Mayelana nokusika insimbi, sinamathuluzi amaningi okusikwa. Kodwa ingabe uyawazi ngempela umehluko phakathi kwakho?

Nalu olunye ulwazi ongeke ukwazi ukulugeja!

Okuqukethwe

-

I-Cold Saw Basics

-

Ukuqhathanisa namasondo okugaya endabuko kanye nedatha yokusika

-

I-FAQ mayelana nokusetshenziswa kwe-Cold Saw kanye nokufakwa

-

Isiphetho

I-Cold Saw Basics

I-Cold sawing, noma i-sawing yensimbi ebandayo, isifinyezo senqubo yokusaha yemishini yokusaha eyindilinga yensimbi. Enqubweni yokusaha insimbi, ukushisa okukhiqizwa lapho i-saw blade isaha i-workpiece idluliselwa ku-sawdust ngamazinyo asaha, futhi ucezu olusaha kanye ne-saw blade kugcinwa kupholile, ngakho kubizwa ngokuthi i-cold saw.

1. I-Cold Saw Cutting Izici

Ukunemba okuphezulu kwe-workpiece, ukugoqa okuhle kwendawo, ukunciphisa ngempumelelo ukuqina kokucubungula kwenqubo elandelayo;

Fast processing speed, ngempumelelo ngcono ukukhiqiza ukusebenza kahle;

Izinga eliphakeme lokuzenzakalelayo, umuntu oyedwa angasebenzisa imishini eminingi, ehlise ngempumelelo izindleko zabasebenzi;

I-workpiece ngeke ikhiqize ukuguquguquka kanye nezinguquko zenhlangano yangaphakathi;

Inqubo yokusaha incane ngezinhlansi, uthuli nomsindo.

2: Injongo Yokusaha

Inhloso yokusaha ukufeza umphumela wokusaha wekhwalithi ephezulu

Khona-ke ngokusekelwe ezimisweni ezingenhla, singadweba ifomula.

Umphumela omuhle wokusaha = imishini yokusaha ehambisanayo + yekhwalithi ephezulu ye-saw blade + amapharamitha alungile wohlelo lokusaha

Kuya ngale fomula, ukuze sikwazi ukulawula umphumela wokusaha kusukela kusici esingu-3.

3: Isaha elibandayo lensimbi - Izinto ezijwayelekile zokucubungula

Izinto zokusika ezicutshungulwayo:

Insimbi yesiteshi, i-I-beam, ibha yensimbi eyindilinga, ipayipi lensimbi, ingxube ye-aluminium

Izinto zokusika ezingalungiseki:

Insimbi engagqwali (idinga i-saw blade ekhethekile) Insimbi yensimbi Ecishiwe futhi eqinile

Lezi ezinye izinto ezivamile ezingasikwa nalezo ezingenakunqunywa

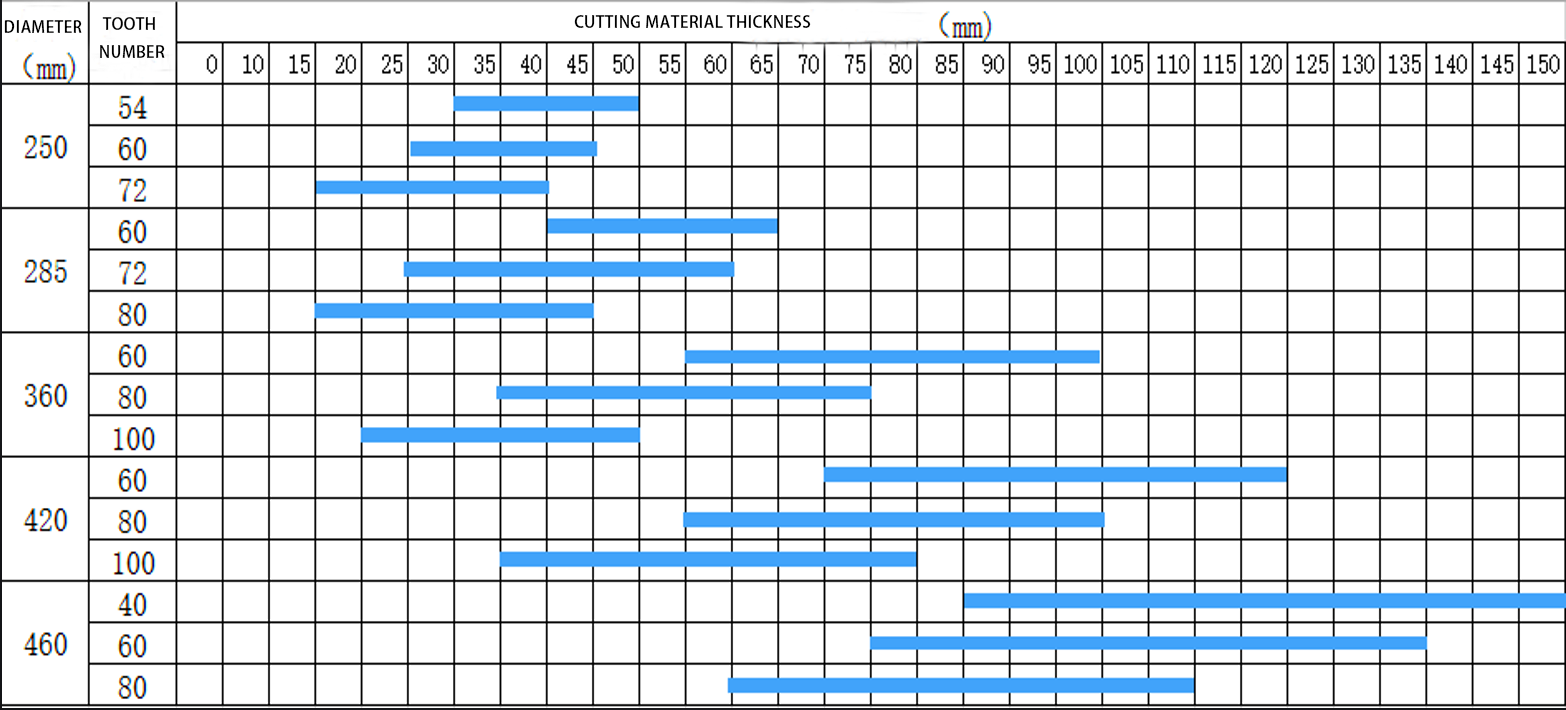

Ngasikhathi sinye, ukukhethwa kosayizi wezinsimbi ezibandayo zensimbi nakho kudinga ukususelwa kubukhulu bezinto zokusika.

Njengasethebulani elingezansi.

Ukuqhathanisa namasondo okugaya endabuko kanye nedatha yokusika

Ukugaya Wheel Disc

I-cutting disc ingeyesondo lokugaya. Yenziwe nge-abrasive kanye ne-binder resin yokusika insimbi evamile, insimbi engagqwali kanye nezinto ezingezona ezensimbi. Ihlukaniswe nge-resin cutting disc kanye ne-diamond cutting disc.

Isebenzisa i-glass fibre kanye ne-resin njengezinto zokubopha eziqinisiwe, inamandla aphezulu, umthelela namandla okugoba, futhi isetshenziswa kabanzi ekukhiqizeni nasekuvaleni kwensimbi evamile, insimbi engagqwali kanye nokungeyona insimbi.

Kodwa amasondo okugaya asetshenziswa abantu. Kukhona ukushiyeka okungenakuzitshwa.

Amasaha abandayo okusika insimbi axazulula la maphuzu obuhlungu kahle kakhulu.

Ngokulandelayo, sizoxoxa ngezindaba ezilandelayo.

1 Ukuphepha

Idiski yesondo lokugaya: ingozi yokuphepha engaba khona. Ama-opharetha angahogela inqwaba yezinhlayiya ezivela kudiski lesondo lokugaya ngesikhathi sokusika, okubangela izinkinga zempilo kanye nokubeka izingozi zomlilo. Izinto zokusika zivame ukuba nezinhlansi ezinkulu.

Ngesikhathi esifanayo, ishidi lokugaya liphuka kalula, kubangela ingozi efihliwe yokuphepha kwabasebenzi.

Amasondo okugaya ekukhiqizeni kufanele abe nekhwalithi ezinzile futhi angabi nasici, ngoba noma yikuphi ukuphuka kwe-saha blade kungase kubangelwe ukukhubazeka okuncane. Uma iphukile, izodala ukulimala kubantu.

Phakathi nenqubo yokusika, kuyadingeka ukuthi uhlale unake ukuthi kukhona ukubunjwa okungavamile noma imifantu. Uma kukhona noma yisiphi isimo, kuyadingeka ukuyeka ukusebenzisa bese ushintsha isondo lokugaya ngokushesha.

Isaha elibandayo: alukho uthuli kanye nezinhlansi ezincane ngesikhathi sokusika. Ingozi yokuphepha incane. Abasebenzisi bangayisebenzisa ngokuzethemba. Ngesikhathi esifanayo, ikhwalithi nokuqina kwamasaha abandayo kuthuthukiswa kakhulu uma kuqhathaniswa namasondo okugaya.

Impilo yokusika yinde kakhulu kunaleyo yamadiski okugaya.

2 Ukusika Ikhwalithi

Ukusebenza kahle kwe-grinding wheel cutting disc kuphansi, futhi ngokuvamile kudinga ukusikeka okuningi ukuze kuqedelwe umsebenzi. Ngaphezu kwalokho, ukunemba kokusika kwesondo lokugaya kuncane kakhulu, futhi kunzima ukuhlangabezana nezidingo zokusika okuphezulu.

Ukusebenza kahle kokucubungula kuphansi, izindleko zizonke ziphezulu, futhi amandla okusebenza omqhubi aphakeme ngenxa yokujikeleza kwesondo elicutshungulwayo elicutshungulwayo kanye nesitsha sokusika, esidala uthuli oluningi nomsindo.

Ingxenye ephambanayo yezinto zokusika ishintshile futhi inobucaba obumpofu.

Ngokuvamile, amazinyo ambalwa inkaba enawo, yilapho izosika khona ngokushesha, kodwa futhi ukusika kuyaqina. Uma ufuna ukuhlanza, ukusika okunembe kakhudlwana, kufanele ukhethe i-blade enamazinyo amaningi.

I-Cold Saw Blade:

Ukusika okubandayo: Izinga lokushisa elikhiqizwa ngesikhathi sokusaha okubandayo kwensimbi liphansi, okunciphisa ukuwohloka kokushisa endaweni yokusika kanye nokuqina kwempahla.

Ama-Smooth Cuts: Uma kuqhathaniswa nezindlela zendabuko zokusika ezishisayo, amasaha abandayo ensimbi akhiqiza ukusikeka okuthambile, okunciphisa isidingo sokucubungula okulandelayo.

Ukunemba: Ngenxa yokusetshenziswa kobuchwepheshe bokusika okubandayo, amasaha abandayo ensimbi anganikeza izilinganiso zokusika eziqondile kanye nezindawo zokusika eziyisicaba.

Ukusika okuphumelelayo: Amasaha abandayo ensimbi angasika ngokushesha ngamasaha ajikelezayo anesivinini esikhulu ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza. Lokhu kwenza amasaha abandayo abe ngcono kakhulu ezimeni ezifana nokukhiqizwa kwevolumu ephezulu kanye nokudiliva okuphuthumayo okudingeka kwenziwe ngokushesha.

Ukusaha okubandayo nakho kunokusetshenziswa kwamandla okuphansi kanye nokungcoliswa kwemvelo. Ngenxa yokuthi amasaha abandayo asebenzisa izinto zokugcoba ukuze anciphise ukushisa, adla amandla amancane kunamasaha ashisayo. Ngesikhathi esifanayo, inqubo yokusika i-saha ebandayo ngeke ikhiqize umusi ocacile namagesi ayingozi, okunciphisa ukungcoliswa kwemvelo.

Izinto zokusika, isigaba siyisicaba, siqondile ngaphandle kwama-burrs.

Sebenzisa izinto zekhwalithi ephezulu, ukumelana nomthelela, akukho ukuqhekeka kwamazinyo

3:Ukusika idatha

I-Flat Steel 1cm * 8cm, imizuzwana engu-6 Iphethe insimbi engu-6cm, imizuzwana engu-11

Insimbi yesikwele 2cm*4cm, imizuzwana emi-3Ububanzi buyi-3.2 cml,3 imizuzwana

I-Round Steel 5cm, imizuzwana eyi-10

Cold saw bladekuthatha kuphela imizuzwana eyi-10 ukucubungula insimbi eyindilinga engu-50mm.

Idiski yokusika isondo lokugaya ithatha amasekhondi angaphezu kwangu-50 ukucubungula insimbi eyindilinga engama-50, futhi ukumelana kuya ngokuya kuba kukhulu.

I-FAQ mayelana nokusetshenziswa kwe-Cold Saw kanye nokufakwa

FAQ

1:I-saw blade ihlehlisiwe. Asikho isidingo sokuqondisa isondo lokugaya, futhi isaha elibandayo elibandayo alikwazi ukusetshenziswa ngokuhlehla.

2: Imishini iqala ukusika ngaphambi kokufinyelela isivinini sokusebenza.

3: Ukusika ngaphandle kokubopha ucezu lokusebenzela noma eminye imisebenzi engekho emthethweni yokulungisa isiqeshana sokusebenza ngokungafanele.

4: Yisebenzise ngesivinini esingalingani uma usaha, okuholela emiphumeleni ye-cross-section engagculisi.

I-5: Uma ubukhali bokusika bungenele, susa isaha ngesikhathi, lilungise, futhi welule impilo yokusika.

Izidingo Zokufaka I-Saw Blade

-

I-saw blade kufanele iphathwe ngokucophelela futhi akufanele ishayisane nezinto zangaphandle ukugwema ukulimala onqenqemeni lwe-blade noma ukuguqulwa komzimba we-saw blade. -

Ngaphambi kokufaka i-saw blade, kufanele uqinisekise ukuthi ama-flange angaphakathi nangaphandle emishini ayigugi futhi ayinamaqhubu ukuze kuqinisekiswe ukucaba kwawo. -

Qinisekisa futhi ulungise isimo sokuguga sebhulashi lezintambo. Uma ukuguga kudlulele, kushintshe kusenesikhathi (ibhulashi locingo lidlala indima ebalulekile ekukhishweni kwe-chip). -

Hlanza amabala kawoyela namafayili ensimbi emakhoneni ensimbi yokuphotha, ibhulashi locingo, i-clamping block, i-flange kanye nekhava yokuzivikela ukuze uqinisekise ukuthi akukho lutho lwangaphandle olusalayo. -

Ngemuva kokufaka i-saw blade nangaphambi kokuqinisa izikulufu, qinisa i-blade yesaha ngakolunye uhlangothi ukuze ukhiphe igebe phakathi kwembobo yokumisa kanye nephinikhodi yokumisa futhi ugweme ukuthi i-blade yesaha. -

Ngemuva kokuqinisekisa ukuthi i-nati ikhiyiwe, vala isembozo somshini, vula inkinobho yokujova uphethiloli (inani lamafutha kufanele lanele), lingasebenzi cishe imizuzu emi-2, misa umshini bese uhlola ukuthi kukhona yini imihuzuko noma ukushisa ebusweni be-saw blade. Ukukhiqizwa okuvamile kungenziwa kuphela uma kungekho okungavamile. -

Khetha imingcele yokusika enengqondo ngokusekelwe ezicini zezinto okufanele zisikwe. Empeleni, ngezinto okunzima ukuzisika, ijubane lokusaha kanye nesivinini sokuphakela akufanele kube ngokweqile. -

Uma usaha, yahlulela ukuthi ukusaha kuyinto evamile yini ngokubheka umsindo wokusaha, ukusika kwento, kanye nokuma kokugoqa kwezinhlamvu zensimbi. -

Lapho usika nge-saw blade entsha, ukuze kuqinisekiswe ukuzinza kwe-saw blade, imingcele yokusika ingancishiswa ifike cishe ku-80% wejubane elivamile ngesikhathi sokusika kokuqala (okubizwa ngokuthi ithuluzi eligijima esiteji), futhi i-sawing ibuyela ekuboneni okujwayelekile ngemva kwesikhathi esithile. ukusika isivinini.

Isiphetho

Ukucutshungulwa kwensimbi kuyindlela yokucubungula enzima emkhakheni wokusaha. Ngenxa yezimpawu zemikhiqizo ecutshunguliwe, izidingo eziphakeme kanye namazinga aphezulu anqunywa ukuklama, ukukhiqizwa nokusetshenziswa kwama-saw blades.

Uma kuqhathaniswa nama-saw blades adlule, isaha elibandayo lizixazulule kahle ezinye izinkinga, kanye nokusebenza kwayo okuphezulu kokusika.

I-Cold saw iwumkhiqizo othrendayo ekucutshungulweni kwensimbi nasekusikeni esikhathini esizayo.

Sihlala sikulungele ukukunikeza amathuluzi okusika alungile.

Njengomphakeli wamasaha ayindilinga, sinikezela ngezimpahla zeprimiyamu, iseluleko somkhiqizo, isevisi yobungcweti, kanye nenani elihle nokusekelwa okukhethekile ngemva kokuthengisa!

Ku-https://www.koocut.com/.

Yeqa umkhawulo bese uya phambili ngesibindi! Isiqubulo sethu.

Isikhathi sokuthumela: Sep-01-2023

I-TCT Saw Blade

I-TCT Saw Blade IQHAWE Sizing Saw Blade

IQHAWE Sizing Saw Blade I-HERO Panel Sizing Saw

I-HERO Panel Sizing Saw IQHAWE Lokushaya I-Saw Blade

IQHAWE Lokushaya I-Saw Blade IQHAWE Eliqinile Izinkuni Saw Blade

IQHAWE Eliqinile Izinkuni Saw Blade IQHAWE Aluminium Saw

IQHAWE Aluminium Saw I-Grooving Saw

I-Grooving Saw Iphrofayili Yensimbi Yabona

Iphrofayili Yensimbi Yabona I-Edge Bander Saw

I-Edge Bander Saw I-Acrylic Saw

I-Acrylic Saw I-PCD Saw Blade

I-PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade I-PCD Panel Sizing Saw

I-PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade I-PCD Grooving Saw

I-PCD Grooving Saw I-PCD Aluminium Saw

I-PCD Aluminium Saw I-PCD Fiberboard Saw

I-PCD Fiberboard Saw I-Cold Saw Yensimbi

I-Cold Saw Yensimbi Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal I-Dry Cut Saw Blade ye-Ferrous Metal

I-Dry Cut Saw Blade ye-Ferrous Metal Cold Saw Machine

Cold Saw Machine I-Drill Bits

I-Drill Bits Izingcezu ze-Dowel Drill

Izingcezu ze-Dowel Drill Nge-Drill Bits

Nge-Drill Bits Ama-Hinge Drill Bits

Ama-Hinge Drill Bits TCT Isinyathelo Drill Bits

TCT Isinyathelo Drill Bits HSS Drill Bits/Mortise Bits

HSS Drill Bits/Mortise Bits Ama-router Bits

Ama-router Bits Amabhithi Aqondile

Amabhithi Aqondile Izingcezu Ezinde Eziqondile

Izingcezu Ezinde Eziqondile Amabhithi Aqondile we-TCT

Amabhithi Aqondile we-TCT I-M16 Amabhithi Aqondile

I-M16 Amabhithi Aqondile I-TCT X Amabhithi Aqondile

I-TCT X Amabhithi Aqondile 45 Degree Chamfer Bit

45 Degree Chamfer Bit I-Carving Bit

I-Carving Bit I-Corner Round Bit

I-Corner Round Bit I-PCD Router Bits

I-PCD Router Bits Edge Banding Amathuluzi

Edge Banding Amathuluzi I-TCT Fine Trimming Cutter

I-TCT Fine Trimming Cutter I-TCT Pre Milling Cutter

I-TCT Pre Milling Cutter I-Edge Bander Saw

I-Edge Bander Saw I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter I-PCD Pre Milling Cutter

I-PCD Pre Milling Cutter I-PCD Edge Bander Saw

I-PCD Edge Bander Saw Amanye Amathuluzi Nezesekeli

Amanye Amathuluzi Nezesekeli I-Drill Adapter

I-Drill Adapter Drill Chucks

Drill Chucks Isondo Lesanti Ledayimane

Isondo Lesanti Ledayimane Imimese Yokuhlela

Imimese Yokuhlela