How do you manually cut acrylic?

Acrylic materials are increasingly popular in a variety of industries, from signage to home decor. In order to effectively process acrylic, it is crucial to use the right tools, and one of the most critical tools in this process is an acrylic saw blade. In this article, we’ll delve into the ins and outs of acrylic saw blades, their uses, and best ways to cut acrylic panels, you can choose the right one according to your actual situation, of course, the cutting process is sure to protect yourself not to get hurt.

Understand acrylic and its properties

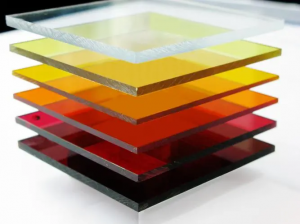

Before we get into the details of acrylic saw blades, it’s necessary to understand the material itself. Acrylic(or plexiglass as it’s sometimes called), also known as polymethylmethacrylate (PMMA), is a versatile thermoplastic known for its clarity, strength, and UV resistance,Acrylic sheets come in a variety of sizes and an unbelievable number of colors. Clear acrylic is both clearer than glass and about 10 times more resistant to impacts than glass.The fact that it can be strong and beautiful at the same time make it a great material for professionals and DIYers both to utilize it in all sorts of projects from decorative pieces and displays, to protective covers and panels. Acrylic panels can be used to enclose a 3D printer or make an edge lit sign.However, cutting can be difficult without the right tools, as incorrect cuts can cause chipping, cracking, or melting.

Why use acrylic saw blades?

Acrylic saw blades are specifically designed for precision cutting of acrylic materials. Sharp teeth are essential for achieving good results. Unlike standard wood or metal saw blades, acrylic saw blades have unique features that make them suitable for this type of material. Carbide tipped saw blades are recommended for superior cuts and longer life of the cutting edge. They typically have a higher tooth count and are made of materials that reduce friction and heat buildup that can damage acrylics. It is also important to dedicate saw blades for cutting acrylic only. Cutting other materials on saw blades intended for acrylic will dull or damage the blade and lead to poor cutting performance when the blade is used again to cut acrylic.

Types of saw blades used for cutting acrylic sheet

When choosing an acrylic saw blade, it is important to understand the different types available. Remember these two key points when cutting acrylic manually:

-

Avoid creating too much heat while you cut. Tools that generate heat tend to melt the acrylic rather than cutting it cleanly. Melted acrylic looks more like lumpy slime than the clean polished sheet it was. -

Avoid unnecessary bending while you cut. Acrylic doesn’t like to be bent, it can crack. Using aggressive tools or not supporting the material as you cut can bend it and that can cause unwanted breakage.

Circular saw blade

Circular saw blades are one of the most commonly used types for cutting acrylic. They come in various diameters and tooth shapes. Blades with a high tooth count (60-80 teeth) are great for clean cuts, while blades with a lower tooth count can be used for faster cuts but may result in a rough surface.

Jigsaw Blade

Jigsaw blades are great for making intricate cuts and curves in acrylic sheets. They come in various tooth configurations, and using a fine-tooth blade will help minimize chipping.

Band saw blade

Band saw blades are great for cutting thicker acrylic sheets. They provide a smooth surface and are less likely to cause melting due to their continuous cutting action.

Router bit

Although a milling cutter is not a saw blade in the traditional sense, it can be used to shape and finish edges on acrylic. They are especially useful for creating decorative edges or grooves.

Choose the right acrylic saw blade

-

Number of teeth

As mentioned before, the number of teeth significantly affects the quality of the cut. The higher the tooth count, the smoother the cut, while the lower the tooth count, the faster and rougher the cut.

-

Material

Acrylic saw blades are usually made of carbide material, which is durable and heat-resistant. Make sure the blade you choose is specifically designed for cutting acrylic to avoid damage.

-

Blade thickness

Thinner blades tend to produce less waste and provide cleaner cuts. However, they may bend or break more easily, so consider the thickness of the acrylic you are using.

Prepare to cut acrylic

-

Safety first

When working with acrylics and saw blades, be sure to wear appropriate safety gear, including goggles and gloves. Acrylic can crumble and the resulting dust may be harmful if inhaled.

-

Ensure material safety

Make sure the acrylic sheet is securely clamped to a stable work surface. This will prevent movement during cutting, which can lead to inaccuracies and chipping.

-

Tag your clips

Use a fine-tipped marker or scoring tool to clearly mark the cut lines. This will serve as a guide and help you maintain accuracy.

Tips on How to Cut Acrylic Sheet Without Breaking or Cracking

-

Slow and steady wins the race

When cutting acrylic, maintaining a steady speed is crucial. Rushing can cause overheating, which can cause the acrylic to melt or warp. Let the blade do the work without forcing it through the material.

-

Using the backplane

Support the material well as you work it. Don’t let it bend more than you have to.Placing a backing sheet underneath the acrylic sheet will help prevent the underside from chipping. This is especially important for thicker boards.

-

Keep blades cool

Don’t cut too fast (or too slow with a dull blade). If you notice that your acrylic is starting to melt, it may be because the temperature is too high. Consider using a lubricant or cutting fluid designed for acrylics to keep the blade cool and reduce friction,A small bottle of water or alcohol also can provide coolant and lubrication.

-

Keep the surface covered until you’re finished.

This can mean leaving the factory film in place or applying some masking tape while you work with it. When you do finally pull the masking off you get the satisfaction of seeing that pristine surface for the first time.

Finishing Your Acrylic Cut Parts

One thing all these cutting methods have in common is they can leave the cut edges looking duller or rougher than the perfectly shiny faces. Depending on the project, that may be ok or even desirable, but you’re not necessarily stuck with it. If you decide you want to smooth out the edges, sandpaper is a great way to do it. Similar tips apply to sanding edges as cutting. Avoid too much heat and avoid bending.

-

Use a quality sandpaper polish the edges

Use fine sandpaper to smooth down any rough edges left from the cutting process. Starting with around 120 grit sandpaper and work your way up. Make sure to sand in one direction to avoid additional scratches.You may be able to start with a higher grit sandpaper if your cut came out relatively smooth already. You shouldn’t need a rougher grit than 120, acrylic sands pretty easily. If you go with a power sander instead of hand sanding, keep it moving. Don’t stay in one spot too long or you can generate enough heat to melt the acrylic.

-

Move onto polishing and buffing

if you’re after a polished glossy edge that matches the face you’ll want to polish. Polishing is similar to sanding, you’ll start with coarser grits and work your way finer. You may be satisfied with the finish from one grit of polishing, or you may want to put in some extra effort to get that deep glossy look. Automotive polishing compound works great on acrylic, just follow the same tips above. Wipe and polish the edges with a soft cloth until shiny.

-

Cleaning

Finally, clean the acrylic surface with a mild soap solution and a soft cloth to remove dust or debris from the cutting process.

Conclusion

Gloves and glasses are a good idea to protect yourself as you cut any material, acrylic is no exception. As we mentioned above, if you only remember two things after reading this article, it should be to avoid excess heat and bending to get the best DIY cuts.

By following this article, you can improve your skills and confidence when using an acrylic saw blade. Whether you’re a DIY enthusiast or a professional, mastering the art of acrylic cutting will open up a world of creative possibilities. Happy cutting!

Need a Supplier of Cutting Acrylic Service

If you really need some cutting acrylic sheets circular saw blade, you are welcome to contact us at any time, and we are happy to help you achieve your requirements. Maybe here, you want to know more about cutting acrylic.

HERO is a leading China saw blade manufacturer, if you want to know more about saw blade products, we are happy to hear from you.

Post time: Oct-24-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives