Yintoni ingxaki nge edge banding?

I-Edgebanding ibhekisa kuyo yomibini inkqubo kunye nomcu wemathiriyeli esetyenziselwa ukudala i-aesthetically please trim ejikeleze imiphetho yeplywood engagqitywanga, ibhodi yamasuntswana, okanye iMDF. I-Edgebanding ikwandisa ukuqina kweeprojekthi ezahlukeneyo ezifana nekhabhinethi kunye ne-countertops, inika ukubonakala okuphezulu, umgangatho ophezulu.

I-Edgebanding ifuna ukuguquguquka ngokwemigaqo ye-adhesive application. Ukushisa kwegumbi, kunye ne-substrate, kuchaphazela ukunamathela. Ekubeni i-edgebanding yenziwe kwizinto ezininzi ezahlukeneyo, kubalulekile ukukhetha i-adhesive enikezela ukuguquguquka kunye nekhono lokukwazi ukudibanisa kwiintlobo ezahlukeneyo ze-substrates.

Iglu eshushu enyibilikayo iyincamathelisi eneenjongo ezininzi esetyenziswa kuluhlu olubanzi lwezicelo kwaye ilungele yonke into ebhantini ephela kuquka iPVC, melamine, ABS, acrylic kunye neveneer yomthi. I-Hot melt ikhethwa kakhulu ngenxa yokuba iyafikeleleka, inokuphinda inyibilike kwakhona, kwaye kulula ukusebenza nayo.Enye yezinto ezingalunganga zokutywinwa kwe-adhesive edge edge eshushu kukuba kukho i-glue seams.

Nangona kunjalo, ukuba i-glue seams ibonakala, mhlawumbi isixhobo asizange sihlanjululwe ngokufanelekileyo. Kukho iindawo ezintathu eziphambili: inxalenye ye-pre-milling cutter, iyunithi ye-rubber roller kunye neyunithi ye-roller yoxinzelelo.

1. Ukungaqhelekanga kwindawo yokusika yangaphambili

-

Ukuba isiseko sesiseko sebhodi esele sifakwe ngaphambili sinemiqolo kwaye iglue isetyenziswe ngokungalingani, iziphene ezifana nemigca yeglue egqithisileyo iya kwenzeka.Indlela yokujonga ukuba i-cutter pre-milling cutter iyinto eqhelekileyo kukucima zonke iiyunithi kwaye uvule kuphela i-cutter pre-milling cutter. Emva kokugaya i-MDF yangaphambili, jonga ukuba umphezulu webhodi usicaba. -

Ukuba ipleyiti e-pre-milled ayilingani, isisombululo kukuyibuyisela endaweni entsha ye-pre-milling cutter.

2. Iyunithi ye-rubber roller ayiqhelekanga.

-

Kunokubakho impazamo kwi-perpendicularity phakathi kwe-roller yokugqoka irabha kunye nesiseko somgangatho weplate. Ungasebenzisa irula yesikwere ukulinganisa i-perpendicularity. -

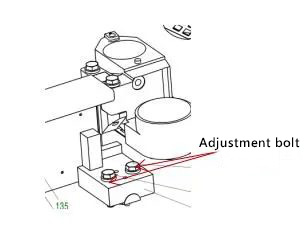

Ukuba impazamo inkulu kune-0.05mm, kuyacetyiswa ukuba utshintshe zonke ii-cutters ze-milling.Xa i-pool yokugubungela i-glue iphantsi kobushushu boshishino, iqondo lokushisa liphezulu njenge-180 ° C kwaye alinakuchukunyiswa ngezandla ezingenanto. Indlela elula yokujonga kukufumana isiqwenga se-MDF, ulungelelanise ubungakanani beglue ubuncinci, kwaye ubone ukuba isiphelo se-glued surface siphezulu naphantsi. Yenza uhlengahlengiso oluncinci ngokulungisa iibholiti ukwenzela ukuba yonke isiphelo sobuso sisetyenziswe ngokulinganayo kunye neyona nto encinci yeglue.

3. Iyunithi yevili loxinzelelo ayiqhelekanga

-

Kukho amanqaku ashiyekileyo eglu kumphezulu wevili loxinzelelo, kwaye umphezulu awulingani, nto leyo eya kubangela impembelelo embi yokucinezela. Kufuneka icocwe ngexesha, kwaye emva koko ukhangele ukuba uxinzelelo lomoya kunye nevili loxinzelelo luqhelekileyo. -

Iimpazamo kwi-verticality yevili lokushicilela nazo ziya kukhokelela ekutywinweni okungalunganga komphetho. Nangona kunjalo, kufuneka uqale uqinisekise ukuba isiseko sebhodi sithe tyaba phambi kokuba ulungelelanise ukuqina kwevili lokushicilela.

Ezinye izinto eziqhelekileyo ezichaphazela umgangatho we-edge banding

1,Ingxaki yeZixhobo

Ngenxa yokuba i-injini yomshini we-edge banding kunye nomzila awukwazi ukusebenzisana kakuhle, umzila awuzinzile ngexesha lokusebenza, ngoko imichilo ye-edge edge ayiyi kuhambelana ngokugqibeleleyo. ukungabikho kweglue okanye i-coat engalinganiyo idla ngokubangelwa yintonga yoxinzelelo lwe-gluing engabambisani kakuhle kunye ne-pad chain chain pad. Ukuba izixhobo zokucheba kunye nezixhobo ze-chamfering azilungelelaniswanga ngokufanelekileyo, kungekhona nje ukufuna umsebenzi ongezelelweyo, kunye nomgangatho wokunciphisa kunzima ukuqinisekisa.

Ngamafutshane, ngenxa yezinga elibi lokuthunyelwa kwezixhobo, ukulungiswa kunye nokugcinwa, iingxaki zomgangatho ziya kuhlala. I-blunt yezixhobo zokusika nazo zichaphazela ngokuthe ngqo umgangatho weephelo kunye nokunciphisa. I-engile yokucheba enikwe sisixhobo iphakathi kwe-0 ~ 30 °, kwaye i-engile yokucheba ekhethiweyo kwimveliso jikelele yi-20 °. I-blunt blade yesixhobo sokusika iya kubangela ukuba umgangatho ophezulu unciphise.

2, uMsebenzi

Umthi owenziwe ngumntu njengento yokusebenzela, ukuphambuka kobunzima kunye nokukhanya akukwazi ukufikelela kwimigangatho. Oku kwenza ukuba umgama ukusuka kumavili e-roller yoxinzelelo ukuya kumphezulu we-conveyor kunzima ukuseta. Ukuba umgama uncinci kakhulu, uya kubangela uxinzelelo oluninzi kwaye uhlukane nemicu kunye ne-workpiece. Ukuba umgama ukhulu kakhulu, ipleyiti ayiyi kunyanzeliswa, kwaye imichilo ayikwazi ukuboshwa ngokuqinileyo ngomphetho.

3, Edge Banding Strips

Imichilo yebhanti yomphetho ininzi yenziwe ngePVC, enokuthi ichaphazeleke kakhulu yindalo. Ebusika, ubunzima bemichilo ye-PVC buya kunyuka obangela ukuba ukunamathela kwiglue kuyancipha. Kwaye ixesha elide lokugcina, umphezulu uya kuguga; amandla okubambelela kwiglue aphantsi. Kwimicu eyenziwe ngephepha enobukhulu obuncinci, ngenxa yokuqina kwayo okuphezulu kunye nobukhulu obuphantsi (obufana ne-0.3mm), iya kubangela ukusika okungalinganiyo, amandla angonelanga okudibanisa, kunye nokusebenza kakubi kokucutha. Ke iingxaki ezinje ngenkunkuma enkulu ye-edge banding strips kunye nezinga eliphezulu lokuphinda lisebenze zinzulu.

I-4, iTemperature yeGumbi kunye neTemperature yoMatshini

Xa iqondo lokushisa langaphakathi liphantsi, i-workpiece idlula kumatshini we-edge banding, ukushisa kwayo akunakunyuswa ngokukhawuleza, kwaye kwangaxeshanye, i-adhesive ipholile ngokukhawuleza okunzima ukugqiba ukudibanisa. Ngoko ke, ukushisa kwangaphakathi kufuneka kulawulwe ngaphezu kwe-15 ° C. Ukuba kuyimfuneko, iinxalenye zomshini we-edge banding zingatshatyalaliswa ngaphambi kokuba zisebenze (i-heater yombane inokongezwa ekuqaleni kwenkqubo yokudibanisa edge). Kwangaxeshanye, ubushushu bokubonisa ubushushu bentonga yoxinzelelo lwegluing kufuneka bulingane okanye buphakame kunobushushu apho i-adhesive eshushu iyanyibilika inokunyibilika ngokupheleleyo.

5,Isantya sokutya

Isantya sokutya koomatshini banamhlanje bebhanti bomphetho ngokuqhelekileyo yi-18 ~ 32m / min. Abanye oomatshini abanesantya esiphezulu banokufikelela kwi-40m / min okanye ngaphezulu, ngelixa umatshini webhanti we-curve edge unesantya sokutya esi-4 ~ 9m / min kuphela. Isantya sokutya somatshini we-automatic edge banding sinokulungelelaniswa ngokwamandla e-edge banding. Ukuba isantya sokutya siphezulu kakhulu, nangona ukusebenza kwemveliso kuphezulu, amandla e-edge banding aphantsi.

Luxanduva lwethu ukuphelisa ibhendi ngokuchanekileyo. Kodwa kuya kufuneka uyazi, kusekho ukhetho ekufuneka ulwenzile xa uvavanya iinketho zebhendi yomda.

Kutheni ukhetha HERO pre-milling cutter?

-

Iyakwazi ukucubungula izinto ezahlukeneyo. Izinto eziphambili zokucubungula ziyibhodi yoxinaniso, ibhodi ye-particle, i-plywood ye-multilayer, i-fiberboard, njl. -

Iblade yenziwe ngezinto zedayimane ezingeniswa kumazwe angaphandle, kwaye kukho inkangeleko egqibeleleyo yoyilo lwamazinyo. -

Iphakheji ezimeleyo kunye nenhle kunye nebhokisi kunye nesiponji ngaphakathi, esinokukhusela ngexesha lokuthutha. -

Isombulula ngokufanelekileyo iziphene zokungahlali ixesha elide kunye nokunxiba okunzulu kwe-carbide cutter. Inokuphucula kakhulu umgangatho wembonakalo yemveliso. Nika ubomi obude bokusebenzisa. -

Akukho mnyama, akukho ukuhlukana komda, ukubonakala okugqibeleleyo koyilo lwamazinyo, ngokuhambelana ngokupheleleyo neteknoloji yokucubungula. -

Sineminyaka engaphezu kwama-20 yamava kwaye sinikezela ngeenkonzo ezipheleleyo zokuthengisa kwangaphambili kunye nasemva kokuthengisa. -

Umgangatho ogqwesileyo wokusika kwizinto ezenziwe ngomthi ezinemicu.

Ixesha lokuposa: Mar-01-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Ubungakanani Saw

HERO Panel Ubungakanani Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade

IQHAWE LOKUQHUBEKA kweenkuni zabona iBlade HERO Aluminiyam Saw

HERO Aluminiyam Saw I-Grooving Saw

I-Grooving Saw Iprofayile yentsimbi yabona

Iprofayile yentsimbi yabona Edge Bander wabona

Edge Bander wabona Saw Acrylic

Saw Acrylic PCD Saw Blade

PCD Saw Blade PCD Ubungakanani beSaw Blade

PCD Ubungakanani beSaw Blade PCD Panel Ubungakanani Saw

PCD Panel Ubungakanani Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminium Saw

PCD Aluminium Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Metal Ferrous

Cold Saw Blade for Metal Ferrous Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Umtshini weSaw obandayo

Umtshini weSaw obandayo Drill Bits

Drill Bits Amasuntswana eDowel Drill

Amasuntswana eDowel Drill Ngokusebenzisa i-Drill Bits

Ngokusebenzisa i-Drill Bits Amasuntswana e-Hinge Drill

Amasuntswana e-Hinge Drill TCT Inyathelo Drill Bits

TCT Inyathelo Drill Bits HSS Drill Bits / Mortise Bits

HSS Drill Bits / Mortise Bits Amasuntswana eRouter

Amasuntswana eRouter Amasuntswana aNgqo

Amasuntswana aNgqo Amasuntswana amade athe ngqo

Amasuntswana amade athe ngqo TCT Amasuntswana aNgqo

TCT Amasuntswana aNgqo M16 Amasuntswana aNgqo

M16 Amasuntswana aNgqo TCT X Amasuntswana aNgqo

TCT X Amasuntswana aNgqo 45 Isidanga seChamfer Bit

45 Isidanga seChamfer Bit Ukukrola Bit

Ukukrola Bit Bit yeKona

Bit yeKona Amasuntswana omzila wePCD

Amasuntswana omzila wePCD Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander wabona

Edge Bander wabona I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Ezinye izixhobo kunye nezixhobo

Ezinye izixhobo kunye nezixhobo Drill Adapter

Drill Adapter Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Iimela zokucwangcisa

Iimela zokucwangcisa