How to Choose a Blade for Your Circular Saw?

A circular saw will be your greatest ally for a range of DIY projects. But these tools aren’t worth a thing unless you have high-quality blades.

When selecting a circular saw blade, it is important to consider the following:

the materials you plan to cut (e.g. wood, composite materials, non-ferrous metals, plastic, etc.); this will determine the type of blade you need;

the tooth design: depends on the material you are cutting and the type of cut required;

the gullet: i.e. the size of the spaces between the teeth; the larger the gap, the faster the cut;

the bore: i.e. the diameter of the hole at the centre of the blade; this is measured in mm and can be made smaller with reducing bushes;

the blade thickness in mm;

the depth of the cut: depends on the diameter of the blade (which varies depending on saw type);

the blade and teeth tip material; depends on the materials being cut;

the number of teeth: the more teeth, the cleaner the cut; represented by the letter Z on the blade;

the number of revolutions per minute (RPM): linked to the diameter of the blade.

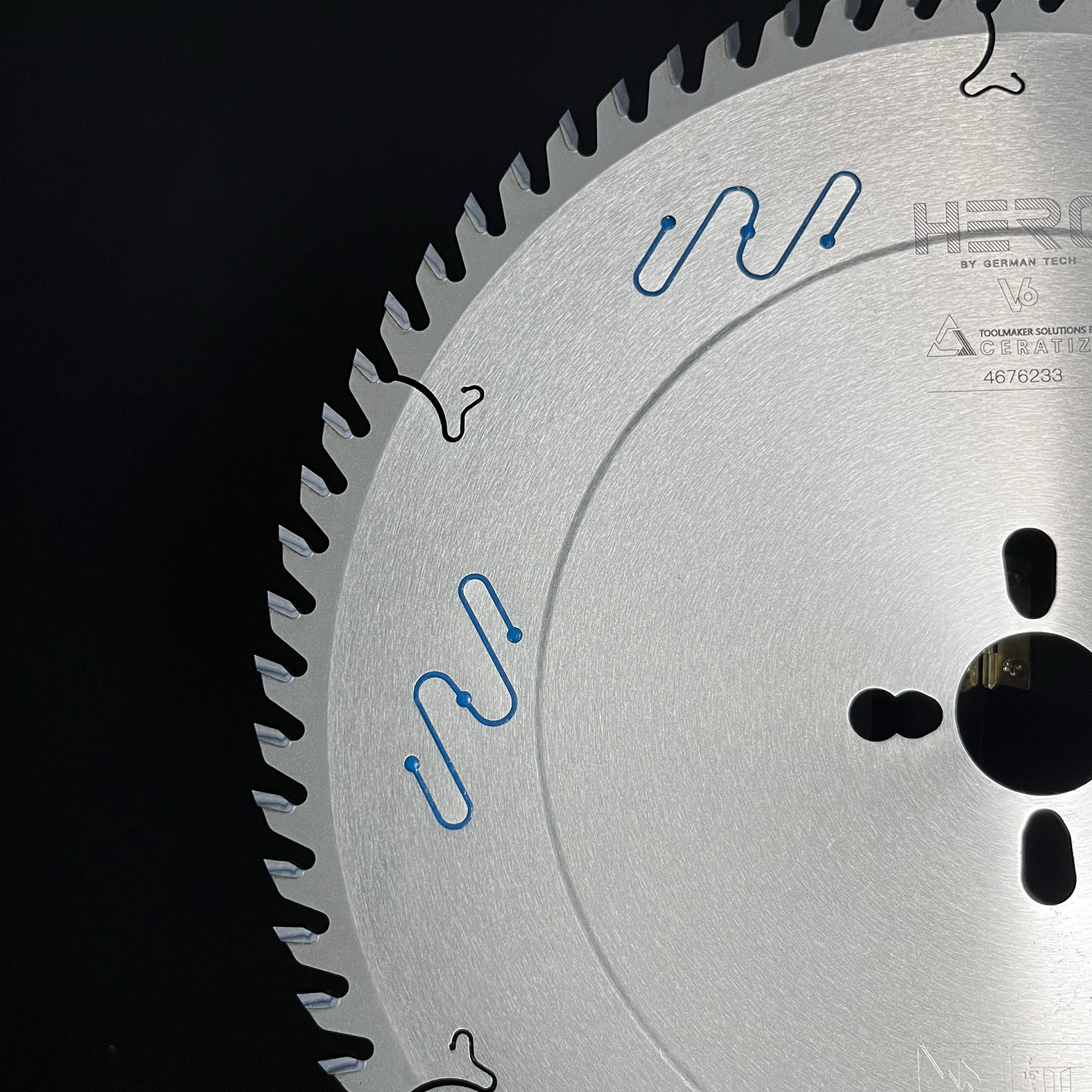

Note that expansion slots are incorporated into the saw blade so that the metal can expand as it heats up. Some logos and abbreviations may be specific to the brand or manufacturer.

Bore and blade diameter

Circular saw blades are toothed metal discs featuring a hole in the centre called a bore. This hole is used to secure the blade to the saw. Essentially, the bore size must match the size of your saw but you can select a blade with a larger bore provided that you use a reducer ring or bush to attach it to the saw. For obvious safety reasons, the diameter of the bore must also be at least 5 mm smaller than the nut that secures the blade to the bore shaft.

The diameter of the blade must not exceed the maximum size accepted by your circular saw; this information will be set out in the product specifications. Buying a blade that is slightly smaller is not dangerous but it will reduce cutting depth. If you’re not sure, refer to the manufacturer’s instructions or check the size of the blade currently on your saw.

The number of teeth on a circular saw blade

A saw blade consists of a series of teeth that perform the cutting action. Teeth are set out all around the circumference of a circular saw blade. The number of teeth varies depending on numerous factors, including application, so you’ll have to determine whether you’ll be using the blade for ripping or crosscutting.This is the part of the blade that is responsible for making cuts. The space between each tooth is called the gullet. Larger gullets allow sawdust to be expelled more quickly. A blade with larger teeth spaced further apart is therefore ideal for rip cuts (i.e. cutting with the grain).

Inversely, smaller teeth allow for a finer finish, particularly when making crosscuts (i.e. working against the grain). Of course smaller teeth will mean slower cuts.

It is important to note that the gullet size can actually be more important than the number of teeth featured. A 130 mm blade with 24 teeth will have the same gullets as a 260 mm blade with 48 teeth. If it’s all sounding a bit complicated, don’t worry – blades are usually marked to indicate the type of job they are equipped to handle whether this be coarse work, finishing work or a range of tasks.

Rotation Speed

Rotation speed of a circular saw should follow the manufacturer’s recommendations for the specific saw blade. All saw blades are designed for safe use at a maximum number of Revolutions per Minute or RPM”, representing the number of turns in a minute. The manufacturers provide this information on the blade’s packaging, as it is an important piece of safety information. When buying circular saw blades, it is important to ensure that the maximum RPM of the saw which the blade will be attached to is less than the maximum RPM stated on the blade’s package.

RPM by Saws

Non-geared electric motors typically run at 1,725 RPM or 3,450 RPM. Many power tools are direct drive, meaning the blade mounts directly to the motor shaft. In the case of these direct drive tools, such as handheld circular saws (not worm driven), table saws and radial arm saws, this will be the RPM which the blade is operating at. However, there are some circular saws which are not direct drive and operate at different speeds. Worm drive handheld circular saws typically run between 4,000 and 5,000 RPM. Belt driven table saws can also run over 4,000 RPM.

Speed by Material

Although saws and blades are rated by their RPM, cutting of material isn’t. Cutting type, ripping or crosscutting, is a different story, too. That’s because the RPM of a saw isn’t a good indicator of its cutting speed. If you take two saws, one which has a 7-1/4” blade and the other which has a 10” blade, and run them at the same speed, as measured in RPM, they won’t cut at the same speed. That’s because even though the center of both blades is moving at the same speed, the outer edge of the larger blade is moving faster than the outer edge of the smaller blade.

5 steps for choosing a circular saw blade

-

1.Check the features of your saw. Once you know the diameter and bore size of your saw, you just have to select a blade to suit your needs.

-

2.While log saws and mitre saws require special blades, the blade you choose for your circular saw will depend on what you will be using it for. Bear in mind that you will have to weigh up cutting speed and quality of finish.

-

3.The blade application is often indicated by the manufacturer making it easier to narrow down your choices regarding gullet size and tooth type.

-

4.Universal, multi-purpose blades offer a good balance between cutting speed and quality of finish if you don’t use your circular saw that often.

-

5.The various logos and abbreviations can be confusing. In order to make the right choice, follow the manufacturer’s recommendations. If you only want to study one feature, think about the design and material of the teeth.

Questions About Choosing a Saw Blade?

Do you still have questions about which saw blade is right for your cutting tasks? The experts at HERO Saw can help. Feel free to contact us for more information today. If you’re ready to shop for a saw blade, check out our inventory of saw blades!

Post time: Jun-06-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives