Yiziphi izinkinga ngokusika i-aluminium?

I-alu alloy ibhekisela "entweni eyinhlanganisela" ehlanganisa insimbi ye-aluminium nezinye izakhi ukuze kuthuthukiswe izici zokusebenza. Ezinye izakhi eziningi zihlanganisa ithusi, i-silicon ye-magnesium noma i-zinc, ukusho nje ezimbalwa.

Ama-alloys e-aluminium anezakhiwo ezihlukile ezihlanganisa ukumelana nokugqwala okungcono, amandla athuthukisiwe nokuqina, ukusho nje ezimbalwa.

I-Aluminium itholakala ngenani lama-alloys ahlukene futhi uchungechunge ngalunye lungase lube nokufutheka okuningana okuhlukile ongakhetha kukho. Ngenxa yalokho, amanye ama-alloys angase abe lula kakhulu ukuwagaya, ukubumba noma ukusika kunabanye. Kubalulekile ukuba nokuqonda okuphelele "kokusebenza" kwe-alloy ngayinye, ngoba zinezakhiwo ezahlukene.

Lokhu kuthola ukusetshenziswa ezinhlobonhlobo zezimboni, ezihlanganisa ezezimoto, ezasolwandle, ezokwakha, nezikagesi.

Kodwa-ke, ukusika nokugaya i-aluminium ngempumelelo nangempumelelo kungaba inselele ngezizathu ezimbalwa. I-Aluminium iyinsimbi ethambile enephuzu elincibilikayo eliphansi kunezinye izinto, njengensimbi. Lezi zici zingaholela ekulayisheni, ekugubheni noma ekushintsheni kokushisa lapho kusika futhi kugaywa impahla.

I-Aluminium ithambile ngokwemvelo futhi kungaba nzima ukusebenza ngayo. Eqinisweni, ingase yakhe i-gummy buildup lapho isikwa noma yenziwa ngomshini. Lokhu kungenxa yokuthi i-aluminium inezinga lokushisa eliphansi lokuncibilika. Lokhu kushisa kuphansi ngokwanele ukuthi ngokuvamile kuzohlangana onqenqemeni lokusika ngenxa yokushisa kokungqubuzana.

Akukho okungathatha indawo yesipiliyoni uma kuziwa ekusebenzeni nge-aluminium. Isibonelo, i-2024 ayinzima kakhulu ukusebenza nayo, kodwa cishe akunakwenzeka ukuyishisela. Ingxubevange ngayinye inezakhiwo ezinikeza izinzuzo kwezinye izinhlelo zokusebenza kodwa ingaba yingozi kwezinye.

UKUKHETHA UMKHIQIZO OLUNGILE WE-ALUMINIUM

Mhlawumbe into ebaluleke kakhulu okufanele icatshangelwe nge-aluminium machining yi-machinist. Ukuqonda izakhiwo ze-aluminium kubalulekile kodwa kanjalo nokukhetha amathuluzi afanele kanye nokwazi ukuthi ungasetha kanjani imingcele yenqubo yokwenza imishini. Ngisho nezindlela zokwenza imishini ye-CNC, umuntu kufanele acabangele izinto eziningi noma ungagcina usunenqwaba yezinto ezilahliwe, futhi lokhu kungase kuthathe noma iyiphi inzuzo oyenzayo emsebenzini.

Kunamathuluzi amaningi nemikhiqizo etholakalayo yokusika, ukugaya nokuqedela i-aluminium, ngayinye inezinzuzo kanye nokubi. Ukwenza ukhetho olufanele lohlelo lokusebenza kungasiza izinkampani zithole ikhwalithi engcono, ukuphepha, kanye nokukhiqiza, kuyilapho futhi kunciphisa isikhathi sokuphumula nezindleko zomsebenzi.

Lapho wenza i-aluminium, udinga isivinini esikhulu sokusika ukuze uthole imiphumela engcono kakhulu. Ngaphezu kwalokho, imiphetho yokusika kufanele ibe nzima futhi ibukhali kakhulu. Lolu hlobo lwemishini ekhethekile lungamela ukutshalwa kwezimali okukhulu esitolo semishini ngesabelomali esilinganiselwe. Lezi zindleko zikwenza kube ukuhlakanipha ukuthembela kuchwepheshe bemishini ye-aluminium kumaphrojekthi akho.

Ukuhlaziya kanye nezixazululo zezinkinga zomsindo ongajwayelekile

-

Uma kunomsindo ongavamile lapho i-saw blade isika i-aluminium, kungenzeka ukuthi i-saw blade ikhubazekile kancane ngenxa yezici zangaphandle noma amandla angaphandle amaningi, ngaleyo ndlela kubangele isixwayiso.

-

Isixazululo: Linganisa kabusha i-carbide saw blade.

-

I-shaft clearance enkulu yomshini wokusika i-aluminium inkulu kakhulu, ibangela ukugxuma noma ukuchezuka.

-

Isixazululo: Misa okokusebenza bese uhlola ukuze ubone ukuthi ukuyifaka kulungile yini.

-

Kukhona okungavamile esisekelweni se-saha blade, njengokuqhekeka, ukuvaleka kanye nokuhlanekezelwa kwemigqa/izimbobo zokuthulisa, okunamathiselwe okumise okukhethekile, nezinye izinto ngaphandle kwezinto zokusika ezihlangabezane nazo ngesikhathi sokusika.

-

Isixazululo: Thola inkinga kuqala bese uyisingatha ngendlela efanele ngokusekelwe kwizimbangela ezahlukene.

Umsindo ongavamile we-saha blade obangelwa ukudla okungavamile

-

Imbangela evamile yale nkinga ukushelela kwe-carbide saw blade.

-

Isixazululo: Lungisa i-saw blade

-

I-shaft eyinhloko yomshini wokusika i-aluminium ibanjiwe

-

Isixazululo: Lungisa i-spindle ngokwesimo sangempela

-

Amafayili ensimbi ngemva kokusaha avimbelwe phakathi kwendlela yokusaha noma phambi kwempahla.

-

Isixazululo: Hlanza amafayili ensimbi ngemva kokusaha ngesikhathi

I-workpiece esahed inokwakheka noma ama-burrs amaningi.

-

Lesi simo ngokuvamile sibangelwa ukuphathwa okungalungile kwe-carbide saw blade ngokwayo noma i-saw blade idinga ukushintshwa, isibonelo: umphumela we-matrix awufanelekile, njll.

-

Isixazululo: Faka esikhundleni i-saw blade noma ulungise kabusha i-saw blade

-

Ukugaya ohlangothini olungagculisi lwezingxenye ze-sawtooth kubangela ukunemba okwanele.

-

Isixazululo: Shintsha i-saw blade noma uyibuyisele kumenzi ukuze igaywe kabusha.

-

I-carbide chip ilahlekelwe amazinyo noma inamathele emigodini yensimbi.

-

Isixazululo: Uma amazinyo elahlekile, i-saw blade kufanele ishintshwe futhi ibuyiselwe kumkhiqizi ukuze ishintshwe. Uma kungamafayili ensimbi, vele uwahlanze.

IMICABANGO YOKUGCINA

Ngenxa yokuthi i-aluminium ithambile kakhulu futhi ayithetheleli kakhulu kunensimbi - futhi ibiza kakhulu - kubalulekile ukulalelisisa lapho usika, ugaya noma uqeda impahla. Khumbula ukuthi i-aluminium ingonakaliswa kalula ngezenzo ezinolaka kakhulu. Abantu bavame ukukala ukuthi ungakanani umsebenzi owenziwa ngezinhlansi abazibonayo. Khumbula, ukusika nokugaya i-aluminium akukhiqizi izinhlansi, ngakho-ke kungaba nzima ukusho uma umkhiqizo ungasebenzi ngendlela efanele. Hlola umkhiqizo ngemuva kokusika nokugaya futhi ubheke amadiphozithi amakhulu e-aluminium, uqaphele kakhulu inani lezinto ezikhishwayo. Ukusebenzisa ingcindezi efanele kanye nokunciphisa ukushisa okukhiqizwa kule nqubo kusiza ukubhekana nezinselele ezivezwayo lapho usebenza nge-aluminium.

Kubalulekile futhi ukukhetha umkhiqizo ofanele wohlelo lokusebenza. Bheka imikhiqizo yekhwalithi ephezulu, engangcolisi edizayinelwe ukusetshenziswa ne-aluminium. Umkhiqizo olungile ohambisana nezinqubo ezihamba phambili ezibalulekile ungasiza ekukhiqizeni imiphumela yekhwalithi, kuyilapho kuncishiswa isikhathi nemali echithwa ekusetshenzweni kabusha nezinto ezilahliwe.

Kungani Khetha i-HERO Aluminium alloy cutting saw blade?

-

I-JAPAN Ithekelisa IGLUE EDAMPING -

Ukudlidliza kanye nokunciphisa umsindo, imishini yokuvikela. -

I-sealanti yasekuqaleni yase-Japan ekwazi ukumelana nokushisa okuphezulu igcwaliswa ukukhulisa i-coefficient encibilikayo, inciphise ukudlidliza nokungqubuzana kwensingo, futhi yandise isikhathi sokuphila se-saha. Ngesikhathi esifanayo, ingagwema ngokuphumelelayo ukukhala futhi yelule isikhathi sokusebenza kwemishini. -

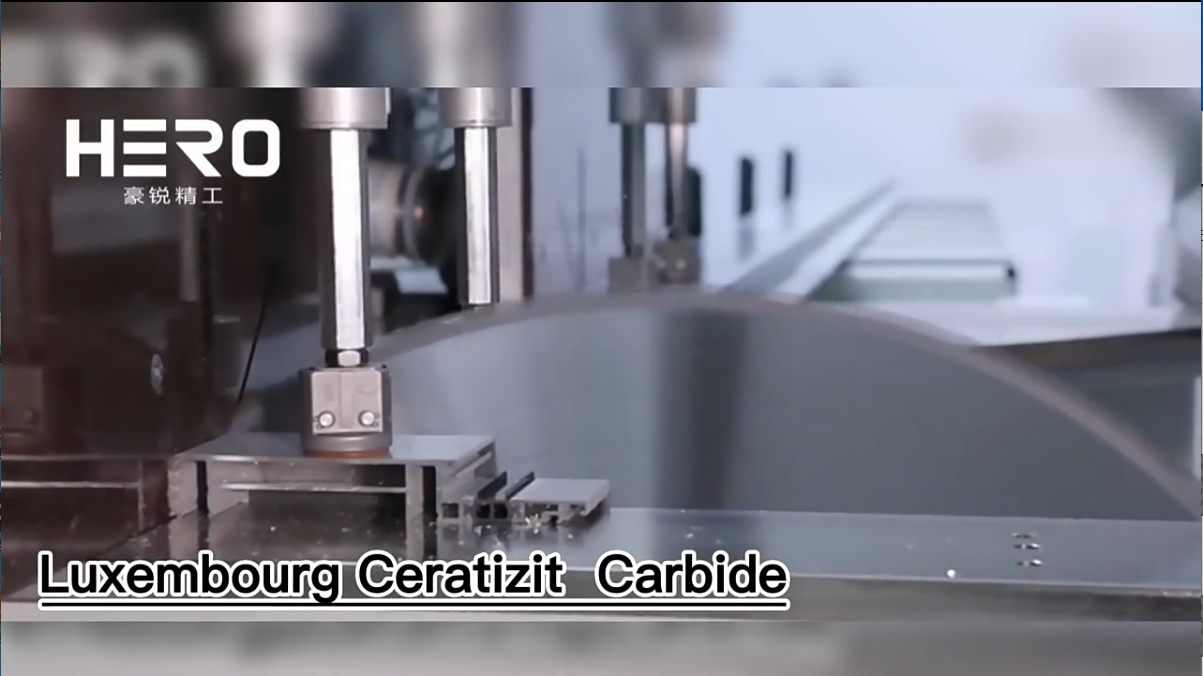

LUXEMBURG CERATIZIT ORIGINAL

I-CARBIDECERATlZIT i-carbide yoqobo, ikhwalithi ephezulu yomhlaba, Iqinile futhi ihlala isikhathi eside.

Sisebenzisa i-CERATIZIT NANO-grade carbide,HRA95°.Amandla okuqhekeka afinyelela ku-2400Pa, futhi sithuthukisa ukumelana kwe-carbide nokugqwala kanye ne-oxidation.I-carbide ukuqina nokuqina okungcono kwebhodi lezinhlayiyana, ukusika kwe-MDF,Isikhathi sokuphila singaphezu kuka-30% uma kuqhathaniswa nesaha elivamile lesigaba sezimboni.

Isicelo:

-

Zonke izinhlobo ze-aluminium, i-aluminium yephrofayili, i-aluminium eqinile, i-aluminium engenalutho. -

Umshini:Isaha eliyisigqoko esiphindwe kabili, isaha esishelelayo, isaha ephathekayo.

Isikhathi sokuthumela: Feb-27-2024

I-TCT Saw Blade

I-TCT Saw Blade IQHAWE Sizing Saw Blade

IQHAWE Sizing Saw Blade I-HERO Panel Sizing Saw

I-HERO Panel Sizing Saw IQHAWE Lokushaya I-Saw Blade

IQHAWE Lokushaya I-Saw Blade IQHAWE Eliqinile Izinkuni Saw Blade

IQHAWE Eliqinile Izinkuni Saw Blade IQHAWE Aluminium Saw

IQHAWE Aluminium Saw I-Grooving Saw

I-Grooving Saw Iphrofayili Yensimbi Yabona

Iphrofayili Yensimbi Yabona I-Edge Bander Saw

I-Edge Bander Saw I-Acrylic Saw

I-Acrylic Saw I-PCD Saw Blade

I-PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade I-PCD Panel Sizing Saw

I-PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade I-PCD Grooving Saw

I-PCD Grooving Saw PCD Aluminium Saw

PCD Aluminium Saw I-PCD Fiberboard Saw

I-PCD Fiberboard Saw I-Cold Saw Yensimbi

I-Cold Saw Yensimbi Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal I-Dry Cut Saw Blade ye-Ferrous Metal

I-Dry Cut Saw Blade ye-Ferrous Metal Cold Saw Machine

Cold Saw Machine I-Drill Bits

I-Drill Bits Izingcezu ze-Dowel Drill

Izingcezu ze-Dowel Drill Nge-Drill Bits

Nge-Drill Bits Ama-Hinge Drill Bits

Ama-Hinge Drill Bits TCT Isinyathelo Drill Bits

TCT Isinyathelo Drill Bits HSS Drill Bits/Mortise Bits

HSS Drill Bits/Mortise Bits Ama-router Bits

Ama-router Bits Amabhithi Aqondile

Amabhithi Aqondile Izingcezu Ezinde Eziqondile

Izingcezu Ezinde Eziqondile Amabhithi Aqondile we-TCT

Amabhithi Aqondile we-TCT I-M16 Amabhithi Aqondile

I-M16 Amabhithi Aqondile I-TCT X Amabhithi Aqondile

I-TCT X Amabhithi Aqondile 45 Degree Chamfer Bit

45 Degree Chamfer Bit I-Carving Bit

I-Carving Bit I-Corner Round Bit

I-Corner Round Bit I-PCD Router Bits

I-PCD Router Bits Edge Banding Amathuluzi

Edge Banding Amathuluzi I-TCT Fine Trimming Cutter

I-TCT Fine Trimming Cutter I-TCT Pre Milling Cutter

I-TCT Pre Milling Cutter I-Edge Bander Saw

I-Edge Bander Saw I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter I-PCD Pre Milling Cutter

I-PCD Pre Milling Cutter I-PCD Edge Bander Saw

I-PCD Edge Bander Saw Amanye Amathuluzi Nezesekeli

Amanye Amathuluzi Nezesekeli I-Drill Adapter

I-Drill Adapter Drill Chucks

Drill Chucks Isondo Lesanti Ledayimane

Isondo Lesanti Ledayimane Imimese Yokuhlela

Imimese Yokuhlela