Can Metal Be Cut With a Mitre Saw?

What is a Mitre Saw?

A miter saw or mitre saw is a saw used to make accurate crosscuts and miters in a workpiece by positioning a mounted blade onto a board. A miter saw in its earliest form was composed of a back saw in a miter box, but in modern implementation consists of a powered circular saw that can be positioned at a variety of angles and lowered onto a board positioned against a backstop called the fence.

What is a Mitre Saw Used for?

A mitre saw is a type of stationary saw designed to make precision cuts at multiple angles. The blade is pulled downwards onto the material, unlike with a circular saw where it feeds through the material.

Mitre saws are best for cutting longer boards thanks to their large cutting capacities. Typical applications of a mitre saw include making quick and accurate miter cuts (such as at 45 degree angles for making picture frames) or for making cross cuts for moulding.You can make cross cuts, mitre cuts, bevel cuts and more all with this one versatile tool.

Mitre saws come in a variety of sizes. The size of the blade determines the cutting capacity of the saw. The larger the cutting capacity needed, the larger the saw you should opt for.

Types of Miter Saws

Miter saws can be split into three smaller categories based on specific functions related to each type of saw. The three types include a standard miter saw, a compound miter saw, and a sliding compound miter saw.

Single bevel: Can make miter cuts and bevel cuts in a single direction.

Double bevel: Can make bevel cuts in both directions. Double bevel mitre saws are better for when you need to make multiple angled cuts as they save time on switching the direction of material.

Compound miter saw: A compound mitre is the combination of a mitre and bevel cut. The mitre is made by rotating the base of the machine between 8 o’clock and 4 o’clock. Although the magic number for mitres seems to be 45°, many mitre saws are capable of cutting angles up to 60°. Bevel cuts are made by tilting the blade from 90° vertical through to a minimum of 45°, and often up to 48°– incorporating all the angles in-betwee.

Being able to make a compound mitre cut is ideal for applications such as cutting crown mouldings, or working on projects such as loft conversions, where angles of the walls and pitches of the ceiling must be considered. This is where the extraordinary angles of 31.6° and 33.9° featured on the gauges of some mitre saws come into play.

Sliding compound miter saw: A sliding compound mitre saw can perform the same mitre, bevel and compound cuts as a non-sliding compound mitre saw, with one additional feature. The sliding function increases cutting width capacity by allowing the motor unit and attached blade to travel along telescopic rods.

As many slide compound mitre saws rely on being portable, the sliding mechanism is an ingenious way of offering very wide cuts, whilst keeping the machine relatively compact.

Can You Cut Through Metal With a Mitre Saw?

The Mitre saw is a woodworker’s best friend given how versatile and handy they are, but can you cut through metal with a mitre saw?

In general, the density and toughness of metallic materials are not too difficult for a mitre saw’s motor to handle. However, there are some factors that you need to be aware of before rushing in. First of all, the mitre saw’s blade set is not ideally suited to this task, so the first step is to find a suitable replacement. Please note that there are some safety precautions to be aware of as well.

What Blade Should You Use for Cutting Through Metal?

Certainly, your typical mitre saw blade will do a spectacular job of cutting through wood and chopping trims, however, working with metal using the same type of blade spells disaster. Of course, that shouldn’t come as a surprise as such blades were designed specifically with cutting wood in mind. Even though some mitre saws may be suitable for non-ferrous metals (such as soft change google or copper) – it isn’t recommended as a permanent solution. If you are working on a project that may require quick and precise cuts into metal but don’t have a better tool to hand, then swapping out your wood-cutting carbide blades for an alternative is an easy solution. The good news is that there are plenty of high-quality metal-cutting blades available of HERO, so finding something suitable won’t be too difficult. Just make sure that you pick the appropriate variety depending on the type of cuts you will be making

What Happens if You Don’t Switch the Blade Out and Cut Straight Into Metal?

If you decide you can’t be bothered with the hassle and wish to try your luck with cutting into metal using your mitre saw and its existing blade, here’s what could happen:

-

Mitre saws work with more speed than crafting metal requires – this leads to more friction between the cutting surface and the blade itself -

This will subsequently lead to both the tool and work-piece heating up significantly which can have a detrimental effect on the metallic structure -

Blazing hot tools and materials will put you and your workstation at a much higher risk of damage and/or injury

Should You Use a Mitre Saw for Cutting Into Metal?

Just because you can use a mitre saw for cutting mental it doesn’t mean that it should be your permanent solution. The fact is, swapping your mitre saw blades for cutting metal isn’t the most cost-effective approach as they will constantly need replacing. Again, the mitre saw’s RPM is far higher than is required for cutting through metal. This will only result in more sparks flying around than is necessary. Additionally, with over-use and regular overheating, the mitre saw’s motor may begin to struggle. You can use your mitre saw now and again for cutting through metal if you work on projects that do not regularly require cutting into metal. However, if cutting into metal is something that you are likely going to need to do more often then get yourself a specialist metal cutting tool, for example:

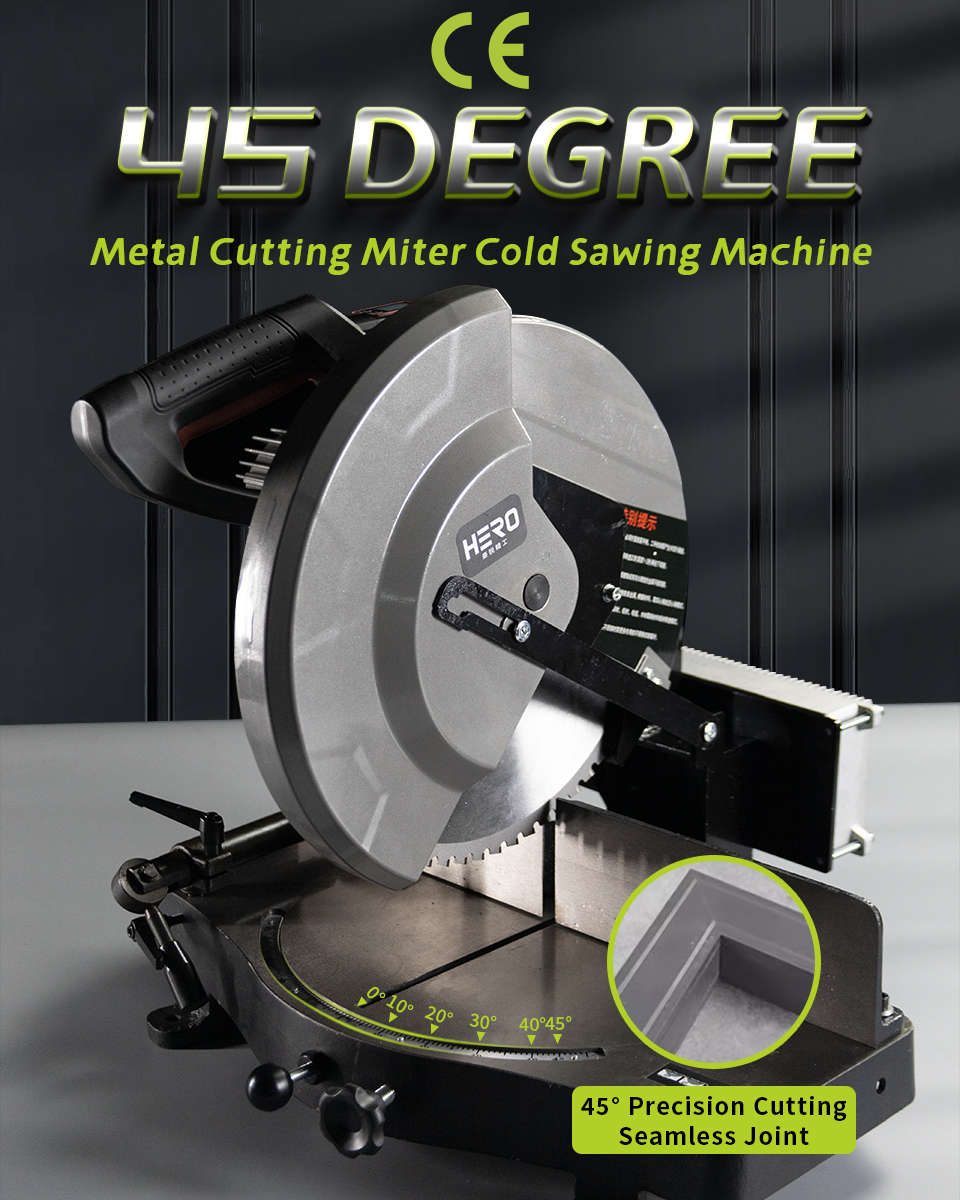

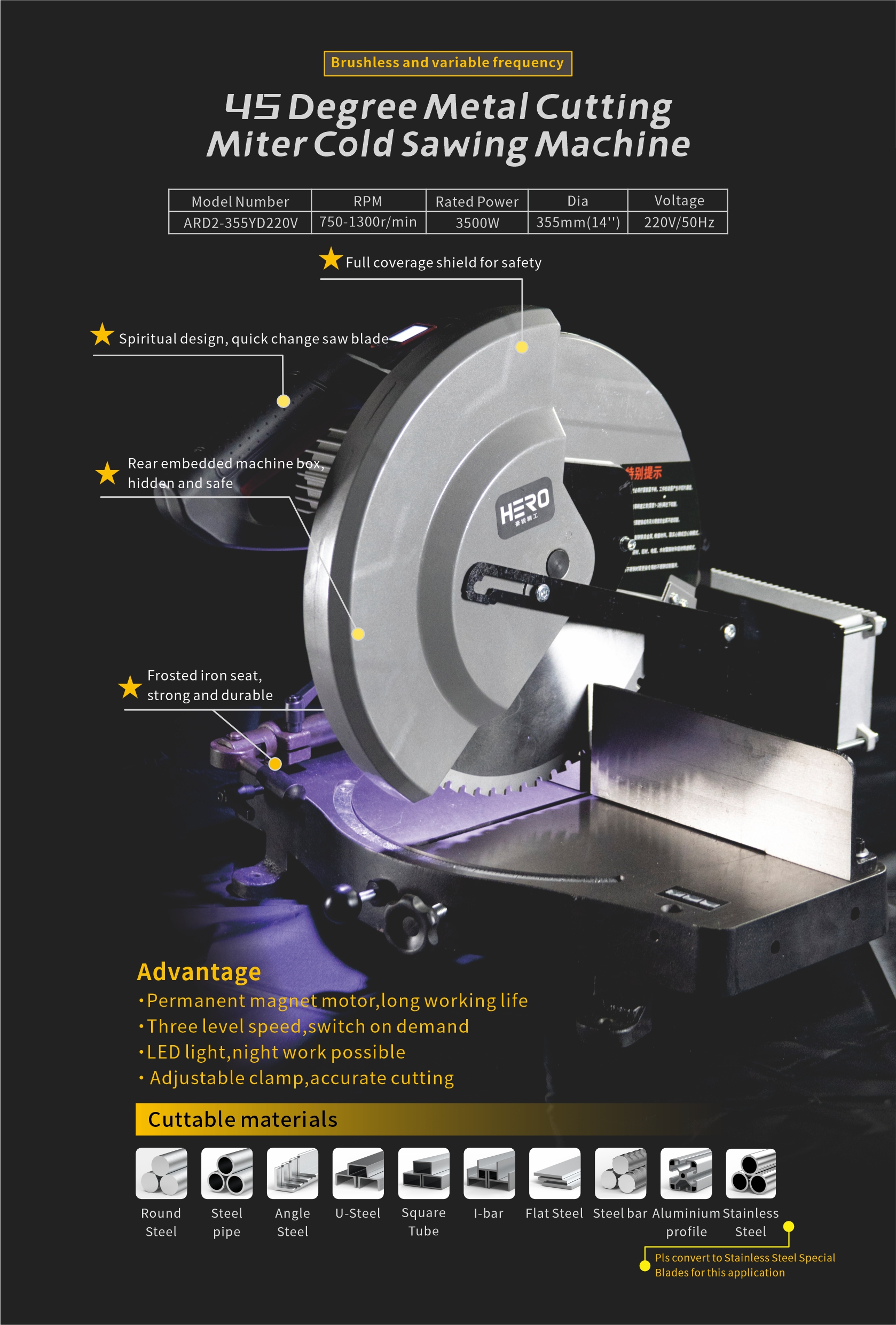

HERO Cold Metal Miter Saw Machine

-

Metal-Material Cutting Technology: One Saw, One Blade, Cuts All metals. Smooth cutting through Round Steel, Steel pipe, Angle Steel, U-Steel & more -

Accurate Angles: 0˚ – 45˚ bevel tilt and 45˚ – 45˚ miter angle capability -

Saw Balde Included: Premium Metal Cutting saw blade included (355mm*66T)

Advantage:

-

Permanent magnet motor,long working life. -

Three level speed,switch on demand -

LED light,night work possible -

Adjustable clamp,accurate cutting

Multi-Material Cutting:

Round Steel,Steel Pipe,Angle Steel,U-steel,Square Tube,I-bar,Flat Steel,Steel Bar,Aluminium Profile,Stainless Steel (Pls Convert to Stainless Steel Special Blades for this Application)

Post time: Jun-20-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives