What are the problems with aluminum cutting?

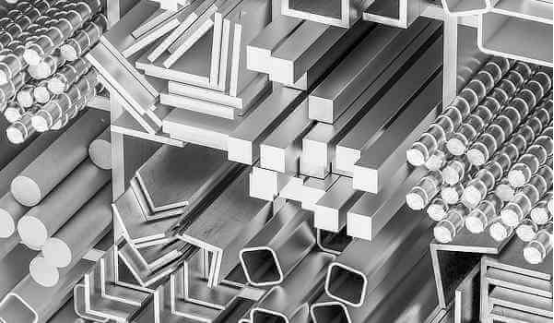

Alu alloy refers to a “compound material” consisting of aluminum metal and other elements to improve performance characteristics. Other elements many include copper, magnesium silicon or zinc, just to mention a few.

Alloys of aluminum have exception properties including better corrosion resistance, improved strength and durability, just to mention a few.

Aluminum is available in a number of different alloys and each series may have several different tempers in which to choose. As a result, some alloys may be much easier to mill, shape or cut than others. It is vital to have a complete understanding of the “workability” of each alloy, because they have such different properties.

These find use in a wide range of industries, including automotive, marine, construction, and electronics.

However, cutting and grinding aluminum effectively and efficiently can be challenging for several reasons. Aluminum is a softer metal with a lower melting point than other materials, such as steel. These characteristics can lead to loading, gouging or heat discoloration when cutting and grinding the material.

Aluminum is soft by nature and can be difficult to work with. In fact, it may form a gummy buildup when cut or machined. This is because aluminum has a relatively low melting temperature. This temperature is low enough that it will often fuse to the cutting edge due to the heat of friction.

There is no substitute for experience when it comes to working with aluminum. For example, 2024 is not too difficult to work with, but is nearly impossible to weld. Each alloy has properties which give it advantages in some applications but can be disadvantages in others.

CHOOSING THE RIGHT PRODUCT fOR ALUMINUM

Perhaps the most important factor to consider with aluminum machining is the machinist. Understanding the properties of aluminum is essential but so is choosing the right tools and knowing how to set the parameters for the machining process. Even with CNC machining methods, one must take many things into account or you could end up with a great deal of scrap, and this can take away any profits you make from the job.

There are many tools and products available for cutting, grinding and finishing aluminum, each with advantages and disadvantages. Making the right choice for the application can help companies gain better quality, safety, and productivity, while also minimizing downtime and labor costs.

When machining aluminum, you need very high cutting speeds to get the best results. In addition, cutting edges must be hard and very sharp. This kind of specialized equipment can represent a substantial investment to the machine shop on a limited budget. These costs make it wise to rely on an aluminum machining specialist for your projects.

Analysis and solutions to problems with abnormal noise

-

If there is an abnormal sound when the saw blade is cutting aluminum, it is likely that the saw blade is slightly deformed due to external factors or excessive external force, thus triggering a warning.

-

Solution: Recalibrate the carbide saw blade.

-

The main shaft clearance of the aluminum cutting machine is too large, causing jump or deflection.

-

Solution: Stop the equipment and check to see if the installation is correct.

-

There are abnormalities in the base of the saw blade, such as cracks, blockage and distortion of the silencer lines/holes, special-shaped attachments, and other items other than the cutting material encountered during cutting.

-

Solution: Determine the problem first and handle it accordingly based on different causes.

Abnormal noise of the saw blade caused by abnormal feeding

-

The common cause of this problem is the slipping phenomenon of the carbide saw blade.

-

Solution: Readjust the saw blade

-

The main shaft of the aluminum cutting machine is stuck

-

Solution: Adjust the spindle according to the actual situation

-

The iron filings after sawing are blocked in the middle of the sawing path or in front of the material.

-

Solution: Clean up the iron filings after sawing in time

The sawed workpiece has texture or excessive burrs.

-

This situation is usually caused by improper handling of the carbide saw blade itself or the saw blade needs to be replaced, for example: the matrix effect is unqualified, etc.

-

Solution: Replace the saw blade or recalibrate the saw blade

-

Unsatisfactory side grinding of the sawtooth parts results in insufficient accuracy.

-

Solution: Replace the saw blade or take it back to the manufacturer for regrinding.

-

The carbide chip has lost its teeth or is stuck with iron filings.

-

Solution: If the teeth are lost, the saw blade must be replaced and returned to the manufacturer for replacement. If it is iron filings, just clean them.

FINAL THOUGHTS

Because aluminum is much more malleable and less forgiving than steel — and more expensive — it’s important to pay close attention when cutting, grinding or finishing the material. Remember that aluminum can be easily damaged with overly aggressive practices. People often measure how much work is being done by the sparks they see. Remember, cutting and grinding aluminum does not produce sparks, so it can be harder to tell when a product is not performing as it should. Check the product after cutting and grinding and look for large aluminum deposits, paying close attention to the amount of material being removed. Applying the proper pressure and reducing the heat generated in the process helps address the challenges presented when working with aluminum.

It’s also important to choose the right product for the application. Look for high-quality, contaminate-free products that are designed for use with aluminum. The right product coupled with key best practices can help produce quality results, while also reducing the time and money spent on rework and scrap material.

Why Choose HERO Aluminum alloy cutting saw blade?

-

JAPAN IMPORTED DAMPING GLUE -

Vibration and noise reduction,protection equipment. -

Japan original high temperature resistant sealantis filled to increase the damping coefficient,reduce the vibration and friction of the blade,and extend the lifetime of the saw blade.At the same time,it can effectively avoid resonance and prolong the service lifetime of the equipment.The measured noise is reduced by 4 -6 decibels,effectively reducing noise pollution. -

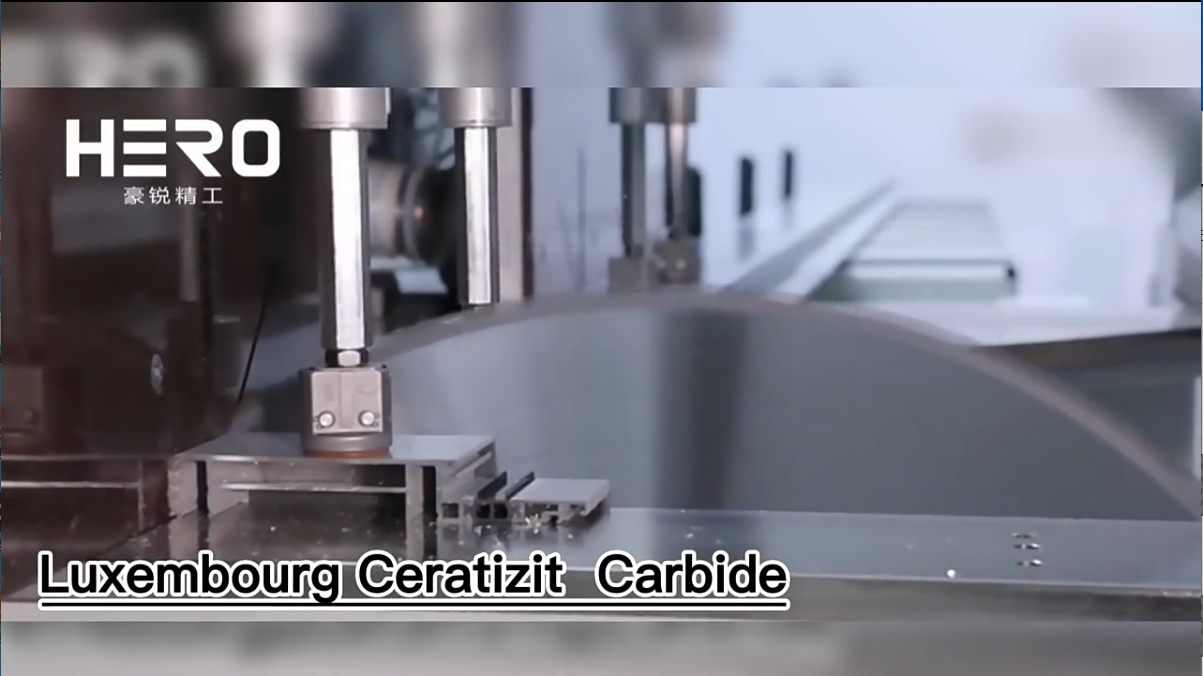

LUXEMBURG CERATIZIT ORIGINAL

CARBIDECERATlZIT original carbide,World top quality,Harder and more long-lasting.

We use CERATIZIT NANO-grade carbide,HRA95°.Transverse rupture strength reach to 2400Pa,and improve the carbide’s resistance of corrosion and oxidation.The carbide superior durability and tenacity better for particle board,MDF cutting,Lifetime is more than 30% compared with usual industrial class saw blade.

Application:

-

All kinds of aluminum, profile aluminum,solid aluminum,aluminum blank. -

Machine:Double mitre saw,Sliding mitre saw, Portable saw.

Post time: Feb-27-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives