Why Does My Circular Saw Blade Keep Breaking?

To make smooth and safe cuts with your saw, it’s important to choose the right type of blade. The type of blade you need will depend on a few things including the type of cut you’re trying to make and the material you’re cutting into. Choosing the right blade will give you better control and precision, and will have a much better lifespan too.

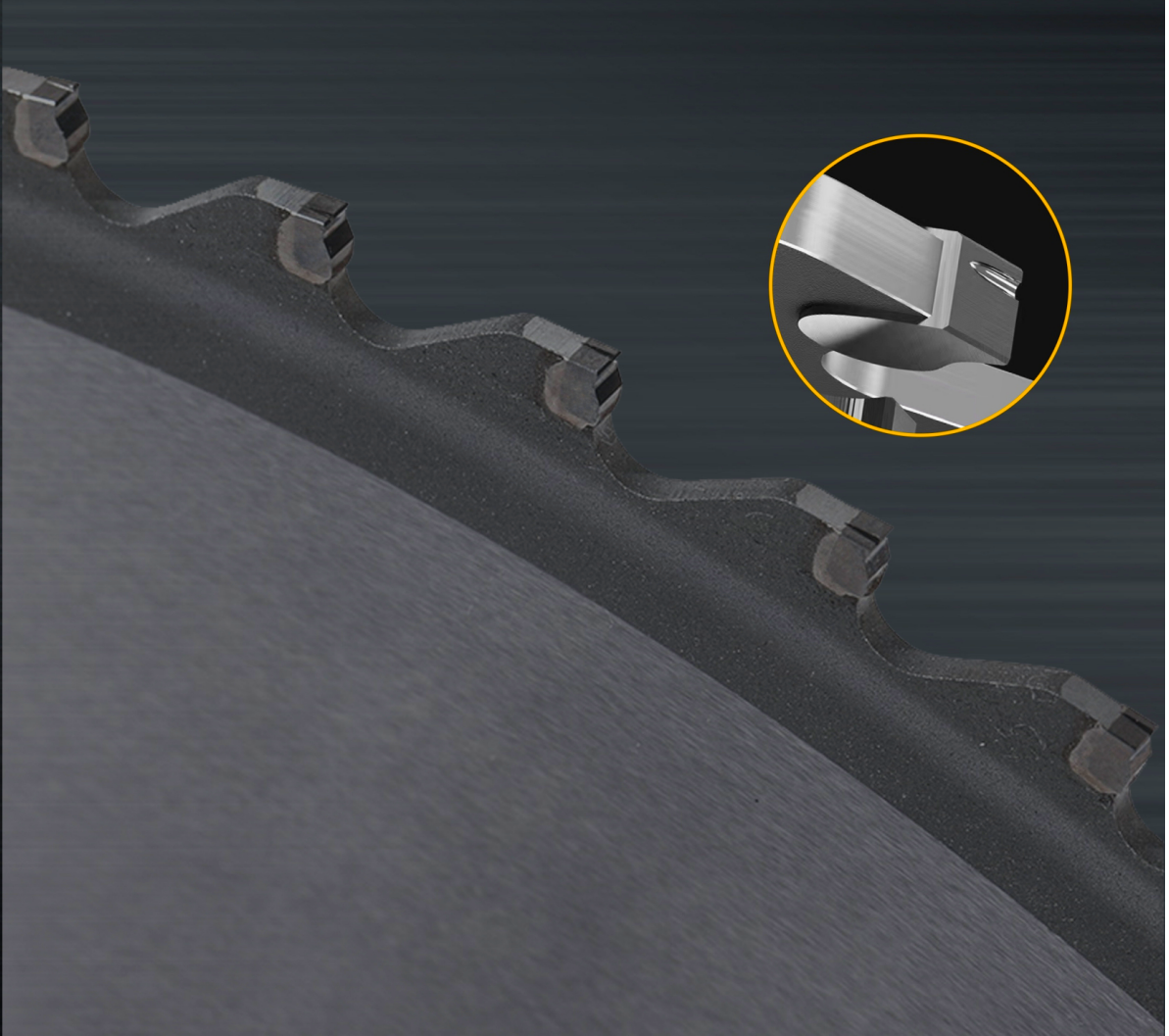

When choosing a saw blade, there are a few things you should consider such as blade size, number of teeth, carbide grade of type, the hook angle and tooth configuration.

HOW TO CHOOSE A CIRCULAR SAW BLADE

Circular saw blades are discs with teeth that can cut a range of materials using a spinning motion. They can be fitted to power saws cutting many materials such as wood, masonry, plastic, or metal.

There are a few things to consider when choosing your circular saw blade. These include:

*The type of material you’re cutting

*Tooth type

*The bore

*Blade thickness

*Depth of the cut

*The material of the blade

*Number of teeth

*The number of revolutions per minute (RPM)

Circular saw blades are essential for cutting through different materials, including steel. However, using a circular saw blade for steel cutting requires proper handling and maintenance to avoid potential issues.

Common Types of Circular Saw Blade Cutting Issues

All tools can encounter issues due to extended usage or misuse, and these issues can hinder workflow. Having an in-depth understanding of your saw blade makes it easier to identify and address any issues that may arise during cutting. Likewise, you can prevent a repeat incident by realizing why your blade broke.

Some of the most common saw blade cutting issues include:

-

Rough cuts

-

Broken teeth

-

Tooth stripping

-

Cracks along the blade

-

Wearing on the back edge of the blade

To assist you in caring for your blades, we’ve explained each of these issues as well as how to solve the problem.

*Rough Cuts

If you notice that your steel-cutting circular saw blade is producing rough or jagged cuts, the issue could be due to a few factors. Using a blade with the wrong tooth count or dull blade teeth are common culprits of rough cuts. Moreover, if the blade tension is off, the blade can vibrate and create uneven cuts.

Preventing This Issue

Sharpen the blade’s teeth regularly and ensure you’re using a blade with the correct tooth count for steel cutting. Additionally, checking and adjusting the blade tension can help improve cut quality. When in doubt about which blade you should use, consult the saw blade manufacturer; they’ll have the precise details you need.

Pro Tip

HERO sells numerous Circular Saw Blade, and we’re always happy to answer our customers’ questions and provide more information on our products.

*Broken Teeth

Saw teeth can break off due to improper use, hitting a foreign object while cutting, or the blade becoming too dull and struggling through the material.

Broken teeth are problematic because they damage the material, affect precision, and throw off balance. If you notice broken teeth on your blade, it’s essential to address the issue immediately by replacing it.

Preventing This Issue

You can prevent teeth from breaking by using the right blade based on the cutting task and material. Regularly clean your blade and remove any metal chips or debris that may have accumulated during cutting.

*Tooth Stripping

Tooth stripping occurs when the blade’s teeth get stripped down, resulting in uneven and jagged cuts. One of the main causes of tooth stripping is using excessive force or trying to cut through materials that are too thick for the blade. Operators may also strip the teeth if they use the wrong type of coolant, feed the material too fast, or use the wrong cutting technique.

Preventing This Issue

To avoid tooth striping, ensure you’re using sharp blades and following proper cutting techniques. Use a coolant designed for steel cutting and gradually feed the material through at an appropriate speed.

*Cracks on the Side of the Blade

Cracks or deformities along the side of the blade cause concern, as they can lead to vibrations and poor cuts. If not addressed, these cracks may also grow and eventually lead to the blade breaking, which can create safety hazards for operators.

Preventing This Issue

Avoid this issue by first understanding the root cause of side loading. The problem is often caused by cutting materials that are too hard or dense for the blade. Your blade may also crack on the sides if the guides are too tight. Taking care not to cut materials that are unsuitable for your blade will prevent the likelihood of cracks forming.

*Wearing on the Back Edge

If you notice that the back edge of your saw blade’s teeth wear down faster than the front, this could be a sign of incorrect cutting techniques. Pushing too hard or using excessive force can cause this issue and may also lead to overheating and warping of the blade.

Preventing This Issue

To avoid this problem, use proper cutting techniques and avoid putting too much pressure on the blade. Let the saw do the work and guide it through the cut without forcing it.

Tips for Maintaining Your Circle Saw Blades

When it comes to troubleshooting steel-cutting circular saw blade issues, you should also know how to care for your tool to reduce the risk of damage. Preventing steel-cutting circular saw blade issues is the best way to ensure smooth operations and high-quality results. Taking care of your blades and following these tips can prevent future problems:

*Choose the right blade for the job

*Properly store blades

*Take care of your tool

*Use lubricants as needed

The more you care for your blades, the longer they will last and perform at their best. Remember to regularly examine and maintain your saw to ensure it’s in optimal condition.

Use the Right Blade

High-speed steel and carbide-tipped blades are the most common blades used for metal cutting, but the exact blade you need to use depends on the material you work with. Before buying a blade, read the product description to determine the type of material it can cut. Keep in mind that not all blades designed for cutting steel can cut stainless steel.

Pro Tip

If you work with ferrous and non-ferrous metals, keep these blades in separate locations to avoid mixing them up.

Prioritize Proper Blade Storage and Handling

Properly storing your circular saw blades is more than just a good habit; it’s a necessity. Keep blades away from moisture and heavy vibrations. Ensure they’re completely dry before stowing them to avoid pitting and other forms of corrosion.

Handle your blades with the respect they deserve. Use the dull side of a piece of wood to tap out metal chips; never use your bare hands, as your skin’s oils can cause corrosion.

Regularly Clean It

A blade’s life is a series of cycles—cutting, cooling, clearing, and cutting again. Each cycle maintains the blade’s integrity. Always clean your blades after work, remove any built-up residues, and set them to rest, as proud and gleaming as when you first took them out of the package.

Use Lubricant

Depending on the type of blade and material, you may need to use lubricant. Review your blade’s usage requirements in the product description or manual to determine whether you need lubricant and the type that is best suited to your blade.

Shop for Quality Circular Saw Blades

HERO offers a wide range of high-quality circular saw blades for metal cutting. Check out our collections of saw blades for steel & wood & metal cutting designed for professionals in the metal fabrication industry. Our circle saw blades provide precision, durability, and superior performance.

Post time: May-30-2024

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives