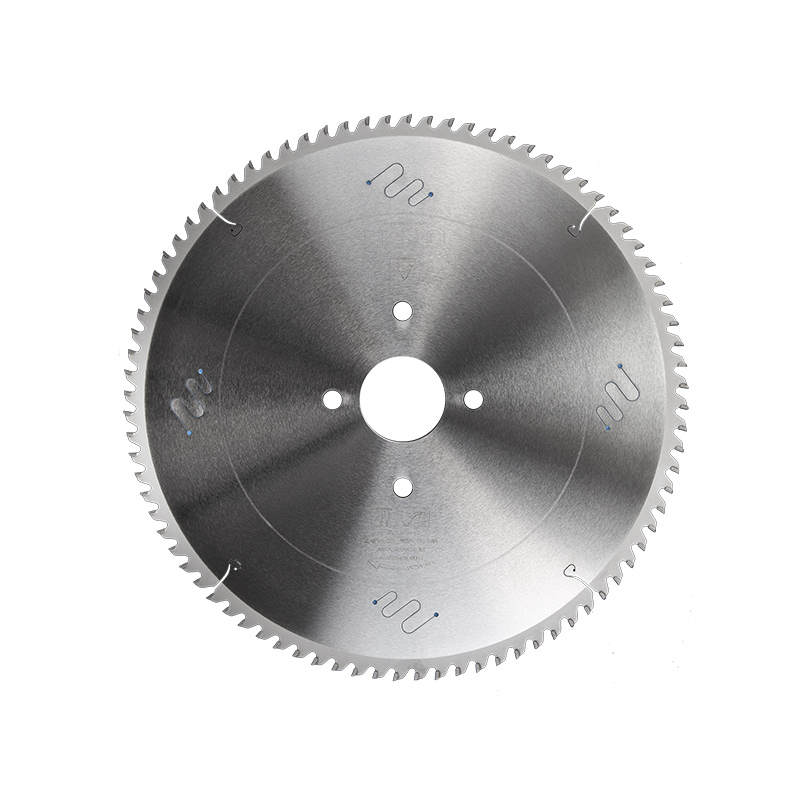

PCD Saw Blade for Panel Sizing Saw Blade

Product Overview

Raw Materials: PCD segment, German imported steel plate 75CR1 and Japan imported steel plate SKS51.

Brand: HERO, LILT

Features

1. Used to cut wood panels and to provide additional saw blades for cutting particle board, MDF, and melamine board.

2. Used on various equipment, such as the Biesse, Homag, and beam saw.

Advantage:

1. Silent design with Japan damping and chrome coating for cutting without noise.

2. The PCD component promised to extend the life of the tools and the blades.

3. The anti-vibration design minimizes vibration and enhances performance, preventing chipping and finishing cutting.

4. Tight procedures that ensure the saw blades are of a high grade, increase production, decrease the amount of time needed for replacements, and reduce tooling costs

5. Using Gerling machines to complete the brazing process and sandwich silver-copper-silver technology to strengthen teeth.

Highlight:

● 1. Maintain strict temperature control while processing the PCD segment.

● 2. To complete the grinding process, which is the most crucial step for PCD saw blades, use a copper electro sanding wheel.

● 3. Standard length of PCD tooth is 6.0mm,can be customized according to specific requirements, for example 6.8mm and 7mm. The more longer of PCD segment the more lifetime.

● 4. The biggest advantage is the longer tools life, about 50 times more than TCT carbide tipped saw blade. For example you spend 5 times more money to get a product that working 50 times longer, and can continue working 30 days with one replacement from the machine, which also saves you a lot of time replacing blades. What would your choice be?

Parameters

1. This product is typically developed to cut for cutting wood panels, particle,laminated and MDF on table saws and panel sizing saws.

2 .Compare with tungsten carbide and steel circular saw blades, pcd saw blade are harder and significantly more durable, performing 30-50 times longer tool life, and this saves both time and money.

3. Machines: double mitre saw, panel saw, cut-off saw and other CNC machines etc.

4. Application: very accurate for 45 degree and 90 degree joint cut.Particularly welcomed on aluminum window or doors producers.

|

OD(mm) |

Bore |

Kerf Thickness |

Plate Thickness |

Number of Teeth |

Grind |

|

350 |

30 |

4.4 |

3.2 |

72 |

TCG |

|

350 |

30 |

4.4 |

3.2 |

84 |

TCG |

|

380 |

60 |

4.4 |

3.2 |

72 |

TCG |

|

380 |

60 |

4.4 |

3.2 |

84 |

TCG |

|

380 |

60 |

4.4 |

3.2 |

96 |

TCG |

|

400 |

60 |

4.4 |

3.2 |

72 |

TCG |

|

400 |

60 |

4.4 |

3.2 |

84 |

TCG |

|

400 |

75 |

4.4 |

3.2 |

84 |

TCG |

|

400 |

60 |

4.4 |

3.2 |

96 |

TCG |

|

450 |

60 |

4.4 |

3.2 |

72 |

TCG |

|

450 |

60 |

4.8 |

3.5 |

84 |

TCG |

|

450 |

60 |

4.8 |

3.5 |

96 |

TCG |

TCT Saw Blade

TCT Saw Blade HERO Sizing Saw Blade

HERO Sizing Saw Blade HERO Panel Sizing Saw

HERO Panel Sizing Saw HERO Scoring Saw Blade

HERO Scoring Saw Blade HERO Solid Wood Saw Blade

HERO Solid Wood Saw Blade HERO Aluminum Saw

HERO Aluminum Saw Grooving Saw

Grooving Saw Steel Profile Saw

Steel Profile Saw Edge Bander Saw

Edge Bander Saw Acrylic Saw

Acrylic Saw PCD Saw Blade

PCD Saw Blade PCD Sizing Saw Blade

PCD Sizing Saw Blade PCD Panel Sizing Saw

PCD Panel Sizing Saw PCD Scoring Saw Blade

PCD Scoring Saw Blade PCD Grooving Saw

PCD Grooving Saw PCD Aluminum Saw

PCD Aluminum Saw PCD Fiberboard Saw

PCD Fiberboard Saw Cold Saw for Metal

Cold Saw for Metal Cold Saw Blade for Ferrous Metal

Cold Saw Blade for Ferrous Metal Dry Cut Saw Blade for Ferrous Metal

Dry Cut Saw Blade for Ferrous Metal Cold Saw Machine

Cold Saw Machine Drill Bits

Drill Bits Dowel Drill Bits

Dowel Drill Bits Through Drill Bits

Through Drill Bits Hinge Drill Bits

Hinge Drill Bits TCT Step Drill Bits

TCT Step Drill Bits HSS Drill Bits/ Mortise Bits

HSS Drill Bits/ Mortise Bits Router Bits

Router Bits Straight Bits

Straight Bits Longer Straight Bits

Longer Straight Bits TCT Straight Bits

TCT Straight Bits M16 Straight Bits

M16 Straight Bits TCT X Straight Bits

TCT X Straight Bits 45 Degree Chamfer Bit

45 Degree Chamfer Bit Carving Bit

Carving Bit Corner Round Bit

Corner Round Bit PCD Router Bits

PCD Router Bits Edge Banding Tools

Edge Banding Tools TCT Fine Trimming Cutter

TCT Fine Trimming Cutter TCT Pre Milling Cutter

TCT Pre Milling Cutter Edge Bander Saw

Edge Bander Saw PCD Fine Trimming Cutter

PCD Fine Trimming Cutter PCD Pre Milling Cutter

PCD Pre Milling Cutter PCD Edge Bander Saw

PCD Edge Bander Saw Other Tools & Accessories

Other Tools & Accessories Drill Adapters

Drill Adapters Drill Chucks

Drill Chucks Diamond Sand Wheel

Diamond Sand Wheel Planer Knives

Planer Knives