Iyini inkinga nge-edge banding?

I-Edgebanding ibhekisela kukho kokubili inqubo kanye nomugqa wezinto ezisetshenziselwa ukudala ukusika okubukeka kahle emaphethelweni angaqediwe e-plywood, ibhodi lezinhlayiyana, noma i-MDF. I-Edgebanding ikhulisa ukuqina kwamaphrojekthi ahlukahlukene afana ne-cabinery ne-countertops, okuwanika ukuphela okuphezulu, ukubukeka kwekhwalithi.

I-Edgebanding idinga ukuguquguquka ngokuya ngesicelo sokunamathela. Ukushisa kwekamelo, kanye ne-substrate, kuthinta ukunamathela. Njengoba i-edgebanding yenziwe ngezinto eziningi ezihlukene, kubalulekile ukukhetha ingcina enikeza ukuguquguquka nekhono lokukwazi ukubopha kuma-substrates ahlukahlukene.

I-Hot melt glue iyingcina enezinjongo eziningi esetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza futhi ilungele wonke amabhande asenqenqemeni okuhlanganisa i-PVC, i-melamine, i-ABS, i-acrylic ne-wood veneer. I-Hot melt iyisinqumo esihle kakhulu ngoba iyathengeka, ingancibilika kabusha ngokuphindaphindiwe, futhi kulula ukusebenza ngayo.Okunye kokubi kwe-hot melt adhesive edge sealing ukuthi kune-glue seams.

Kodwa-ke, uma i-glue seams ibonakala, kungenzeka ukuthi imishini ayizange ilungiswe kahle. Kunezingxenye ezintathu eziyinhloko: ingxenye ye-pre-milling cutter, iyunithi ye-rubber roller kanye neyunithi ye-pressure roller.

1. Ukungajwayelekile engxenyeni yomsiki wangaphambi kokugaya

-

Uma isisekelo sebhodi eligaywe ngaphambili sinezigcawu futhi i-glue isetshenziswa ngokungalingani, iziphambeko ezifana nemigqa yeglue ngokweqile zizokwenzeka.Indlela yokuhlola ukuthi i-pre-milling cutter ijwayelekile yini ukuvala wonke amayunithi futhi uvule kuphela umsiki wangaphambi kokugaya. Ngemuva kokugaya i-MDF, bheka ukuthi ingaphezulu lebhodi liyisicaba yini. -

Uma ipuleti eligaywe ngaphambilini lingalingani, isisombululo wukushintsha esikhundleni salo isisiki esisha sangaphambi kokugaya.

2. Iyunithi yerola yerabha ayijwayelekile.

-

Kungase kube nephutha ku-perpendicularity phakathi kwerola enamathela enjoloba kanye nendawo ephansi yepuleti. Ungasebenzisa irula eliyisikwele ukukala i-perpendicularity. -

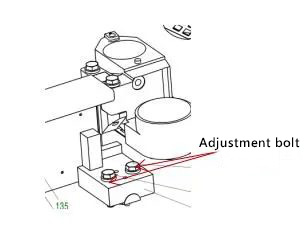

Uma iphutha likhulu kuno-0.05mm, kunconywa ukufaka esikhundleni sabo bonke abasiki be-milling.Lapho i-glue yokugqoka i-glue ingaphansi kokushisa kwemboni, izinga lokushisa liphezulu njenge-180 ° C futhi alikwazi ukuthintwa ngezandla ezingenalutho. Indlela elula yokuhlola ukuthola ucezu lwe-MDF, ulungise inani leglue libe lincane, futhi ubone ukuthi indawo yokugcina enamathiselwe iphezulu naphansi. Yenza izinguquko ezincane ngokulungisa ama-bolts ukuze ubuso bonke bokuphela busetshenziswe ngokulinganayo ngenani elincane leglue.

3. Iyunithi yamasondo okucindezela ayijwayelekile

-

Kukhona amamaki eglue asele ebusweni besondo lokucindezela, futhi indawo engalingani, okuzodala umphumela omubi wokucindezela. Idinga ukuhlanzwa ngesikhathi, bese uhlola ukuthi umfutho womoya nesondo lokucindezela kujwayelekile yini. -

Amaphutha ekumeni kwesondo lokucindezela azoholela nasekuvalekeni kahle konqenqemeni. Kodwa-ke, kufanele uqale uqinisekise ukuthi isisekelo sebhodi siyisicaba ngaphambi kokulungisa ukuma kwesondo lokucindezela.

Ezinye izici ezivame kakhulu ezithinta ikhwalithi ye-edge banding

1, Inkinga Yezisetshenziswa

Ngenxa yokuthi injini yomshini wokuhlanganisa onqenqemeni kanye nethrekhi ayikwazi ukubambisana kahle, ithrekhi ayizinzile ngesikhathi sokusebenza, khona-ke ama-banding strips ngeke alingane kahle nomphetho. ukuntuleka kweglue noma ukugqoka okungalingani kuvame ukubangelwa induku yokucindezela i-gluing engabambisani kahle ne-pad chain pad. Uma amathuluzi okunquma kanye namathuluzi e-chamfering kungalungiswanga kahle, akudingi nje kuphela ukusebenza okwengeziwe, futhi ikhwalithi yokusika kunzima ukuyiqinisekisa.

Ngamafuphi, ngenxa yezinga eliphansi lokugunyazwa kwemishini, ukulungiswa nokugcinwa, izinkinga zekhwalithi zizohlala. I-blunt yamathuluzi okusika nayo ithinta ngqo ikhwalithi yemikhawulo kanye nokunquma. I-engeli yokunquma enikezwe okokusebenza iphakathi kuka-0 ~ 30 °, futhi i-engeli yokunquma ekhethiwe ekukhiqizweni okuvamile ingu-20 °. I-blunt blade yethuluzi lokusika izobangela ikhwalithi yangaphezulu yehle.

2, Umsebenzi

Ukhuni olwenziwa ngumuntu njengempahla yokusebenza, ukuchezuka kogqinsi kanye nokucaba kungase kungafinyeleli ezindinganisweni. Lokhu kwenza ibanga ukusuka kumasondo e-pressure roller kuya phezulu kwesidlulisi kube nzima ukusetha. Uma ibanga lincane kakhulu, lizodala ingcindezi enkulu futhi lihlukanise imichilo ne-workpiece. Uma ibanga likhulu kakhulu, ipuleti ngeke licindezelwe, futhi imichilo ayikwazi ukuboshelwa ngokuqinile emaphethelweni.

3, Imichilo ye-Edge Banding

Imichilo yokubopha onqenqemeni iningi lenziwe nge-PVC, elingathinteka kakhulu imvelo. Ebusika, ubulukhuni bemichilo ye-PVC buzokhula obangela ukunamathela kweglue kuncipha. Futhi isikhathi eside sokulondoloza, indawo izoguga; amandla okunamathela ku-glue aphansi. Emapheshaneni enziwe ngephepha anogqinsi oluncane, ngenxa yokuqina kwawo okuphezulu nokujiya okuphansi (okufana no-0.3mm), kuzodala ukusikeka okungalingani, amandla okubopha anganele, kanye nokusebenza kabi kokunquma. Ngakho-ke izinkinga ezifana nokumosha okukhulu kwama-edge banding strips kanye nezinga eliphezulu lokusebenza kabusha zibucayi.

4, Igumbi Lokushisa kanye Nezinga Lokushisa Lomshini

Lapho izinga lokushisa langaphakathi liphansi, i-workpiece idlula emshinini wokubopha onqenqemeni, izinga lokushisa layo alikwazi ukunyuswa ngokushesha, futhi ngesikhathi esifanayo, i-adhesive ipholile ngokushesha okunzima ukuqedela ukubopha. Ngakho-ke, izinga lokushisa langaphakathi kufanele lilawulwe ngaphezu kwe-15 ° C. Uma kunesidingo, izingxenye zomshini wokubopha onqenqemeni zingashiswa ngaphambi kokusebenza (i-heater kagesi ingangezwa ekuqaleni kwenqubo yokubopha onqenqemeni). Ngesikhathi esifanayo, izinga lokushisa lokubonisa ukushisa kwenduku yokucindezela kwe-gluing kufanele lilingane noma libe phezulu kunezinga lokushisa lapho i-adhesive encibilikayo eshisayo ingancibilika ngokuphelele.

5,Ijubane lokudla

Isivinini sokuphakela semishini yesimanje yokuhlanganisa onqenqemeni ngokuvamile singu-18 ~ 32m/min. Eminye imishini enesivinini esiphezulu ingafinyelela ku-40m/min noma ngaphezulu, kuyilapho umshini wokuhlanganisa onqenqemeni lwe-curve unesivinini sokuphakela esingu-4 ~ 9m/min kuphela. Isivinini sokuphakela somshini wokuhlanganisa onqenqemeni othomathikhi singalungiswa ngokuya ngamandla okubopha onqenqemeni. Uma isivinini sokuphakela siphezulu kakhulu, nakuba ukusebenza kahle kokukhiqiza kuphezulu, amandla okubopha onqenqemeni aphansi.

Kuyisibopho sethu ukuqinisa ibhendi ngendlela efanele. Kodwa kufanele wazi, kusekhona ukukhetha okuzodingeka ukwenze lapho uhlola izinketho zokuhlanganisa onqenqemeni.

Kungani ukhetha i-HERO pre-milling cutter?

-

Ingakwazi ukucubungula izinto ezihlukahlukene. Izinto eziyinhloko zokucubungula ibhodi lokuminyana, ibhodi lezinhlayiyana, i-plywood ye-multilayer, i-fiberboard, njll. -

I-blade yenziwe ngezinto zedayimane ezingenisiwe, futhi kukhona ukubukeka okuphelele komklamo wezinyo impela. -

Iphakethe elizimele nelihle elinebhokisi nesipontshi ngaphakathi, elingavikela ngesikhathi sokuthutha. -

Ixazulula ngempumelelo iziphambeko zokugqokwa okungahlali isikhathi eside futhi okubucayi kwe-carbide cutter. Ingathuthukisa kakhulu izinga lokubukeka komkhiqizo. Nikeza impilo ende yokusebenzisa. -

Akukho ukumnyama, akukho ukuhlukana konqenqemeni, ukubukeka okuphelele komklamo wezinyo, ngokuhambisana ngokuphelele nobuchwepheshe bokucubungula. -

Sinesipiliyoni seminyaka engaphezu kwengu-20 futhi sinikezela ngezinsizakalo eziphelele zokuthengisa kwangaphambilini nangemuva kokuthengisa. -

Ikhwalithi enhle kakhulu yokusika ezintweni ezisekelwe ngokhuni eziqukethe imicu.

Isikhathi sokuthumela: Mar-01-2024

I-TCT Saw Blade

I-TCT Saw Blade IQHAWE Sizing Saw Blade

IQHAWE Sizing Saw Blade I-HERO Panel Sizing Saw

I-HERO Panel Sizing Saw IQHAWE Lokushaya I-Saw Blade

IQHAWE Lokushaya I-Saw Blade IQHAWE Eliqinile Izinkuni Saw Blade

IQHAWE Eliqinile Izinkuni Saw Blade IQHAWE Aluminium Saw

IQHAWE Aluminium Saw I-Grooving Saw

I-Grooving Saw Iphrofayili Yensimbi Yabona

Iphrofayili Yensimbi Yabona I-Edge Bander Saw

I-Edge Bander Saw I-Acrylic Saw

I-Acrylic Saw I-PCD Saw Blade

I-PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade I-PCD Panel Sizing Saw

I-PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade I-PCD Grooving Saw

I-PCD Grooving Saw I-PCD Aluminium Saw

I-PCD Aluminium Saw I-PCD Fiberboard Saw

I-PCD Fiberboard Saw I-Cold Saw Yensimbi

I-Cold Saw Yensimbi Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal I-Dry Cut Saw Blade ye-Ferrous Metal

I-Dry Cut Saw Blade ye-Ferrous Metal Cold Saw Machine

Cold Saw Machine I-Drill Bits

I-Drill Bits Izingcezu ze-Dowel Drill

Izingcezu ze-Dowel Drill Nge-Drill Bits

Nge-Drill Bits Ama-Hinge Drill Bits

Ama-Hinge Drill Bits TCT Isinyathelo Drill Bits

TCT Isinyathelo Drill Bits HSS Drill Bits/Mortise Bits

HSS Drill Bits/Mortise Bits Ama-router Bits

Ama-router Bits Amabhithi Aqondile

Amabhithi Aqondile Izingcezu Ezinde Eziqondile

Izingcezu Ezinde Eziqondile Amabhithi Aqondile we-TCT

Amabhithi Aqondile we-TCT I-M16 Amabhithi Aqondile

I-M16 Amabhithi Aqondile I-TCT X Amabhithi Aqondile

I-TCT X Amabhithi Aqondile 45 Degree Chamfer Bit

45 Degree Chamfer Bit I-Carving Bit

I-Carving Bit I-Corner Round Bit

I-Corner Round Bit I-PCD Router Bits

I-PCD Router Bits Edge Banding Amathuluzi

Edge Banding Amathuluzi I-TCT Fine Trimming Cutter

I-TCT Fine Trimming Cutter I-TCT Pre Milling Cutter

I-TCT Pre Milling Cutter I-Edge Bander Saw

I-Edge Bander Saw I-PCD Fine Trimming Cutter

I-PCD Fine Trimming Cutter I-PCD Pre Milling Cutter

I-PCD Pre Milling Cutter I-PCD Edge Bander Saw

I-PCD Edge Bander Saw Amanye Amathuluzi Nezesekeli

Amanye Amathuluzi Nezesekeli I-Drill Adapter

I-Drill Adapter Drill Chucks

Drill Chucks Isondo Lesanti Ledayimane

Isondo Lesanti Ledayimane Imimese Yokuhlela

Imimese Yokuhlela