In this article, we will review some of essential tooth type about circular saw blades that can help you cut through various types of wood with ease and precision. Whether you need a blade for ripping, crosscutting, or combination cuts, we have a blade for you. We will also provide you with some useful tips on how to choose the right blade for your project and how to maintain it for optimal performance.

Table of Contents

- Circular sawblades

- Typical tooth shapes and applications

- Influence of wood as a raw and basic material on cutting tools

- How to choose the right saw blade

Circular saw blades

Circular sawblades are progression instruments for cutting plastic and wood.

They consist of a saw plate made of polycrystalline diamond or tungsten carbide.

teeth brazed on the outside of it. They are employed to divide up workpieces.

To The goal is to make the cutting breadth as small as possible while minimizing the cutting loss and cutting pressures. Conversely, straight cuts are unaffected by Scores demand a specific level of blade stability, which inevitably calls for a concession.

< =”font-family: ‘times new roman’, times; font-size: medium;”>between the saw’s blade and cutting breadth.the geometry and material of the workpiece, the saw teeth in terms of geometry and shape. Positive cutting angles are typically utilized to minimize the cutting forces. For workpieces with thin walls, e.g.

Typical tooth shapes and applications

To keep the saw from catching on hollow profiles, negative cutting angles are required. The number of teeth is determined by the cut quality standards. The general rule is that the more teeth there are, the greater the cut quality, and the fewer teeth there are, the smoother the saw cut.

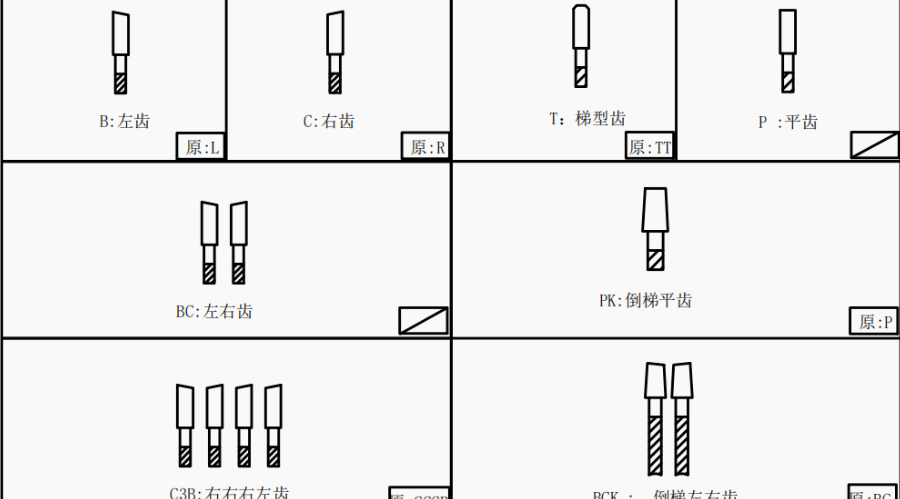

Classification of typical teeth forms and applications:

|

Tooth shape |

Application |

| Flat FZ | Solid wood, along and across grain. |

| Alternate, positive WZ | Solid wood along and across grain as well as glued, wood products.uncoated, plastic coated or veneered, plywood, multiplex, composite materials, laminated material |

| Alternate, negativeWZ | Solid wood across grain, hollow plastic profiles,non-ferrous metal extruded profiles and tubes. |

| Square/trapezoidal,positive FZ/TR | Wood products, uncoated, plastic coated or veneered, non-ferrous metal extruded profiles and tubes, non-ferrous metals, AI-PU sandwich panels, hollow plastic profiles, polymer plastics (Corian, Varicor etc.) |

| Square/trapezoidal, negative FZ/TR | Non-ferrous metal extruded profiles and pipes, hollow plasticprofiles, AI-PU sandwich panels. |

| Flat, bevelledES | Construction industry machine saws. |

| Inverted V/hollow groundHZ/DZ | Wood products, plastic-coated andveneered, coated profile strips (skirting boards). |

These are the seven essential tooth type about circular saw blades.

Influence of wood as a raw and basic material on cutting tools

However, in the actual application, because the cutting material is different, and at the same time the cutting direction is different. Cutting effect and tool life will also be affected.

While softwood and conifer, hardwood and broadleaf are generally comparable, there are some outliers, such as yew, which is a hardwood, and alder, birch, lime, poplar, and willow, which are softwoods.

Density, strength, elasticity, and hardness are essential variables in processing and tool selection. As a result, categorizing hardwood and softwood is significant since it gives a comprehensive reference to these qualities.

When carrying out wood processing and carpentry techniques, it is important to note that wood is a material of varying structure and quality. This is particularly illustrated by the growth rings of coniferous timber. The hardness varies considerably between earlywood and latewood. These factors must be taken into account during woodworking and the cutting material, cutting material geometry and processing parameters must be adjusted accordingly. When working with different types of wood, compromises are often necessary. Depending on the characteristics and parameters of the material you are processing, and even how many types of material, make the appropriate adjustments.

And for most cutting technology qualities, bulk density is the decisive factor. Bulk density is the ratio of mass to volume (including all particles). Depending on the type of wood, the bulk density usually ranges from 100 kg/m3 to 1200 kg/m3.

Other factors affecting cutting edge wear are wood composition, such as tannins or silicate inclusions.

Here are some common chemical components present in wood.

Natural tannins, such as those found in oak, cause chemical wear of the cutting edge of a tool.

This is especially true if the moisture content of the wood is high.

Silicate inclusions, such as those present in the tropical woods willow, teak or mahogany, are absorbed from the ground along with nutrients. It then crystallizes in vessels.

They increase abrasive wear on the cutting edge.

The difference in density between earlywood and latewood is usually significant

Often a sign of strong pre-cracking and a tendency to split during processing(e.g. European red pine). At the same time the color of the wood can be different.

The increasing global demand for wood is due to the fact that more and more trees are being cultivated into plantation forests. These so-called plantation forests are usually fast-growing

species such as radiata pine, eucalyptus and poplar. Compared to plants growing in natural forests, these plants have rougher annual rings and are denser and

strength are lower. Because of the greater susceptibility to trunk splitting and fiber separation, sometimes plantation timber harvesting can pose a real challenge.

It requires special processing techniques and special tooling solutions.

How to choose the right saw blade

Then after you understand the basics of the above, the difference in wood , the difference in tooth shape.

The next step is how to choose the right saw blade.In this article, we’ll show you how to do it in several ways

I.Selection basis for circular saw blades

According to the sawing material properties classification

1、Solid Wood: Cross-cutting, Longitudinal cutting.

Cross-cutting needs to cut off the wood fiber, the cut surface requires flat, can not have knife marks, and can not have a burr, that the saw blade used in the outer diameter of 10 inches or 12 inches and the number of teeth should be in the 60 teeth to 120 teeth, the thinner the material the use of the number of teeth correspondingly the more machines. Feed speed should be correspondingly slow. Longitudinal saw with relatively fewer teeth, feeding speed will be faster, so the requirements for chip removal is very high, so the requirements of the saw blade OD 10 inches or 12 inches in the number of teeth between 24 and 40 teeth.

2、Manufactured boards: Density board, particle board, plywood.

Cutting needs to fully consider the cutting force, and the problem of chip removal, the use of saw blades with an outside diameter of 10 inches or 12 inches of teeth should be between 60 teeth to 96 teeth.

After the above two rules,You can use BC teeth if there is a solid wood, plain board without veneer and the cut surface polish standards are not particularly high. When cutting particle board with veneer, plywood, density board, and so forth, use a saw blade with TP teeth. The fewer the teeth, the lower the cutting resistance; the more teeth, the larger the cutting resistance, but the smoother the cutting surface.

- Conclusion

There are many types of circular saw blades with different uses. In actual use, it should be combined with which material to cut, which use, combined with the machine. Select the appropriate tooth shape, the appropriate size of the corresponding type of saw blade.

We are always ready to provide you with the right cutting tools.

As a supplier of circular saw blades, we offer premium goods, product advice, professional service, as well as a good price and exceptional after-sales support!

In https://www.koocut.com/.

Break the limit and move forward bravely! It’s our slogan.

And will be determined to become a leading international cutting technology solution and service provider in China, in future we will contribute our great contribution to the promotion of domestic cutting tool manufacturing to advanced intelligence.

Post time: Aug-23-2023

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives