How to cut Acrylic Sheets with circular saw blade?

Acrylic sheets have become increasingly popular in modern interior design due to their versatility and durability. Their functional and aesthetic benefits make them a common alternative to glass, as they are lightweight, shatter-resistant, and more impact-resistant than glass. They can be used on furniture, countertops, and other surfaces, enhancing their functionality and aesthetic appeal.

What are Acrylic Sheets?

Acrylic sheets, also known as plexiglass or acrylic glass, are transparent or coloured thermoplastic sheets made from synthetic polymers. A thermoplastic is a material that is moldable at high temperatures and solidifies when cooled. Their impressive optical clarity is another reason why they have become an excellent alternative to traditional glass in various applications.

How are Acrylic Sheets Made?

Acrylic sheets are generally manufactured using the following two processes:

1.Extrusion: In this process, the raw acrylic resin is melted and pushed through a die, resulting in continuous sheets of uniform thickness.

2.Cell Casting: This involves pouring liquid acrylic into molds, yielding higher-quality sheets suitable for specialized applications.

Where are Acrylic Sheets Used?

acrylic sheets can be used on boards, panels and as laminates on various surfaces. They can be heat-molded into various shapes and sizes, offering flexibility in design and enabling creative applications.

Acrylic sheet uses can be in various settings, such as offices, restaurants, shops, and homes. They can bring style and durability to any space and are commonly used in the below application areas:

-

Bedroom and living room furniture -

Bathroom and Kitchen cabinets -

Tabletops and countertops -

Floors and interior walls

Properties of Acrylic Sheets:

Optical Clarity: They have excellent transparency, making them an ideal substitute for traditional glass.

Impact Resistance: They are significantly stronger than glass, making them highly resistant to impact and less likely to shatter or break.

Lightweight: They are lightweight, making them easier to handle and install compared to glass or other materials.

Chemical Resistance: They are resistant to many chemicals, making them suitable for use in laboratories and chemical environments.

Scratch and Stain Resistance: They have a hard surface that resists scratches, maintaining their appearance over time.

Hygienic: They are easy to clean and maintain, making them a hygienic choice for applications in kitchen furniture and bathroom cabinets.

Recyclable: They are recyclable, contributing to sustainability and environmental conservation.

Benefits of Using Acrylic Sheets

-

Durability -

Easy Maintenance -

Variety of Finishes -

Versatility

Durability: They are tough and resist scratches & scraping, making them a long-lasting solution. With UV-resistance, they do not crack or yellow when exposed to sunlight, maintaining their clarity and colour.

Easy Maintenance: They resist stains and do not absorb moisture. Their high water-resistance makes them ideal for applications in moist environments such as bathrooms and kitchens. The non-porous surface prevents water damage and facilitates easy cleaning.

Variety of Finishes: They come in a wide variety of patterns, colours, and textures that make them a popular choice.

Versatility: They can be used on a variety of surfaces, including countertops, cabinets, walls, and furniture.

Types of circular saw blades used for cutting acrylic sheet

There are several saw blades on the market that can effectively cut acrylic sheet. Sharp teeth are essential for achieving good results. Carbide tipped saw blades are recommended for superior cuts and longer life of the cutting edge. It is also important to dedicate saw blades for cutting acrylic only. Cutting other materials on saw blades intended for acrylic will dull or damage the blade and lead to poor cutting performance when the blade is used again to cut acrylic.

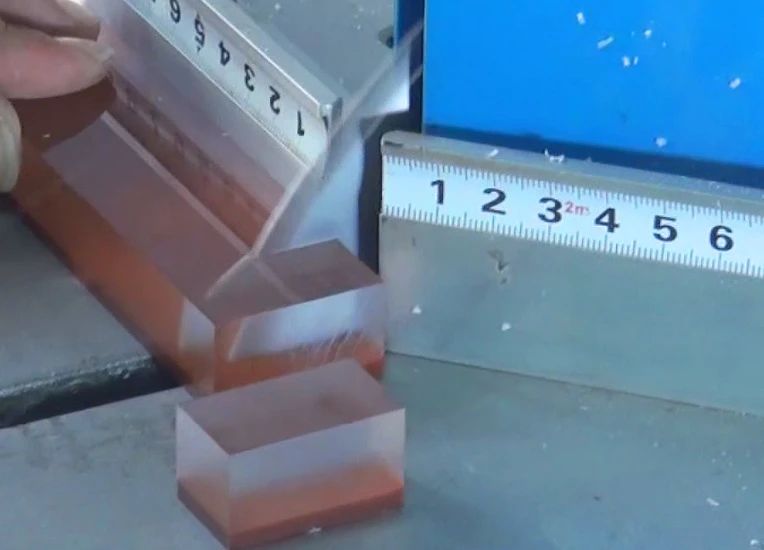

With a table saw you’re back to being limited to straight line cuts, but thanks to the fence, the cuts can be very straight. A table saw is a great way to break larger sheets down into smaller sheets.

-

Prepare your acrylic sheet by masking the surface near the cut. Acrylic scratches easier than glass, so pushing a saw across it can leave marks. Most acrylic comes with a protective paper on both sides, you can leave that on while you cut. If you’re cutting a piece that’s already had that paper removed, masking tape works great also. -

Mark your cut line on the masking or acrylic itself. Permanent marker or dry erase markers work well on acrylic. -

Use a sharp fine pitch blade, usually a metal cutting blade can work well, but there are special blades made for cutting acrylics. Avoid aggressive blades with fewer teeth per inch, like those for rough wood cutting. Those types of blades will apply more bending pressure as they cut and can cause chipping instead of clean cuts. -

Support the material well as you cut. Cutting with too much material unsupported may cause the material to bounce up and down with the blade and that can cause cracking.

One tip that can help with table saw cutting is to sandwich your acrylic between two pieces of sacrificial material. Plywood or mdf work great. It doesn’t need to be very thick, it just needs to support the material on both sides as the blade both enters and exits the acrylic. This can help prevent the saw blade from chipping the material, as even a small gap between blade and support can be enough to notice a rougher cut. A zero clearance insert on your saw works great also.

You can buy table saw blades specifically for acrylic and plastics. Those are good choices since fine tooth metal cutting blades aren’t very common for table saws. A very fine wood finishing blade can work also. Just avoid blades for rough cutting or ripping.

Tips on How to Cut Acrylic Sheet Without Break or Cracking

-

Keep the cut cool. Don’t cut too fast (or too slow with a dull blade). A small bottle of water or alcohol can provide coolant and lubrication. -

Support the material well as you work it. Don’t let it bend more than you have to. -

Choose the right blade. Avoid aggressive fast cutting blades. -

Keep the surface covered until you’re finished. This can mean leaving the factory film in place or applying some masking tape while you work with it. When you do finally pull the masking off you get the satisfaction of seeing that pristine surface for the first time.

Finishing Your Acrylic Cut Parts

One thing all these cutting methods have in common is they can leave the cut edges looking duller or rougher than the perfectly shiny faces. Depending on the project, that may be ok or even desirable, but you’re not necessarily stuck with it. If you decide you want to smooth out the edges, sandpaper is a great way to do it. Similar tips apply to sanding edges as cutting. Avoid too much heat and avoid bending.

Use a quality sandpaper

Starting with around 120 grit sandpaper and work your way up. You may be able to start with a higher grit sandpaper if your cut came out relatively smooth already. You shouldn’t need a rougher grit than 120, acrylic sands pretty easily. If you go with a power sander instead of hand sanding, keep it moving. Don’t stay in one spot too long or you can generate enough heat to melt the acrylic. Power tools are faster, but that can mean you get into trouble before you realize it.

Sand until all saw marks are gone

You want to sand enough with the first grit that all the saw marks are gone and you’re left with a consistently flat scratched surface. Once the entire edge is evenly scratched, move up to the next finest grit. Stick with each grit until the scratches from the previous grit are gone and the edge shows consistent finer scratches, then it’s time to move up in grit again.

Safety Recommendations

Gloves and glasses are a good idea to protect yourself as you cut any material, acrylic is no exception.

Post time: May-24-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives