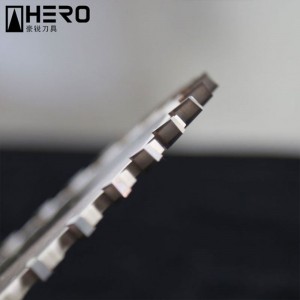

PCD German Technology High Quality Circular Saw Blade for Scoring

Product Overview

Raw Materials: PCD segment, German imported steel plate 75CR1 and Japan imported steel plate SKS51.

Brand: HERO, LILT

Features

1. Used to cut wood panels, as well as other saw blades for cutting aluminum and fiber cement.

2. Used on equipment such as Biesse, Homag, sliding saws, and portable saws.

3. A surface chrome coating.

4. The PCD segment offered a longer tool life and blade longevity, maximizing cutting life and material finish in a range of materials.

5. The anti-vibration design lowers vibration and promotes high performance.

6. The standard length of a PCD tooth is 6.0mm, however it can be adjusted to meet special needs, such as 6.8mm and 7mm.

Parameters

1. Saw blades for panels-usually diamter from 100mm-200mm, number of teeth from 24-40T, kerf thickness usually 2.8-3.6, 3.0-4.0, 4.3-4.3, 4.7-5.7mm

2. Saw blades for cutting aluminum, usually diameter from 305mm to 550mm, teeth number 100T, 120T, 144T.

3. Saw blades for fiber cement, typically with fewer teeth.

4. Shown below are some common saw blade parameters for panel size saw blades with quick delivery.

The specifications that are not given require a few extra days for production.

|

OD(mm) |

Bore |

Kerf Thickness |

Plate Thickness |

Number of Teeth |

Grind |

||||

|

120 |

20 |

2.8-3.6 |

2.2 |

12+12 |

conical |

||||

|

120 |

22 |

2.8-3.6 |

2.2 |

12+12 |

conical |

||||

|

120 |

22 |

2.8-3.6 |

2.2 |

12+12 |

U |

||||

|

120 |

20 |

3.0-4.0 |

2.2 |

24 |

conical |

||||

|

120 |

22 |

3.0-4.0 |

2.2 |

24 |

conical |

||||

|

160 |

30 |

3.3-4.3 |

2.2 |

36 |

conical |

||||

|

160 |

30 |

4.3-5.3 |

3.2 |

36 |

conical |

||||

|

160 |

45 |

4.3-5.3 |

3.2 |

36 |

conical |

||||

|

180 |

30 |

4.3-5.3 |

3.2 |

36 |

conical |

||||

|

180 |

30 |

4.3-5.3 |

3.2 |

40 |

conical |

||||

|

180 |

45 |

4.3-5.3 |

3.2 |

40 |

conical |

||||

|

200 |

45 |

4.3-5.3 |

3.2 |

36 |

conical |

||||

|

200 |

50 |

4.3-5.3 |

3.2 |

36 |

conical |

||||

|

200 |

75 |

4.3-5.3 |

3.2 |

40 |

conical |

||||

|

200 |

45 |

4.7-5.7 |

3.2 |

40 |

conical |

||||

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives