Should You Use Thin Kerf Blade?

Table saws are the beating heart of many woodshops. But if you’re not using the right blade, you’re not going to get the best results.

Have you been dealing with lots of burnt wood and tearout? Your blade choice might be the culprit.

Some of it’s pretty self explanatory.A ripping blade is meant for ripping (cutting a board lengthwise with the grain). A crosscut blade is for crosscuts (cutting a board across its width across the grain).

A NOTE ON QUALITY TABLE SAW BLADES

Before we talk about the types of blades to buy, we need to talk about quality.

It’s worth your time and money to invest in high quality table saw blades.

Like many consumables, cheap blades are only cheap up front. In the long run, they end up costing you more.Good blades resist heat better, stay sharp longer, and can be resharpened multiple times.Plus, they just work better. Which means you’ll have a better time in the shop.

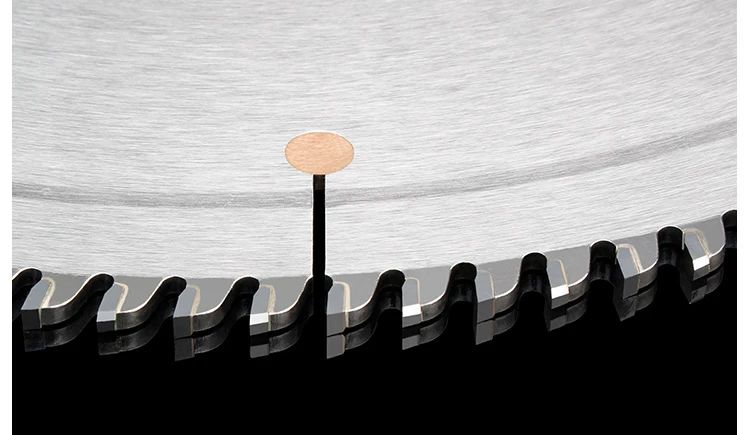

SAW BLADE KERF

Saw blade “kerf” refers to the thickness of the slot which the saw blade will cut. It is often used as well to define the thickness of the blade itself, or at least the widest point on the blade, as this will define the width of cut made. The thickness affects the cutting width, cost, power consumption, and the amount of wood lost during the processing. Kerf is generally wider than the blade plate.Every woodworker knows that no two saw blades are alike, and you need to be sure you select the right one for your project. One of the features to look for in a particular saw blade is the blade’s kerf — or the width of the material that is removed when cutting. This is determined by the width of the blade’s carbide teeth. Certain kerfs are suitable for different projects.

Kerf and Thickness

If you look at the construction of a carbide tipped circular saw blade, you will note that the blades teeth are welded onto the blade plate, and are thicker than it. In the case of high speed steel saw blades, the teeth are integral with the blade, although the kerf is still thicker than the thickness of the blade plate. This is caused by the teeth being “offset” from the blade. All that means is that they are bent slightly to the side, alternating sides from one tooth to the next. One more thing that can affect the saw kerf is the flatness of the blade. If you can imagine how a blade would look that is slightly warped. In that case, the teeth would not follow each other in the exact same line, but rather wobble back and forth a bit, much as a car tire that is mounted on a bent rim. This wobble would actually cause the blade to cut a wider kerf than the thickness of the teeth warrants.

Steel

Since sheet metal is often rolled at the mill where it is forged, then unrolled and cut into sheets, before fabrication, it may not be totally flat. While your eye probably cannot see the amount of curve in the blade, it can still cause the saw kerf to be greater than the thickness of the blade and teeth warrant. Extremely high grade circular saw blades are made from steel that wasn’t rolled at the steel mill. This steel is much more costly than regular sheet steel, due to the increased labor involved in handling it in processing. However, a blade made with this type of steel will have no wobble, making for the smoothest possible cut.

WHAT IS A THIN KERF SAW BLADE?

Kerf is defined as the width of material that is removed by the cutting/sawing process. A thick or full kerf circular saw blade will create a wider slot in the wood you are sawing, therefore, removing more material and creating more dust. It is less affected by heat during cutting and will not bend, so there’s no blade deflection. Conversely, a thin kerf circular saw blade creates a narrower slot and removes less material.It will also put less strain on your motor since there is less material being removed. These saws are ideal for motors under three horsepower.

Why Thin Kerf Blades?

The width (thickness) of the cut affects power consumption. The more material that is removed, the greater the level of resistance and friction leading to an increase in power drain. A thin kerf blade will remove less material, creating less resistance and friction increasing effciency and reducing power drain, which is especially important when using a cordless saw.

The thickness of the cut also changes the amount of wood lost during the cutting process. This is considered important,especially when cutting expensive wood where the user is keen to preserve as much of the material as possible.

The kerf of the blade also affects the amount of dust created. A thick or full kerf blade will create more dust. This is a key factor to consider if you are not in a well-ventilated workspace or you don’t have the right dust extraction. Whilst wood dust is not as harmful as silica dust, it does pose a certain risk to health; inhaling the dust into the lungs for prolonged periods can cause breathing problems and lead to lung diseases.

Does the quality matter?

Yes. When considering what blade to buy, especially a thin kerf blade, it is essential to make sure the quality of the blade is high.

A thin kerf blade means that the body of the blade will also be thinner. lf the blade is not made of high-quality steel and not hardened and tempered correctly, it can waiver and cause a poor-quality cut.

WHEN TO USE A THIN KERF BLADE

Usually, it is best to stick to the blade size and thickness that is recommended for the saw.Good quality saws will tell you this.

However, if you are using a cordless circular saw then you will want to use a thin kerf blade in order to preserve the battery life of the saw.

Also, a lot of professional joiners who are cutting through expensive wood may prefer to stick to a thin kerf saw blade however I would make sure that the saw l was using was suitable for a thin kerf blade.

Should l always use a thin kerf blade on my cordless machine?

You are best to stick to a thin kerf for your cordless machine in most situations. Most manufacturers will in fact, recommend a thin kerf blade for best compatibility and machine run-time & efficiency. lf you can reduce the friction when sawing, you will reduce the drain on the battery and make the battery last longer.

Not Sure What to Buy?

If you are unsure if full kerf or thin kerf blades are right for you, feel free to reach out to HERO Saw. We’ll help you determine if our blades will work with your saw.

Post time: Jun-28-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives