isingeniso

Ekwakhiweni nasekukhiqizeni, amathuluzi okusika abalulekile.

I-Chop Saw, i-Miter Saw kanye ne-Cold Saw imelela amathuluzi okusika amathathu ajwayelekile futhi asebenzayo. Imiklamo yabo eyingqayizivele nezimiso zokusebenza zibenza badlale indima ebalulekile emisebenzini ehlukene yokusika.

Kuphela ngethuluzi lokusika elilungile elikwazi ukuhlinzeka ngokusikeka okunembile nokusheshayo ngaphandle kokuhlanekezela izinto ezibonakalayo kunembile futhi ukusika okusheshayo kungenzeka. I-saw blade emithathu ethandwa kakhulu; ukukhetha phakathi kwabo kungase kube nzima.

Lesi sihloko sizobheka ngokujulile la mathuluzi amathathu okusika, sihlaziye ukufana nokuhluka kwawo, futhi siveze izinzuzo zabo ezinhlelweni ezisebenzayo ukuze sisize abafundi baqonde kangcono indlela yokukhetha ithuluzi lokusika elifanele izidingo zabo zomsebenzi.

Okuqukethwe

-

I-Miter saw

-

Cold saw blade

-

Chop saw

-

Okuhlukile

-

Isiphetho

I-Miter saw

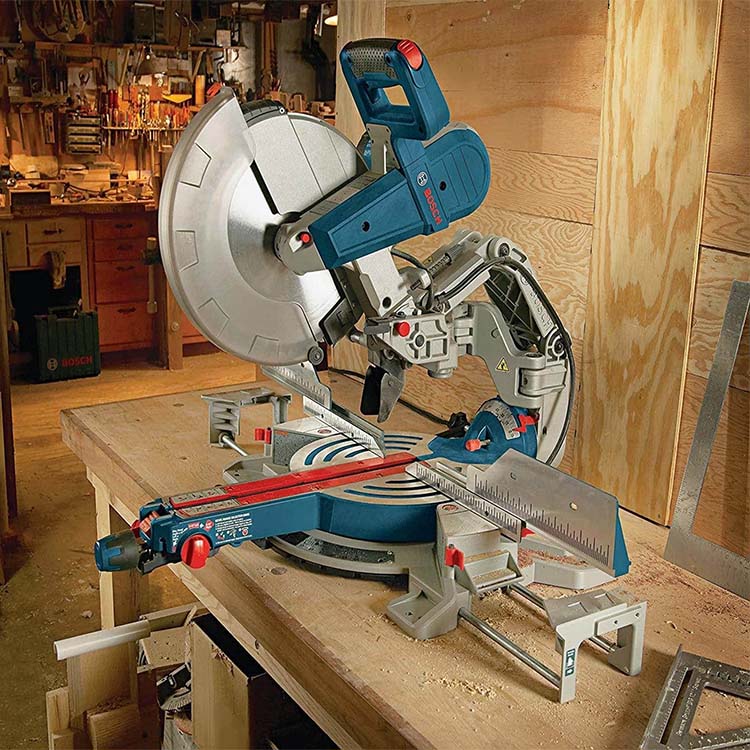

Isaha, eyaziwa nangokuthi i-miter saw, iwuhlobo lwesaha elisetshenziselwa ukwenza ama-crosscut anembile, ama-miter, nama-bevels endaweni yokusebenza. Iqukethe i-blade yesaha eyindilinga ebekwe engalweni eshwibayo ekwazi ukuzungeza ukwenza ukusikeka kwe-miter kuma-engeli ahlukahlukene. Ngokuya ngemodeli, ingakwazi futhi ukwenza ukusikeka kwe-bevel ngokutshekisa i-blade

I-blade idonselwa phansi phezu kwezinto, ngokungafani nesaha eliyindilinga lapho idla khona ngempahla.

Ngokuyinhloko zisetshenziselwa ukusika izinkuni kanye nokubunjwa, kodwa futhi zingasetshenziswa ukusika insimbi, ubucwebe, namapulasitiki, inqobo nje uma kusetshenziswa uhlobo olufanele lweblade ekusikeni.

Usayizi

Amasaha ama-Miter afika ngobukhulu obuhlukahlukene. Amasayizi ajwayelekile kakhulu angama-180, 250 kanye nama-300 mm (7+1⁄4, 10 kanye no-12 in) ama-blades, ngayinye enomthamo wayo wokusika.

Amasaha e-Miter avamise ukuza ngo-250 kanye no-300 mm (10 kanye no-12 in) ekucushweni kosayizi weblade futhi ngokuvamile enziwa nge-carbon steel futhi angase eze ne-coating ukuze enze ukusika kube lula.

Izinyo Ukuma

Ukwakheka kwamazinyo kuza ngezinhlobonhlobo eziningi: i-ATB (i-bevel ephezulu eshintshanayo), i-FTG (i-flat top grind) kanye ne-TCG (i-triple chip grind) yizona ezivame kakhulu. Idizayini ngayinye yenzelwe into ethile kanye nokwelashwa okunqenqemeni.

Ukusetshenziswa

I-saha ivamise ukusetshenziswa nge-Wood, futhi ingatholakala kumamodeli nobukhulu obuhlukahlukene.

Amasaha ama-Miter ayakwazi ukwenza ukusikeka okuqondile, kwe-miter, kanye ne-bevel.

Uhlobo

nali uhla olukhulu lwamasaha ama-miter atholakalayo emakethe. I-bevel eyodwa, i-double bevel, i-sliding, i-compound njll.

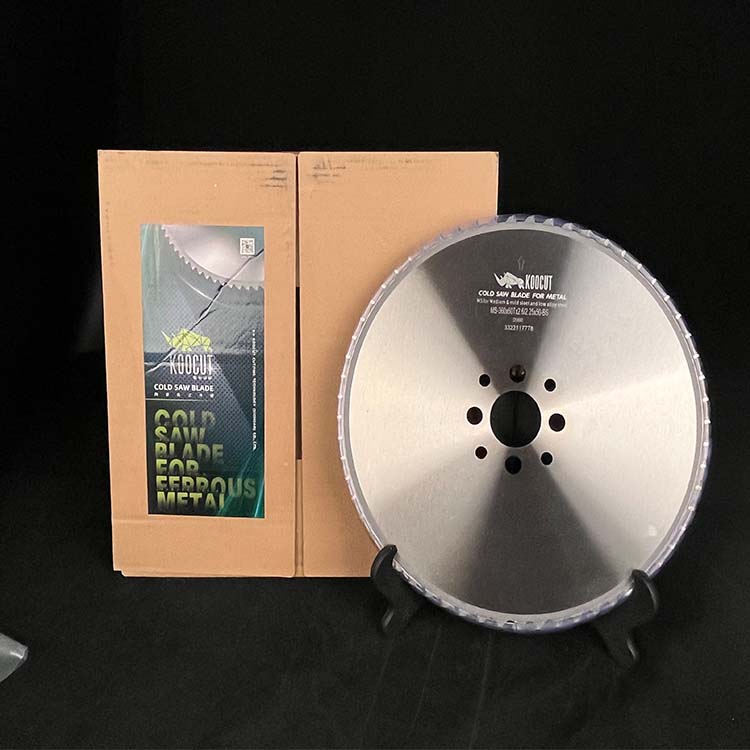

Isaha elibandayo

Aisaha elibandayoiyisaha eliyindilinga eliklanyelwe ukusika insimbi esebenzisa insimbi enamazinyo ukuze idlulise ukushisa okukhiqizwa ngokusika kuma-chips adalwe i-saw blade, okuvumela kokubili i-blade nezinto ezisikwayo ukuze kuhlale kupholile.Lokhu kuphambene nesaha elihuqayo, elihushuza insimbi futhi likhiqize ukushisa okukhulu okumuncwa izinto ezisikwayo kanye ne-saw blade.

Isicelo

Amasaha abandayo ayakwazi ukwenza ama-alloys ayoniyo kakhulu futhi angewona ayoni. Izinzuzo ezengeziwe zifaka ukukhiqizwa okuncane kwama-burr, izinhlansi ezimbalwa, ukuguquguquka okuncane nothuli.

Amasaha aklanyelwe ukusebenzisa isistimu yokupholisa izikhukhula ukuze agcine amazinyo e-saha epholile futhi egcotshiwe angase anciphise izinhlansi nokushintsha kombala ngokuphelele. Uhlobo lwe-saw blade kanye nenani lamazinyo, isivinini sokusika, kanye nezinga lokudla konke kufanele kuhambisane nohlobo nosayizi wezinto ezisikwayo, okufanele ziboshwe ngomshini ukuze kuvinjelwe ukunyakaza ngesikhathi sokusika.

Kodwa kunohlobo oluthile lwesaha elibandayo elingadingi ukupholisa.

Uhlobo

Ama-saha ama-Cermet abandayo

Amasaha Amakhaza Omile

I-Cermet Cold Saw Blade

I-Cermet HSS Cold Saw iwuhlobo lwesaha elisebenzisa izindwani ezenziwe ngensimbi enesivinini esikhulu (HSS), i-carbide, noma i-cermet ukwenza imisebenzi yokusika. Ama-saha abandayo anesihloko se-Cermet aklanyelwe ukusika amabhilidi, amapayipi, nezimo zensimbi ezihlukahlukene. Akhiwe nge-kerf encane futhi aziwa ngokusebenza kwawo okukhethekile kanye nempilo enwetshiwe ye-blade.

Imishini Efanelekayo: Umshini omkhulu wokusaha obandayo

Dry Cut Cold Saw

Amasaha abandayo anqunyiwe ayaziwa ngokunemba kwawo, akhiqiza ukusikeka okuhlanzekile nokungenaburr, okunciphisa isidingo somsebenzi owengeziwe wokuqeda noma wokuqeda. Ukungabikho kokupholisa kubangela indawo yokusebenza ehlanzekile futhi kuqeda ukungcola okuhlobene nezindlela zokusika ezimanzi zendabuko.

Izici ezibalulekile zeamasaha abandayo omilezihlanganisa izindwani zabo eziyindilinga ezinesivinini esikhulu, ezivame ukuhlonywa amazinyo e-carbide noma ama-cermet, aklanyelwe ngokukhethekile ukusika insimbi. Ngokungafani namasaha endabuko abrasive, amasaha abandayo amisiwe asebenza ngaphandle kwesidingo sokupholisa noma ukuthambisa. Le nqubo yokusika okomile inciphisa ukukhiqizwa kokushisa, iqinisekisa ukuthi ubuqotho besakhiwo kanye nezakhiwo zensimbi zihlala zinjalo.

Isaha elibandayo likhiqiza amanxeba okuqeda anembile, ahlanzekile, agayiwe, kuyilapho isaha le-chop lingase lizule futhi likhiphe isiphetho ngokuvamile esidinga ukuhlinzwa okulandelayo ukuze kukhishwe isikwele kanye nesikwele ngemva kokuba into isipholile. Ukusikeka kwamasaha abandayo ngokuvamile kungase kwehliswe emugqeni ngaphandle kokudinga ukuhlinzwa okuhlukile, okonga imali.

Imishini efanelekayo: I-Metal Cold Cutting Saw

Nakuba isaha elibandayo lingajabulisi kangako njengesaha le-chop, likhiqiza ukusika okubushelelezi okukuvumela ukuba uqedele umsebenzi ngokushesha. Akusadingeki ukuthi ulinde ukuthi impahla yakho iphole ngemva kokusikwa.

Chop saw

Amasaha abrasive uhlobo lwethuluzi lamandla elisebenzisa amadiski abrasive noma izindwani ukusika izinto ezihlukahlukene, njengezinsimbi, izitsha zobumba, nokhonkolo. Amasaha abrasive aziwa nangokuthi amasaha asikiwe, amasaha ensimbi, noma amasaha ensimbi.

Amasaha abrasive asebenza ngokuzungezisa i-abrasive disc noma iblade ngesivinini esikhulu futhi afake ukucindezela kokubalulekile okufanele kusikwe. Izinhlayiya ezilumayo kudiski noma i-blade ziguga okokusebenza futhi zenze ukusika okubushelelezi nokuhlanzekile.

Usayizi

Idiski yokusika ivamise ukuba ngu-14 ku-(360 mm) ububanzi kanye no-764 ku-(2.8 mm) ukujiya. Amasaha amakhudlwana angasebenzisa ama-disc anobubanzi obuyi-16 in (410 mm).

Okuhlukile

Izindlela zokusika:

Isaha elibandayo,Amasaha enza izinqamuleli eziqondile kuphela.

Amasaha ama-Miter ayakwazi ukwenza ukusikeka okuqondile, kwe-miter, kanye ne-bevel.

Igama elingalungile elivamile ngezinye izikhathi elisetshenziselwa ukubhekisela ku-miter saw i-chop saw. Nakuba zifana ngendlela ethile esenzweni sazo sokusika, ziyizinhlobo ezimbili ezihluke ngokuphelele zesaha. I-chop saw ihloselwe ukusika insimbi futhi ivamise ukusetshenziswa ngenkathi ibekwe yacaba phansi ngeblade emiswe ku-90° mpo. Isaha le-chop alikwazi ukusika i-miter ngaphandle kwalapho lisetshenziswe opharetha ngokuphambene nomsebenzi womshini ngokwawo.

Isicelo

Isaha lesigqoko lilungele ukusika izinkuni.

Ngokungafani namasaha etafula namasaha ebhande, zinhle kakhulu uma kuziwa endabeni yokusika njengamapulangwe anobukhulu bokufola, ukudeka, noma ukubeka phansi.

Isaha elibandayo nelokusika elokusika insimbi, kodwa isaha elibandayo lingasika Izinhlobonhlobo zezinto ezisetshenziswayo kunesaha lokusika.

Futhi ukusika kuyashesha kakhulu

Isiphetho

Njengethuluzi lokusika eliguquguqukayo nelisebenzayo,i-Chop Sawuyaphumelela ekusikeni ngokuqondile izinhlobonhlobo zezinto. Isakhiwo sayo esilula kodwa esinamandla siyenza isetshenziswe kabanzi ezindaweni zokwakha nakwezinye izimo.

I-Miter Saw'sukuguquguquka ekulungiseni i-engeli kanye nokusika kwe-bevel kuyinzuzo ephawulekayo, okwenza kube ilungele umsebenzi wokwenza izinkuni nokuhlobisa. Idizayini yayo ivumela abasebenzisi ukuthi benze kalula ama-engeli ahlukahlukene kanye nokusikeka kwe-bevel.

I-Cold Sawiyingqayizivele emkhakheni wokusika insimbi ngobuchwepheshe bayo bokusika obubandayo. Ukusetshenziswa kobuchwepheshe bokusika okubandayo akugcini nje ukwandisa isivinini sokusika, kodwa futhi kuqinisekisa imiphumela yokusika ephezulu, efanelekile ikakhulukazi izigcawu ezidinga ukusebenza okuphezulu kwezinto ezibonakalayo.

Uma unentshisekelo, singakunikeza amathuluzi angcono kakhulu.

Isikhathi sokuthumela: Dec-30-2023

I-TCT Saw Blade

I-TCT Saw Blade IQHAWE Sizing Saw Blade

IQHAWE Sizing Saw Blade I-HERO Panel Sizing Saw

I-HERO Panel Sizing Saw IQHAWE Lokushaya I-Saw Blade

IQHAWE Lokushaya I-Saw Blade IQHAWE Eliqinile Izinkuni Saw Blade

IQHAWE Eliqinile Izinkuni Saw Blade IQHAWE Aluminium Saw

IQHAWE Aluminium Saw I-Grooving Saw

I-Grooving Saw Iphrofayili Yensimbi Yabona

Iphrofayili Yensimbi Yabona I-Edge Bander Saw

I-Edge Bander Saw I-Acrylic Saw

I-Acrylic Saw I-PCD Saw Blade

I-PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade I-PCD Panel Sizing Saw

I-PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade I-PCD Grooving Saw

I-PCD Grooving Saw I-PCD Aluminium Saw

I-PCD Aluminium Saw I-PCD Fiberboard Saw

I-PCD Fiberboard Saw I-Cold Saw Yensimbi

I-Cold Saw Yensimbi Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal I-Dry Cut Saw Blade ye-Ferrous Metal

I-Dry Cut Saw Blade ye-Ferrous Metal Cold Saw Machine

Cold Saw Machine I-Drill Bits

I-Drill Bits Izingcezu ze-Dowel Drill

Izingcezu ze-Dowel Drill Nge-Drill Bits

Nge-Drill Bits Ama-Hinge Drill Bits

Ama-Hinge Drill Bits TCT Isinyathelo Drill Bits

TCT Isinyathelo Drill Bits HSS Drill Bits/Mortise Bits

HSS Drill Bits/Mortise Bits Ama-router Bits

Ama-router Bits Amabhithi Aqondile

Amabhithi Aqondile Izingcezu Ezinde Eziqondile

Izingcezu Ezinde Eziqondile Amabhithi Aqondile we-TCT

Amabhithi Aqondile we-TCT I-M16 Amabhithi Aqondile

I-M16 Amabhithi Aqondile I-TCT X Amabhithi Aqondile

I-TCT X Amabhithi Aqondile 45 Degree Chamfer Bit

45 Degree Chamfer Bit I-Carving Bit

I-Carving Bit I-Corner Round Bit

I-Corner Round Bit I-PCD Router Bits

I-PCD Router Bits Edge Banding Amathuluzi

Edge Banding Amathuluzi I-TCT Fine Trimming Cutter

I-TCT Fine Trimming Cutter I-TCT Pre Milling Cutter

I-TCT Pre Milling Cutter I-Edge Bander Saw

I-Edge Bander Saw I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter I-PCD Pre Milling Cutter

I-PCD Pre Milling Cutter I-PCD Edge Bander Saw

I-PCD Edge Bander Saw Amanye Amathuluzi Nezesekeli

Amanye Amathuluzi Nezesekeli I-Drill Adapter

I-Drill Adapter Drill Chucks

Drill Chucks Isondo Lesanti Ledayimane

Isondo Lesanti Ledayimane Imimese Yokuhlela

Imimese Yokuhlela