About the metal cutting,we have many tools to cut it.But Do you really know the difference between them?

Here’s some knowledge you can’t afford to miss!

Table of Contents

-

Cold Saw Basics

-

Comparison with traditional grinding wheels and cutting data

-

FAQ about Cold Saw Use and Installation

-

Conclusion

Cold Saw Basics

Cold sawing, or metal cold sawing, is the abbreviation for the sawing process of metal circular saw machines. In the process of metal sawing, the heat generated when the saw blade is sawing the workpiece is transferred to the sawdust through the saw teeth, and the sawed workpiece and saw blade are kept cool, so it is called cold saw.

1. Cold Saw Cutting Features

High precision of workpiece, good surface roughness, effectively reduce the processing intensity of the next process;

Fast processing speed, effectively improve production efficiency;

High degree of automation, one person can operate multiple equipment, effectively reducing labour costs;

The workpiece will not produce deformation and internal organisation changes;

The sawing process is low in sparks, dust and noise.

2: Purpose of Sawing

The purpose of sawing is to achieve high-quality sawing effect

Then based on the above principles, we can draw a formula.

Good sawing effect = professional matching sawing equipment + high-quality saw blade + correct sawing application parameters

Depend on this formula,so we can control the sawing effect from the 3 aspect.

3: Metal cold saw – Common processing materials

Processable cutting materials:

Channel steel ,I-beam ,round steel rebar,steel pipe,aluminum alloy

Unprocessable cutting materials:

Stainless steel (requires special saw blade) Iron wire Quenched and tempered steel

These are some common materials that can be cut and those that cannot be cut

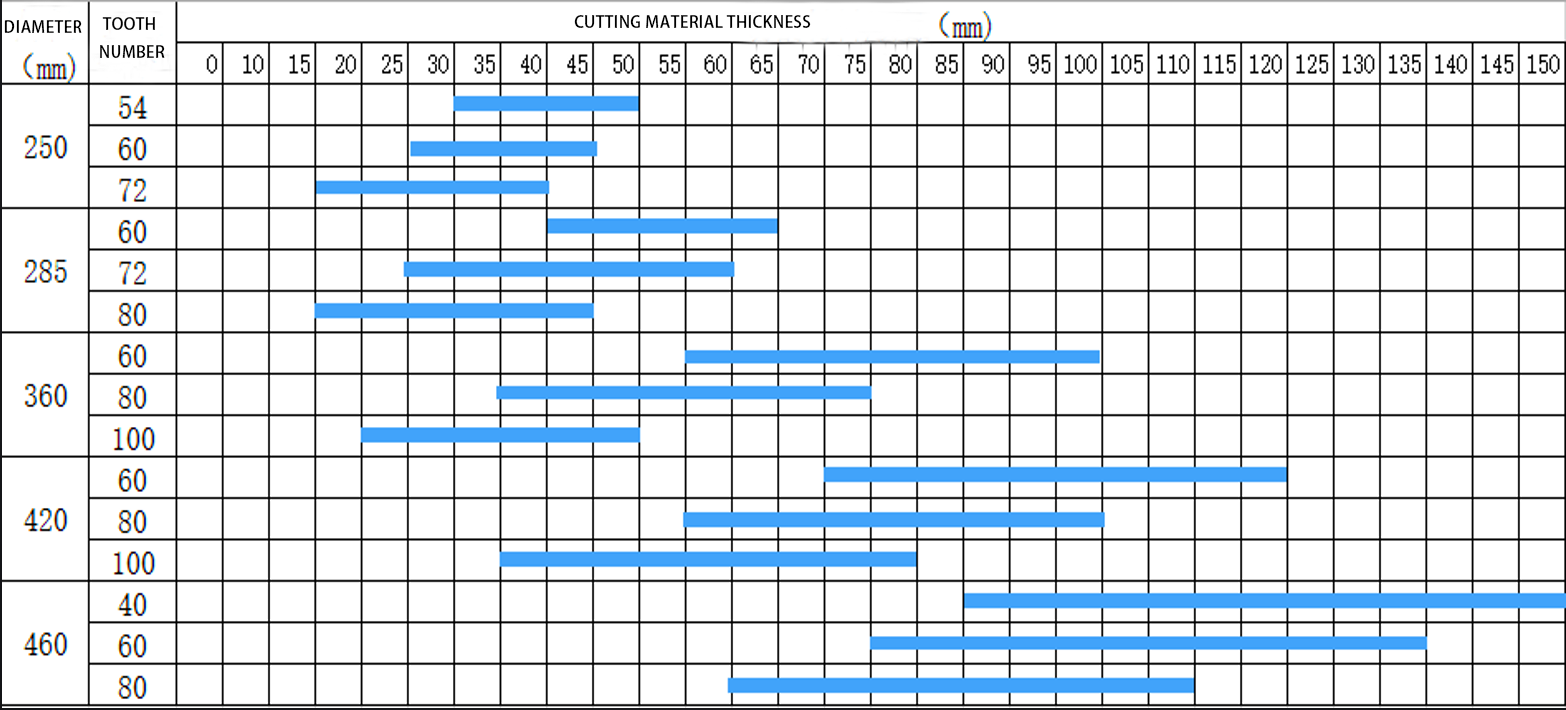

At the same time, the size selection of metal cold saw blades also needs to be based on the thickness of the cutting material.

As in the table below.

Comparison with traditional grinding wheels and cutting data

Grinding Wheel Disc

The cutting disc belongs to the grinding wheel. It is made of abrasive and binder resin for cutting ordinary steel, stainless steel and non-metallic materials. It is divided into resin cutting disc and diamond cutting disc.

Using glass fiber and resin as reinforced bonding materials, it has high tensile, impact and bending strength, and is widely used in the production and blanking of ordinary steel, stainless steel and non-metal

But the grinding wheel discs are used by people. There are some shortcomings that cannot be ignored.

Metal cutting cold saws solve these pain points very well.

In what follows, we will discuss the following issues.

1 Safety

Grinding wheel disc: potential safety hazard. Operators can inhale a lot of particulate matter from the grinding wheel disc during the actual cutting process, causing health problems and posing fire hazards. Cutting materials tend to have large sparks.

Simultaneously, grinding wheel sheet breaks easily, causes the hidden danger of staff’s safety.

The grinding wheel blades in production must have stable quality and no defects, because any saw blade breakage may be caused by small defects. Once broken, it will cause harm to people.

During the cutting process, it is necessary to always pay attention to whether there are irregular shapes or cracks. If there is any situation, it is necessary to stop using and replace the grinding wheel immediately.

Cold saw: no dust and less sparks during cutting. The safety hazard is small. Operators can use it with confidence. At the same time, the quality and hardness of cold saws are greatly improved compared to grinding wheels.

The cutting life is far longer than that of grinding discs.

2 Cutting Quality

The cutting efficiency of the Grinding wheel cutting disc is low, and it generally requires multiple cuts to complete the task. In addition, the cutting accuracy of the grinding wheel is relatively low, and it is difficult to meet the needs of high-precision cutting.

The processing efficiency is low, the overall cost is high, and the labor intensity of the operator is high because of the high-speed rotation of the processed grinding wheel and the cutter bowl, which generates a lot of dust and noise.

The cross section of the cutting material is discolored and has poor flatness.

Generally speaking, the fewer teeth the blade has, the faster it will cut, but also the rougher the cut. If you want a cleaner, more precise cut, you should choose a blade with more teeth.

Cold Saw Blade:

Cold cutting: The temperature generated during metal cold sawing is relatively low, which reduces thermal deformation in the cutting area and hardening of the material.

Smooth Cuts: Compared to traditional thermal cutting methods, metal cold saws produce flatter cuts, reducing the need for subsequent processing.

Accuracy: Due to the application of cold cutting technology, metal cold saws can provide precise cutting dimensions and flat cutting surfaces.

Efficient cutting: Metal cold saws can cut quickly with high-speed rotating saw blades to improve production efficiency. This makes cold saws excellent in situations such as high-volume production and urgent deliveries that need to be done quickly.

Cold sawing also has lower energy consumption and environmental pollution. Because cold saws use lubricants to reduce heat generation, they consume less energy than hot saws. At the same time, the cutting process of the cold saw will not produce obvious smoke and harmful gases, which reduces the pollution to the environment.

Cutting material, the section is flat, vertical without burrs.

Use high-quality materials, impact resistance, no tooth chipping

3:Cutting data

Flat Steel 1cm*8cm, 6 seconds Bearing Steel 6cm, 11 seconds

Square Steel 2cm*4cm, 3 seconds Rebar 3.2cml,3 seconds

Round Steel 5cm, 10 seconds

Cold saw blade only takes about 10 seconds to process 50mm round steel.

Grinding wheel cutting disc takes more than 50 seconds to process 50 round steel, and the resistance is getting bigger and bigger.

FAQ about Cold Saw Use and Installation

FAQ

1:The saw blade is reversed. There is no direction requirement for the grinding wheel, and the dry cutting cold saw cannot be used in reverse.

2: The equipment starts sawing before reaching the operating speed.

3: Cutting without clamping the workpiece or other illegal operations of fixing the workpiece arbitrarily.

4: Use it at an uneven speed when sawing, resulting in unsatisfactory cross-section results.

5: When the cutting sharpness is insufficient, remove the saw in time, repair it, and extend the cutting life.

Saw Blade Installation Requirements

-

The saw blade must be handled with care and must not collide with foreign objects to avoid damage to the blade edge or deformation of the saw blade body. -

Before installing the saw blade, you must confirm that the inner and outer flanges of the equipment are free of wear and bumps to ensure their flatness. -

Confirm and adjust the wear status of the wire brush. If the wear is excessive, replace it in time (the wire brush plays a vital role in chip removal). -

Clean the oil stains and iron filings on the corners of the equipment spindle, wire brush, clamping block, flange and protective cover to ensure that no foreign matter remains. -

After installing the saw blade and before tightening the screws, tighten the saw blade in the opposite direction to eliminate the gap between the positioning hole and the positioning pin and avoid toothing of the saw blade. -

After confirming that the nut is locked, close the machine cover, turn on the fuel injection switch (the amount of oil should be sufficient), idle for about 2 minutes, stop the machine and check whether there are scratches or heat on the surface of the saw blade. Normal production can be carried out only if there are no abnormalities. -

Select reasonable cutting parameters based on the characteristics of the material to be cut. In principle, for materials that are difficult to cut, the sawing speed and feed speed should not be excessive. -

When sawing, judge whether the sawing is normal by observing the sawing sound, the cut surface of the material, and the curling shape of the iron filings. -

When cutting with a new saw blade, in order to ensure the stability of the saw blade, the cutting parameters can be slowed down to about 80% of the normal speed during initial cutting (called the tool running-in stage), and the sawing returns to normal sawing after a certain period of time. cut speed.

Conclusion

Metal processing is a relatively difficult processing method in the field of sawing. Due to the characteristics of processed products, high requirements and high standards are determined for the design, manufacture and use of saw blades.

Compared with the previous saw blades, the cold saw has solved some problems well, and its own high cutting efficiency.

Cold saw is a trending product in metal processing and cutting in the future.

We are always ready to provide you with the right cutting tools.

As a supplier of circular saw blades, we offer premium goods, product advice, professional service, as well as a good price and exceptional after-sales support!

In https://www.koocut.com/.

Break the limit and move forward bravely! It’s our slogan.

Post time: Sep-01-2023

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives