayo i-wear kunye ne-bumps ukuqinisekisa ukunyanzeliswa kwayo. -

Qinisekisa kwaye ulungise isimo sokunxiba sebrashi yocingo. Ukuba ukunxiba kugqithise, yibuyisele kwangethuba (ibrashi yocingo idlala indima ebalulekileyo ekususweni kwetshiphu). -

Coca amabala e-oyile kunye neefayili zentsimbi kwiikona zesixhobo sokuphotha, ibrashi yocingo, ibhloko yokubopha, i-flange kunye nesikhuselo sokukhusela ukuqinisekisa ukuba akukho nto yangaphandle ehlalayo. -

Emva kokufaka i-saw blade naphambi kokuqinisa izikhonkwane, qinisa i-saw blade kwicala elichaseneyo ukuze uphelise umsantsa phakathi komngxuma wokumisa kunye nephini lokumisa kwaye ugweme i-toothing ye-saw blade. -

Emva kokuqinisekisa ukuba i-nut ivaliwe, vala isigqubuthelo somatshini, vula i-injection ye-fuel injection (isixa seoli kufuneka sanele), singenzi lutho malunga nemizuzu emi-2, misa umatshini kwaye ukhangele ukuba kukho imikrwelo okanye ukushisa phezu kwendawo ye-saw blade. Imveliso eqhelekileyo inokuqhutywa kuphela ukuba akukho ziphazamiso. -

Khetha iiparamitha zokusika ezifanelekileyo ngokusekelwe kwiimpawu zezinto eziza kunqunyulwa. Ngokomgaqo, kwizinto ezinzima ukuzisika, isantya sokubona kunye nesantya sokutya akufanele sibe sigqithise. -

Xa usarha, gweba ukuba i-sawing iqhelekile ngokujonga isandi sokubona, indawo enqunyiweyo yento, kunye nemilo yokugoqa yeefayili zentsimbi. -

Xa usika nge-saw blade entsha, ukwenzela ukuba kuqinisekiswe ukuzinza kwe-saw blade, iiparitha zokusika zingancitshiswa ukuya kwi-80% yesantya esiqhelekileyo ngexesha lokusika kokuqala (esibizwa ngokuba sisixhobo sokugijima-kwinqanaba), kunye nokubuyela kwi-sawing eqhelekileyo emva kwexesha elithile. ukusika isantya.

Ukuqukumbela

Ukucutshungulwa kwesinyithi yindlela enzima yokucubungula kwintsimi yokubona. Ngenxa yeempawu zeemveliso ezicutshungulwayo, iimfuno eziphezulu kunye nemigangatho ephezulu imiselwe ukuyila, ukuveliswa kunye nokusetyenziswa kwee-saw blades.

Xa kuthelekiswa ne-saw blades yangaphambili, isarha ebandayo isombulule iingxaki ezithile kakuhle, kunye nokusebenza kwayo okuphezulu kokusika.

I-Cold saw yimveliso ehamba phambili kwi-metal processing kunye nokusika kwixesha elizayo.

Sihlala sikulungele ukukubonelela ngezixhobo zokusika ezifanelekileyo.

Njengomthengisi wee-saw blades ezijikelezayo, sinikezela ngeempahla zeprimiyamu, iingcebiso zemveliso, inkonzo yobuchwephesha, kunye nexabiso elihle kunye nenkxaso ekhethekileyo emva kokuthengisa!

Kwi https://www.koocut.com/.

Yaphula umda kwaye uye phambili ngenkalipho! Sisilogeni sethu.

Ixesha lokuposa: Sep-01-2023

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Ubungakanani Saw

HERO Panel Ubungakanani Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade

IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade HERO Aluminiyam Saw

HERO Aluminiyam Saw I-Grooving Saw

I-Grooving Saw Iprofayile yentsimbi yabona

Iprofayile yentsimbi yabona Edge Bander wabona

Edge Bander wabona Saw Acrylic

Saw Acrylic PCD Saw Blade

PCD Saw Blade PCD Ubungakanani beSaw Blade

PCD Ubungakanani beSaw Blade PCD Panel Ubungakanani Saw

PCD Panel Ubungakanani Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Saw

PCD Aluminium Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Metal Ferrous

Cold Saw Blade for Metal Ferrous Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Umtshini weSaw obandayo

Umtshini weSaw obandayo Drill Bits

Drill Bits Amasuntswana eDowel Drill

Amasuntswana eDowel Drill Ngokusebenzisa i-Drill Bits

Ngokusebenzisa i-Drill Bits Amasuntswana e-Hinge Drill

Amasuntswana e-Hinge Drill TCT Inyathelo Drill Bits

TCT Inyathelo Drill Bits HSS Drill Bits / Mortise Bits

HSS Drill Bits / Mortise Bits Amasuntswana eRouter

Amasuntswana eRouter Amasuntswana aNgqo

Amasuntswana aNgqo Amasuntswana amade athe ngqo

Amasuntswana amade athe ngqo TCT Amasuntswana aNgqo

TCT Amasuntswana aNgqo M16 Amasuntswana aNgqo

M16 Amasuntswana aNgqo TCT X Amasuntswana aNgqo

TCT X Amasuntswana aNgqo 45 Isidanga seChamfer Bit

45 Isidanga seChamfer Bit Ukukrola Bit

Ukukrola Bit Bit yeKona

Bit yeKona Amasuntswana omzila wePCD

Amasuntswana omzila wePCD Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander wabona

Edge Bander wabona I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Ezinye izixhobo kunye nezixhobo

Ezinye izixhobo kunye nezixhobo Drill Adapter

Drill Adapter Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Iimela zokucwangcisa

Iimela zokucwangcisa