introduction

In the modern metalworking industry, cold saw machines have become an indispensable technology, offering unprecedented efficiency, precision, and sustainability. From dry cut cold saws to portable metal circular saw machines, these innovative tools have not only transformed our perception of metal cutting but also opened up limitless possibilities for various application fields. Let’s delve into the importance of cold saw machines, their widespread applications in the metalworking industry, and the opportunities for continuous development.

Metalworking has always been at the core of manufacturing, spanning across sectors such as construction, automotive manufacturing, aerospace, machinery production, and many others.

Traditional metal cutting methods, such as grinding or oxy-fuel cutting, while effective, often come with high heat generation, substantial waste, and extended processing times. These challenges have sparked the demand for more advanced solutions

The emergence of cold saw machines has filled this need. They employ dry-cutting technology to cut metal materials efficiently, precisely, and with minimal heat. This not only reduces energy waste but also lessens the environmental impact, making the cutting process more sustainable.

In the following we will introduce you to several common cold saw machines.

Table of Contents

-

Common cold saw machines

-

1.1 what is the dry cut cold saws?

-

1.2 Advantages of Portable metal circular saw machine

-

1.3 Handheld rebar cold cutting saw

-

How to choose the right cold saw machine for you

-

Conclusion

Common cold saw machines

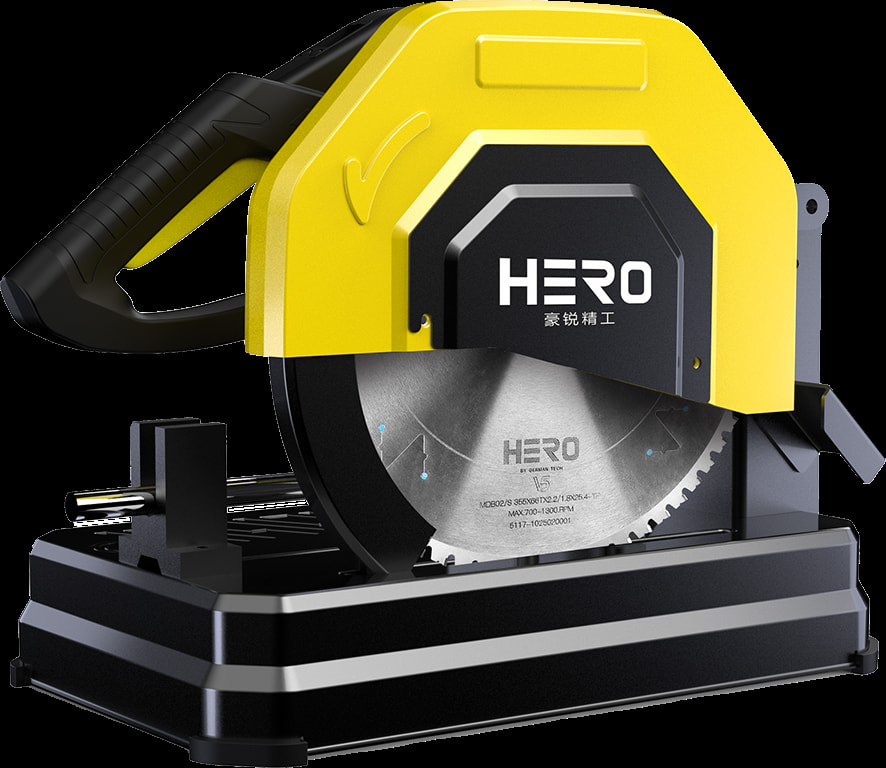

1.1 what is the dry cut cold saws?

Processing of various long strips of medium and low carbon steel, rectangular tubes, angle iron, steel bars…

Cutting material: Dry metal cold saw is suitable for processing low alloy steel, medium and low carbon steel, cast iron, structural steel and other steel parts with a hardness below HRC40, especially modulated steel parts.

Key features of dry cut cold saws include their high-speed circular blades, often equipped with cbide or cermet teethwhich are specifically engineered for metal cutting. Unlike traditional abrasive saws, dry cut cold saws operate without the need for coolant or lubrication. This dry cutting process minimizes heat generation, ensuring that the structural integrity and properties of the metal remain intact.

Dry cut cold saws are known for their accuracy, producing Clean and burr-free cuts, which reduce the need for additional finishing or deburring work. The absence of coolant results in a cleaner work environment and eliminates the mess associated with traditional wet cutting methods.

These machines come in various sizes and configurations, making them suitable for a wide range of metal cutting applications, from light-duty tasks to heavy industrial projects. They offer adjustable cutting angles and depths, providing versatility for different project requirements.

Equipment classification

-

Fixed frequency metal cold cutting saw (brushed DC motor) -

Variable frequency metal cold cutting saw (brushless DC motor)

1.2 Advantages of Portable metal circular saw machine

Processing materials: processing various color steel composite panels, medium and low carbon steel, purification panels, wood, and stone.

A portable metal circular saw machine, also known as a portable metal cutting circular saw, is a power tool designed for cutting various types of metal materials. It is a handheld or hand-guided tool that features a circular saw blade with specially designed teeth for cutting through metals, such as steel, aluminum, or stainless steel.

Key features and components of a portable metal circular saw machine typically include:

Circular Saw Blade:These machines use circular saw blades that are specifically designed for cutting metal. These blades have carbide teeth or other hardened materials to withstand the hardness of metal.

Portable Design: The machine is designed to be easily carried and operated by hand, making it suitable for on-site work and tasks that require mobility.

Safety Features::Safety features like blade guards and safety switches are incorporated to protect the operator during use.

a. Common saw blade models

180MM (7 inches)

230MM (9 inches)

Handheld Rebar Cold Cutting Saw

Processing materials:

Small steel bars, steel pipes, rebar, channel steel, solid materials, round steel, square steel

【Wide Applications】This rebar cutting saw can be used to cut various metal materials with diameter range 1-40mm, including steel bars, fully threaded rods, coil rods, pipes, anti-theft rods and oil pipes, etc. It’s also designed to produce minimal sparks and can cut a variety of metal materials for you quickly, safely and efficiently.

A handheld cold saw for rebar is a powerful and portable cutting tool designed specifically for cutting reinforced steel bars, commonly known as rebar. These handheld tools are engineered to provide efficient and precise cuts in various sizes of rebar, making them an essential choice for professionals in construction, concrete work, and steel reinforcement projects.

Key features of a handheld cold saw for rebar typically include a high-torque motor, a circular saw blade with carbide or high-speed steel teeth optimized for cutting metal, and adjustable settings for cutting depth and angle. The cold cutting process generates minimal heat, preventing any structural damage or weakening of the rebar. This makes it an ideal choice for applications where the integrity of the steel reinforcement is crucial, such as in building foundations, bridges, or concrete structures.

These handheld tools are valued for their portability, allowing workers to make on-site cuts swiftly and accurately, reducing the need for transporting pre-cut rebar and ensuring that materials fit precisely within the construction framework. Whether it’s for reinforcing concrete, building infrastructure, or other construction projects, a handheld cold saw for rebar is a reliable and efficient tool that enhances productivity while maintaining the integrity of the steel components.

.

parameter

140mmX36T (inner diameter 34mm, outer diameter 145mm), 145mm*36T (inner diameter 22.23mm),

The diameters of standard parts are:

110MM (4 inches), 150MM (6 inches), 180MM (7 inches), 200MM (8 inches), 230MM (9 inches), 255MM (10 inches), 300MM (12 inches), 350MM (14 inches), 400MM ( 16 inches), 450MM (18 inches), 500MM (20 inches), etc.

The bottom groove saw blades of precision panel saws are mostly designed to be 120MM.

How to choose the right cold saw machine for you

In the following we will give a table showing the relationship between cold saw machines and materials

| Diameter | Bore | Kerf/Body | Tooth | Application |

| 250 | 32/40 | 2.0/1.7 | 54T/60T/72T/80T | Medium and low carbon steels, Common steel pipes |

| 250 | 32/40 | 2.0/1.7 | 100T | Common steel pipes, Thin-wall steel pipes |

| 285 | 32/40 | 2.0/1.7 | 60T/72/80T | Medium and low carbon steels, Common steel pipes |

| 285 | 32/40 | 2.0/1.7 | 100T/120T | Common steel pipes, Thin-wall steel pipes |

| 285 | 32/40 | 2.0/1.7 | 140T | Thin-wall steel pipes |

| 315 | 32/40/50 | 2.25/1.95 | 48T/60T/72T/80T | Medium and low carbon steels, Common steel pipes |

| 315 | 32/40/50 | 2.25/1.95 | 100T/140T | Common steel pipes |

| 360 | 32/40/50 | 2.6/2.25 | 60T/72T/80T | Medium and low carbon steels, Common steel pipes |

| 360 | 32/40/50 | 2.5/2.25 | 120T/130T/160T | Thin-wall steel pipes |

| 425 | 50 | 2.7/2.3 | 40T/60T/80T | Medium and low carbon steels, Common steel pipes |

| 460 | 50 | 2.7/2.3 | 40T/60T/80T | Medium and low carbon steels, Common steel pipes |

| 485 | 50 | 2.7/2.3 | 60T/80T | Medium and low carbon steels, Common steel pipes |

| 520 | 50 | 2.7/2.3 | 60T/80T | Medium and low carbon steels, Common steel pipes |

| 560 | 60/80 | 3.0/2.5 | 40T/60T/80T | Medium and low carbon steels, Common steel pipes |

Conclusion

Cold saw machine is an efficient, precise and energy-saving metal cutting equipment, which plays an important role in the metal processing industry. With the advancement of technology and market demand, cold saw machines are constantly innovating and improving, providing more processing possibilities and advantages for various metal materials.

Cold sawing machines can not only improve the quality and speed of metal cutting, but also reduce the cost and environmental impact of metal cutting, thereby increasing the competitiveness and efficiency of the metal processing industry.

If you are interested in cold sawing machines, or want to learn more about the applications and benefits of cold sawing machines, we recommend that you delve deeper and explore the various features and functions of cold sawing machines. You can get more information and advice by searching online or consulting a professional cold saw machine supplier. We believe that cold saw machines will bring more opportunities and value to your metal processing career.

If you are interested,we can provide you best tools.

We are always ready to provide you with the right cutting tools.

As a supplier of circular saw blades, we offer premium goods, product advice, professional service, as well as a good price and exceptional after-sales support!

In https://www.koocut.com/.

Break the limit and move forward bravely! It’s our slogan.

Post time: Oct-25-2023

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives